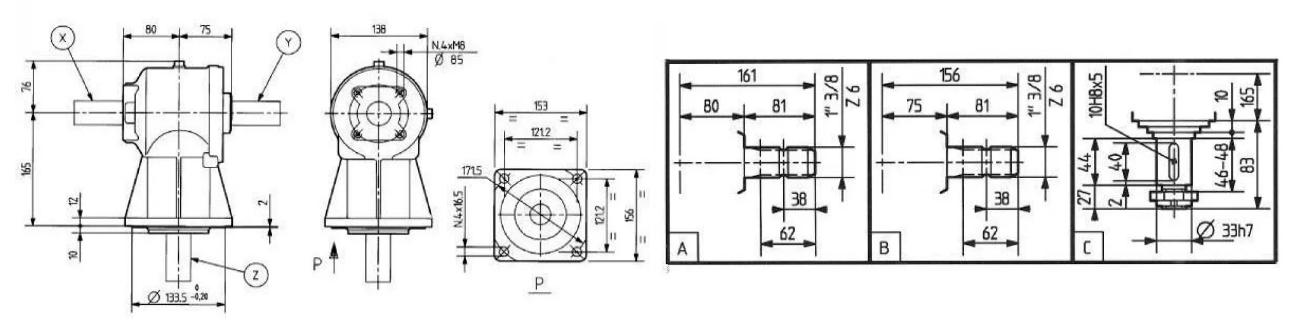

Specifications of Rotary Mower Gearbox LF-141A (1:2.83)

| Description |

Rotary Mower Gearboxes – Replacement of Comer Gearbox LF-141A 1:2.83

|

|---|---|

| Application |

Mowers

|

| Consists of |

|

| Technical information |

|

| Contains oil |

No

|

| Max. oil capacity |

0.5 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| Weight |

14 kg

|

| Gear arrangement Increasing |

23 – 24

|

| Input power kW / HP Increasing |

14.7 / 20 kW/HP

|

| Input shaft Increasing |

Y

|

| Output Torque DaNm Increasing |

8.9 daNm

|

| Ratio Increasing |

1: 2.83

|

| Ratio Reducing |

2.83: 1

|

| Shaft Y |

1 3/8″ (6) (B)

|

| Shaft Z |

33 (C)

|

Benefits of Rotary Mower Gearbox LF-141A (1:2.83)

The rotary mower gearbox LF-141A is a top choice for agricultural rotary mower applications, offering numerous advantages. Here are its key benefits:

1. Efficient Mowing

- With a gear ratio of 1:2.83, the LF-141A delivers the ideal balance of speed and torque for efficient mowing.

- Ensures optimal performance and ease of operation for agricultural machinery, enabling superior results.

2. Exceptional Durability

- Built from high-quality materials to handle the rigorous demands of agricultural use.

- Features robust components, including a heavy-duty input shaft, seals, gears, and bearings, ensuring long-lasting reliability.

3. Easy Installation and Maintenance

- Compact and user-friendly design allows for straightforward installation.

- Provides convenient access to components, simplifying lubrication and part replacement when necessary.

4. Versatile Compatibility

- Designed to work seamlessly with most tractor types using an agricultural PTO (Power Take-Off) shaft.

- Offers flexibility for a wide range of agricultural equipment and tasks.

5. Low Maintenance Requirements

- Constructed with high-quality materials to minimize maintenance needs.

- Perfect for busy agriculturalists aiming to maximize productivity without frequent downtime.

6. Enhanced Equipment Performance

- Boosts the efficiency and reliability of rotary mowers and other agricultural tools.

- Helps complete tasks faster and more effectively, improving overall operational outcomes.

The rotary mower gearbox LF-141A combines durability, compatibility, and efficiency in a compact design. It enhances equipment performance, reduces maintenance demands, and simplifies installation, making it a dependable solution for agriculturalists seeking reliable and effective rotary mowing equipment.

How to Remove the Rotary Mower Gearbox from a Rotary Mower

Removing the rotary mower gearbox is a straightforward process but requires careful attention to safety and precision. Follow these steps:

1. Disconnect the Power Source

- Ensure the tractor or mower is turned off and disconnected from the power source to prevent any accidental activation.

2. Remove the Cutting Blades

- Detach the cutting blades from the mower deck to gain access to the gearbox.

- Use the appropriate tools, such as a wrench or socket, to safely remove the blades.

3. Locate and Remove Mounting Bolts

- Identify the bolts securing the gearbox to the mower deck.

- Use a wrench or socket set to loosen and remove these bolts, setting them aside for reassembly.

