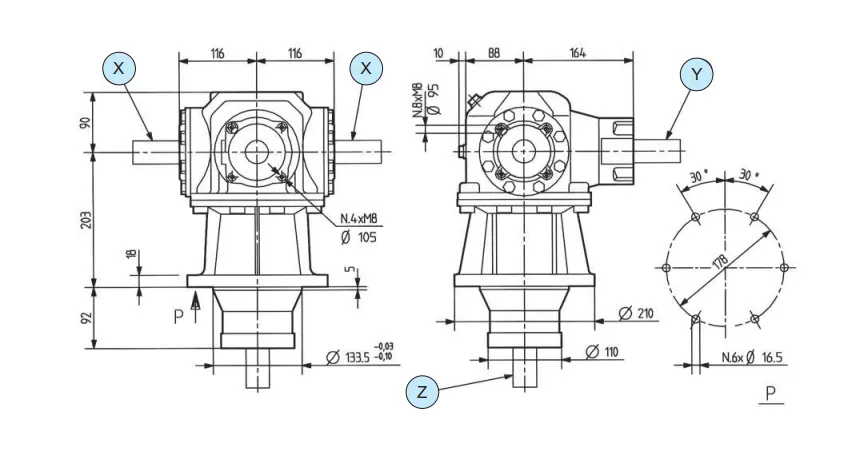

Rotary Mower Gearbox TF-26A Specifications

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type | Input | ||

| X | Y | Z | |||||

| 1.84 | 540 | 66.0 | 615 | 1” 3/8 Z6 | 1” 3/8 Z6 | Hub connection | Y |

| 1.47 | 540 | 66.0 | 770 | 1” 3/8 Z6 | 1” 3/8 Z6 | Hub connection | Y |

Features of Rotary Mower Gearbox

The gearbox is a vital component of a rotary mower, ensuring that the mower operates efficiently and effectively. Rotary mowers are widely used by landscapers, gardeners, and in agricultural settings for their ability to cut grass, weeds, and brush with ease. A high-quality rotary mower gearbox enhances the mower’s overall performance, durability, and longevity, making it essential for smooth operation in various conditions.

One of the key features of a rotary mower gearbox is its durable housing, typically made from strong materials such as cast iron or aluminum alloys. The housing serves to protect the internal components from harsh environmental factors, such as dirt, moisture, and debris. This robust construction ensures that the gearbox remains intact and performs reliably under demanding conditions, including heavy-duty mowing tasks in fields or rough terrains.

Another important feature is the bearings that support the rotating shaft and gears inside the gearbox. Bearings reduce friction, allowing the internal components to rotate smoothly and efficiently. They also help to minimize wear and tear, ensuring that the gearbox can function for an extended period without the need for frequent repairs. Proper lubrication of the bearings is crucial to prevent overheating and maintain optimal performance, which is why many gearboxes come with an integrated lubrication system that ensures all moving parts are well-oiled.

The seals in the gearbox play a crucial role in preventing the entry of contaminants, such as dirt, grass clippings, and water. These seals help maintain the integrity of the lubrication inside the gearbox and protect the internal gears from damage. Without proper sealing, debris could enter the gearbox and cause significant damage to the components, resulting in costly repairs and downtime. Therefore, seals ensure the gearbox remains efficient and extends the overall life of the mower.

Some advanced rotary mower gearboxes come with additional features like adjustable gears that allow operators to modify the cutting height. This feature is especially useful in varying mowing conditions, such as when transitioning from mowing grass to cutting through thicker vegetation. Being able to adjust the height ensures a cleaner and more efficient cut, providing the operator with greater control over the mowing process. Furthermore, certain gearboxes also include a clutch mechanism that disengages the blades when the mower is not in use. This helps prevent unnecessary wear on the blades and reduces the risk of damage when the mower is idle.

In addition to the TF-26A rotary mower gearbox, we also offer a variety of other agricultural gearboxes designed for specific applications. Whether for heavy-duty industrial use or lighter-duty tasks, our range of gearboxes ensures that every user can find the right gearbox to match their mower and operational needs.

In summary, a high-quality rotary mower gearbox is essential for ensuring efficient operation, minimizing wear and tear, and extending the life of the mower. With features like durable housing, efficient bearings, protective seals, adjustable gears, and clutch mechanisms, these gearboxes contribute to the smooth and reliable performance of rotary mowers across a variety of environments.

PTO Shafts for Sale

At FMP, we offer a comprehensive selection of high-quality PTO (Power Take-Off) shafts specifically designed for use with agricultural gearboxes, including rotary mower gearboxes. The PTO shaft plays a vital role in transmitting mechanical power from the tractor’s engine to the agricultural machinery. It operates at speeds ranging from 540 to 1,000 RPM, depending on the specific requirements of the application.

Our PTO shafts are engineered with durability and efficiency in mind, featuring robust construction and yokes at both ends to connect seamlessly with the gearbox. These shafts come in various torque ratings, allowing you to choose the right option based on your machine’s power needs. Whether you are working with light-duty or heavy-duty equipment, we offer PTO shafts tailored to provide optimal performance.

In addition to our wide range of standard PTO shafts, FMP also offers customized solutions to meet the specific requirements of your machinery. Whether you need adjustments in length, torque, or other specifications, we can design and manufacture PTO shafts to suit your exact needs.

If you’re looking for high-performance PTO shafts that ensure smooth power transfer and long-lasting operation, don’t hesitate to contact us. Reach out today for more information or to discuss your custom PTO shaft requirements!

About FMP

FMP, located in Italy, is a well-respected leader in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. Known for its focus on innovation, quality, and talent development, FMP has established itself as a prominent player in the mechanical engineering sector. The company has earned both domestic and international recognition for its dedication to continuous improvement and excellence, making it a trusted partner in a wide range of industries.

FMP offers an extensive selection of high-performance products, including spiral bevel gearboxes, spur gearboxes, worm gearboxes, cylindrical gearboxes, and high-pressure cast valve bodies and housings. These products are designed with precision to meet the unique needs of various applications. Whether for heavy-duty industrial machinery or specialized agricultural equipment, FMP’s gearboxes deliver reliable performance and durability.

The company’s gearboxes and components are widely used across industries, with applications spanning agriculture, oil extraction, marine systems, and hydraulic engineering. In agriculture, FMP products power essential machinery such as rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. This versatility demonstrates FMP’s ability to serve diverse industries with high-quality solutions that enhance efficiency and productivity.

FMP’s commitment to advanced manufacturing excellence is reflected in its rigorous production processes. From the initial design stage to final assembly, each product is crafted to meet the highest standards of quality. The company uses only high-grade materials, such as cast iron and aluminum alloys, ensuring durability and optimal performance. Precision machining techniques, including turning and milling, are employed to fabricate each component with accuracy. FMP’s quality control processes ensure that every product performs reliably, with attention to alignment, lubrication, and long-term wear resistance.

As a company that values customer satisfaction and innovation, FMP continues to build on its strong reputation for delivering high-performance products. The company is open to global partnerships and collaborations, offering customized solutions to meet specific customer needs. For more information or to discuss potential collaborations, clients can easily contact FMP via phone or email, reinforcing the company’s commitment to exceptional service and high-quality solutions.

Author: CX