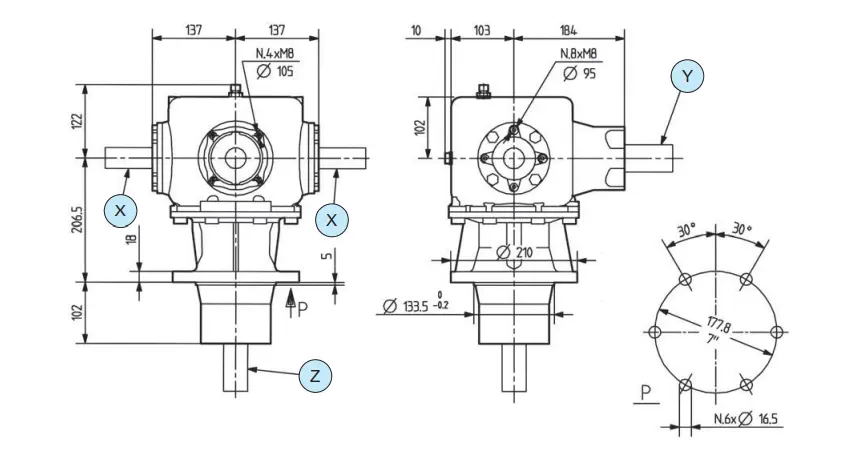

Rotary Mower Gearbox TF-285B Specifications

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type | Input | ||

| X | Y | Z | |||||

| 1.86 | 1000 | 91.9 | 709 | 1” 3/8 Z21 | 1” 3/4 Z20 | Hub connection | Y |

Advantages of Rotary Mower Gearbox

Rotary mowers equipped with a high-quality gearbox offer numerous advantages, making them an essential tool for landscaping, agriculture, and grounds maintenance. These advantages stem from the gearbox’s ability to efficiently transfer power, reduce wear, and enhance the overall performance of the mower. Here are some key benefits of using a rotary mower gearbox:

- Efficient Power Transmission

A rotary mower gearbox plays a crucial role in transferring power from the tractor’s engine to the mower blades. This efficient transmission ensures that the blades rotate at the optimal speed and torque, allowing the mower to cut grass effectively, even in tough conditions. This is especially important for large-scale operations where consistency and efficiency are key. - Durability and Longevity

Rotary mower gearboxes are designed to withstand heavy-duty use and harsh conditions. With sturdy construction, often made from high-quality materials like cast iron or aluminum alloys, these gearboxes are resistant to wear, corrosion, and stress. This durability ensures that the gearbox can operate smoothly for extended periods, reducing the need for frequent repairs or replacements. - Reduced Maintenance and Operating Costs

Because of their robust design and efficient power transmission, rotary mower gearboxes require less maintenance than other types of mower drives. The proper lubrication of internal components, such as gears and bearings, helps minimize friction, wear, and overheating, which leads to reduced operating costs and fewer maintenance interventions. This means more uptime and fewer interruptions for repairs. - Improved Cutting Performance

A well-designed gearbox ensures that the mower blades achieve the right speed and torque, resulting in a clean and consistent cut. Whether it’s grass, weeds, or small brush, the gearbox ensures that the mower delivers superior cutting performance even under challenging conditions. The gearbox helps the mower handle thick, dense vegetation and uneven terrain more effectively. - Versatility and Customization

Rotary mower gearboxes come in various configurations, such as single-speed or multi-speed models, allowing for flexibility in different applications. Many manufacturers, including FMP, offer customized solutions to meet specific performance requirements, such as adjusting the cutting height or providing additional torque for tough mowing tasks. This versatility allows the gearboxes to serve a wide range of industries, from agriculture to municipal landscaping. - Safety Features

Many rotary mower gearboxes come equipped with safety features, such as overrun clutches or disengagement mechanisms, which prevent damage to the gearbox and mower blades when the engine is turned off. These features also help protect the operator from accidents and reduce the risk of mechanical failure. - Compact and Easy to Install

Rotary mower gearboxes are typically designed to be compact and easy to install on various types of mowers and machinery. Their design ensures that they are not only efficient in terms of power transmission but also easy to integrate into different systems, making them an excellent choice for both OEM manufacturers and end-users.

In conclusion, the rotary mower gearbox is a vital component that enhances the performance, reliability, and cost-effectiveness of mowing equipment. Its ability to efficiently transfer power, reduce maintenance, and improve cutting performance makes it an indispensable part of modern rotary mowers used in agricultural, industrial, and landscaping applications.

About FMP

FMP, based in Italy, is a leading innovator in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. Known for its commitment to quality, continuous improvement, and talent development, FMP has earned recognition both locally and internationally. With a strong reputation in the mechanical engineering sector, the company is a trusted partner across various industries.

FMP offers an extensive range of high-performance products, including spiral bevel gearboxes, spur gearboxes, worm gearboxes, cylindrical gearboxes, and high-pressure cast valve bodies and housings. These products are engineered with precision to meet the diverse needs of industrial and agricultural applications, providing reliability and durability.

The company’s gearboxes and components serve multiple sectors, such as agriculture, oil extraction, marine systems, and hydraulic engineering. In agriculture, FMP powers vital machinery like rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. This wide application range highlights FMP’s versatility and its ability to offer solutions that enhance operational efficiency across industries.

FMP’s manufacturing process is built on advanced techniques and rigorous quality control standards. From product design to final assembly, each item is crafted using premium materials such as cast iron and aluminum alloys. Precision machining methods ensure high accuracy, while thorough inspections guarantee reliability and long-term performance. FMP’s focus on quality, alignment, and wear resistance ensures its products continue to meet the highest standards.

As a forward-thinking company, FMP is dedicated to customer satisfaction and ongoing innovation. The company is open to global partnerships, offering customized solutions tailored to client needs. To learn more about FMP’s products or explore collaboration opportunities, prospective partners can easily contact the company via phone or email, reinforcing FMP’s commitment to exceptional service and high-quality solutions.

Author: CX