4. Disconnect the Input and Output Shafts

- Detach the input and output shafts from the gearbox.

- This may involve removing couplings, pins, or other attachments connecting the shafts.

5. Lift and Remove the Gearbox

- Carefully lift the gearbox off the mower deck.

- If the gearbox is heavy, consider enlisting help to ensure safety during removal.

6. Inspect the Gearbox

- Examine the gearbox for signs of wear or damage, including the gears, seals, and bearings.

- Clean and assess its condition to determine if repair or replacement is necessary.

7. Repair or Replace as Needed

- Follow the manufacturer’s instructions for any required repairs.

- If the gearbox is beyond repair, obtain a suitable replacement compatible with your mower.

8. Reinstallation

- Reverse the steps above to reinstall the gearbox, ensuring all components are securely fastened.

- Use the recommended torque specifications for mounting bolts and check alignment before use.

Safety Tips

- Always wear protective gloves and safety goggles.

- Keep loose clothing and body parts away from sharp or moving components.

- Refer to the mower’s user manual for specific guidelines and torque values.

By following these steps, you can safely and efficiently remove the rotary mower gearbox, ensuring smooth maintenance or replacement procedures.

Similarities and Differences Between Rotary Mower Gearbox and Flail Mower Gearbox

Similarities

- Function

- Both gearboxes are designed to transfer power from the tractor’s PTO shaft to the mower’s cutting mechanism.

- They ensure the proper speed and torque for effective mowing operations.

- Durability

- Both are built with high-quality materials like hardened steel gears and robust housings to withstand the demanding conditions of agricultural and landscaping applications.

- Compatibility with PTO Systems

- Both gearboxes are compatible with standard tractor PTO systems and require proper alignment and attachment.

- Maintenance Requirements

- Regular maintenance, such as lubrication and inspection for wear and tear, is essential for both types to ensure longevity and optimal performance.

- Applications

- Both are used in agricultural and landscaping equipment, though the type of cutting and field conditions may differ.

Differences

| Aspect | Rotary Mower Gearbox | Flail Mower Gearbox |

|---|---|---|

| Cutting Mechanism | Powers rotating blades that spin horizontally. | Drives a horizontal drum with flail knives or hammers. |

| Cutting Style | Produces a clean and uniform cut, suitable for grass and light vegetation. | Provides a finer cut and mulching effect, ideal for dense brush and debris. |

| Torque Requirements | Lower torque needed for lighter cutting tasks. | Requires higher torque to handle heavy-duty and dense vegetation. |

| Speed Ratios | Typically higher-speed output for faster blade rotation. | Lower-speed output for better control over flail movement. |

| Field Applications | Best for open fields, lawns, and lighter agricultural use. | Preferred for rough terrain, overgrown areas, and heavy-duty clearing. |

| Wear and Tear | Less wear due to fewer moving parts. | Higher wear potential due to numerous flail attachments. |

| Noise Levels | Generally quieter operation. | May produce more noise during operation due to multiple moving parts. |

While both rotary mower and flail mower gearboxes are integral to their respective equipment, they differ significantly in their design, function, and application. Rotary mower gearboxes are best for precision mowing and lighter tasks, while flail mower gearboxes excel in heavy-duty cutting and mulching. Selecting the appropriate gearbox depends on the specific mowing needs and field conditions.

|

|

| Flail Mower Gearboxes | Rotary Mower Gearboxes |

PTO Shaft for Rotary Mower Gearboxes

The PTO (Power Take-Off) shaft plays a crucial role in the operation of a rotary mower gearbox. It transfers mechanical power from the tractor’s engine to the gearbox, which then drives the mower blades. Proper selection and maintenance of the PTO shaft are essential for efficient and safe operation. Below are key considerations for choosing and maintaining a PTO shaft for rotary mower gearboxes:

1. Size and Compatibility

- PTO shafts come in various lengths and diameters, making it important to choose one that is compatible with both the rotary mower gearbox and your tractor’s engine horsepower.

- Ensure the PTO shaft fits correctly with the tractor’s PTO output and the mower’s input shaft to prevent issues during operation.

2. Correct Length

- The length of the PTO shaft should be adjusted to allow for smooth and efficient operation of the rotary mower.

- Accurately measure the distance between the tractor’s PTO output and the mower gearbox to determine the required shaft length. This ensures optimal performance and avoids potential damage.

3. Speed Considerations

- It is crucial to avoid exceeding the recommended speed for the PTO shaft, as over-speeding can lead to damage to the gearbox or other parts, and pose significant safety risks.

- Always adhere to the manufacturer’s specified speed limits for both the PTO shaft and the rotary mower gearbox to prevent operational failures.

4. Quality and Durability

- Choose a high-quality PTO shaft from a trusted manufacturer to ensure longevity and reliability, especially under demanding or heavy-duty conditions.

- Durable shafts are vital for the longevity of the entire mowing system, reducing the need for frequent replacements or repairs.

5. Regular Maintenance

- Regular lubrication of the PTO shaft’s cross and bearings is essential to keep the shaft running smoothly and prevent wear.

- Inspect the shaft, bearings, and greasing system periodically for damage or wear, and replace any worn or damaged components promptly to avoid costly repairs or system failure.

6. Safety

- PTO shafts can be dangerous if not handled properly. Always follow safety protocols during installation, operation, and maintenance.

- Ensure that hands, clothing, and hair are kept away from moving parts, and never attempt to touch or adjust the shaft while the machinery is running.

Selecting and maintaining the right PTO shaft for your rotary mower gearbox ensures safe, efficient, and reliable operation of your mower. By paying attention to size, length, speed, and maintenance, you can extend the life of your equipment, minimize downtime, and maximize performance while ensuring safe operation.

|

|

About FMP

FMP, headquartered in Italy, is a renowned leader in the research, development, and manufacturing of high-quality gearboxes, reducers, and engineering machinery. With a deep commitment to innovation and technical excellence, FMP has carved a niche for itself as a pioneer in the mechanical engineering sector. The company is driven by a culture of nurturing talent and fostering creativity, making it a trusted partner for global industries seeking top-notch engineering solutions.

Diverse Product Portfolio

FMP offers a wide array of specialized products, including:

- Spiral Bevel Gearboxes

- Spur Gearboxes

- Worm Gearboxes

- Cylindrical Gearboxes

- High-Pressure Cast Valve Bodies and Housings

These products are designed and engineered to meet the rigorous demands of various industrial applications, ensuring high performance, efficiency, and reliability.

Wide-Ranging Applications

FMP’s products find applications across a diverse range of industries, including:

- Agriculture: FMP gearboxes are widely used in agricultural machinery, including rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. These robust gearboxes help improve the efficiency and reliability of machinery used for essential farming tasks.

- Industrial Equipment: FMP also supplies gearboxes and related components for industrial machinery, such as oil extraction equipment, marine applications, and hydraulic systems for engineering projects, ensuring high performance in critical applications.

- Hydraulic Engineering: The company provides a variety of hydraulic components, serving industries that require precision and reliability, from construction to energy sectors.

Advanced Manufacturing Processes

FMP is proud of its robust technical capabilities and advanced manufacturing processes. The company employs a highly skilled workforce, cutting-edge technology, and a meticulous production process to deliver top-tier products:

- Product Design: FMP works closely with customers to develop tailored solutions, ensuring that each product meets specific requirements in terms of gearbox type, material, and dimensions.

- Material Preparation: FMP selects only the highest-grade materials such as cast iron and aluminum alloys, ensuring durability and longevity in all their products.

- Precision Machining: Components like gears, shafts, and housings undergo advanced machining techniques, including turning, milling, and grinding, to achieve precise tolerances and optimal performance.

- Assembly: Gears, bearings, and shafts are expertly assembled into the housing, ensuring precise alignment and adequate lubrication for long-lasting operation.

- Heat Treatment: Gearboxes undergo heat treatment processes to enhance strength and wear resistance, ensuring they stand up to demanding operational conditions.

- Surface Treatment: To improve corrosion resistance and enhance the appearance of the gearboxes, FMP applies surface treatments like polishing and powder coating.

- Quality Control: Rigorous inspections and testing are carried out at every stage of production to ensure each product meets strict performance and durability standards. FMP’s quality control processes ensure that each gearbox performs reliably over time.

Industry Reputation

FMP’s unwavering dedication to quality, innovation, and customer satisfaction has earned it an exceptional reputation within the manufacturing industry. The company’s philosophy revolves around craftsmanship, technological advancement, and providing long-term value to clients. FMP’s success is built on the continuous pursuit of excellence, ensuring that it meets the ever-evolving needs of the industries it serves.

Partner with Us

FMP is always open to collaboration opportunities with global clients and partners. Whether you are looking for customized solutions or off-the-shelf products, FMP is committed to providing high-quality gearboxes and engineering components that exceed expectations. For inquiries about our products and services, please don’t hesitate to contact us via phone or email. We are here to deliver tailored solutions that meet your unique needs and drive your business forward.

Author: CX