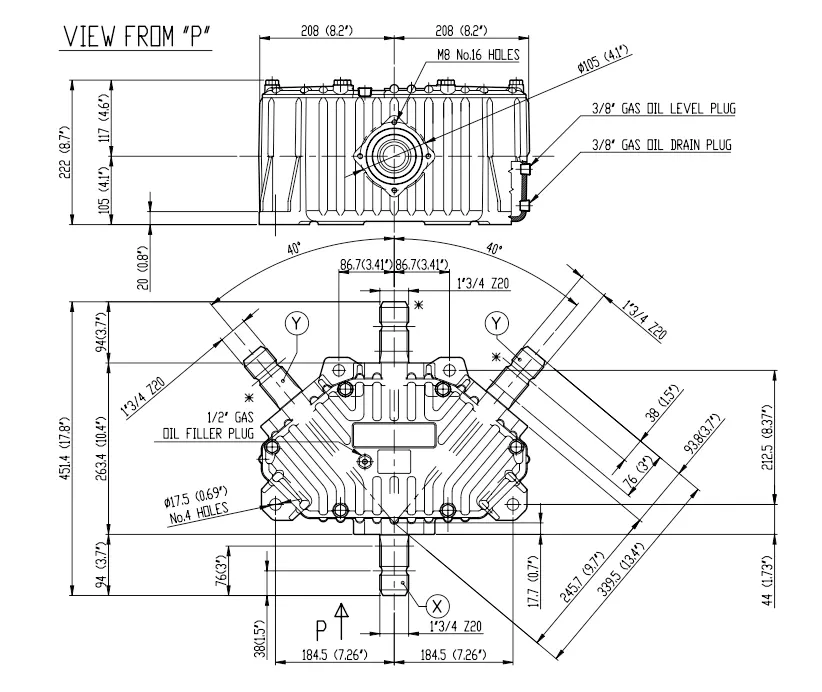

Specifications of Rotary Mower Gearbox T-305J

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type | Input | ||

| X | Y | Z | |||||

| 1.35 | 540 | 183.8 | 2335 | ” 3/4 Z20 | 1” 3/4 Z20 | ” 3/4 Z20 | X |

| 1.20 | 1000 | 183.8 | 2043 | ” 3/4 Z20 | ” 3/4 Z20 | ” 3/4 Z20 | X |

| 1.35 | 1000 | 183.8 | 2298 | ” 3/4 Z20 | ” 3/4 Z20 | ” 3/4 Z20 | X |

Features of Rotary Mower Gearbox

1. Efficient Power Transmission

The gearbox plays a central role in transferring power from the tractor’s engine to the mower blades. This efficient transmission ensures that the blades rotate at the optimal speed and torque, allowing the mower to cut grass and other vegetation smoothly. The gearbox’s ability to maintain consistent power transfer ensures efficient mowing even under tough conditions, such as dense grass or uneven terrain.

2. Durability and Longevity

Rotary mower gearboxes are engineered to withstand heavy-duty use and harsh conditions. Made from high-quality materials like cast iron, steel, or aluminum alloys, they offer resistance to wear, corrosion, and fatigue. This robust construction helps the gearbox perform effectively over extended periods, reducing the need for frequent repairs or replacements and making it suitable for long-term, reliable use.

3. Reduced Maintenance Requirements

Thanks to their durable design and efficient internal components, rotary mower gearboxes require less maintenance compared to other mower drives. The use of quality materials and lubrication helps minimize friction and wear, which ultimately reduces the frequency of repairs and replacements. This results in lower operating costs and more uptime for the mower, making it a more economical option for both small-scale and large-scale operations.

4. Improved Cutting Performance

The precision-engineered gearbox ensures that the mower blades operate at the right speed and torque, providing a clean, even cut every time. Whether it’s grass, weeds, or small brush, the gearbox allows the mower to handle thick vegetation and uneven ground more effectively. This consistent cutting performance is especially beneficial for landscaping and agricultural work where high-quality results are a priority.

5. Versatility and Customization

Rotary mower gearboxes come in a variety of configurations, such as single-speed or multi-speed models, to suit different applications. Many manufacturers, including FMP, offer customization options, allowing the gearbox to be tailored for specific tasks, such as adjusting the cutting height or providing additional torque for challenging mowing conditions. This flexibility makes the gearbox suitable for a wide range of industries, from agriculture to municipal landscaping.

The rotary mower gearbox is an essential component that greatly enhances the performance, reliability, and cost-effectiveness of mowing equipment. By efficiently transferring power, reducing maintenance requirements, and improving cutting performance, these gearboxes ensure optimal operation in agricultural, industrial, and landscaping applications. Whether used for routine lawn care or demanding agricultural tasks, a high-quality rotary mower gearbox is crucial for ensuring smooth and efficient mower operation.

About FMP

FMP, based in Italy, is a leading innovator in the design, development, and manufacturing of high-quality gearboxes, reducers, and engineering machinery. With a strong focus on talent development, continuous innovation, and delivering excellence, FMP has established itself as a prominent name in the mechanical engineering industry, gaining recognition both locally and globally.

Extensive Product Range

FMP offers a diverse portfolio of precision-engineered products, including:

- Spiral Bevel Gearboxes

- Spur Gearboxes

- Worm Gearboxes

- Cylindrical Gearboxes

- High-Pressure Cast Valve Bodies and Housings

Each of these products is meticulously designed to meet the highest standards of performance and reliability across a wide range of industrial applications.

Wide Applications Across Industries

FMP’s products serve various industries, offering versatile solutions for both industrial and agricultural needs. Key applications include:

- Agriculture: FMP gearboxes are used in machinery like rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors.

- Industrial Equipment: FMP’s gearboxes and components also support machinery in sectors such as oil extraction, marine applications, and hydraulic engineering projects.

This broad range of applications demonstrates FMP’s ability to provide tailored solutions that improve efficiency and productivity across different sectors.

Advanced Manufacturing Capabilities

FMP’s manufacturing process integrates cutting-edge technology and precise craftsmanship. Every product is built through a series of rigorous steps:

- Product Design: Custom specifications are developed, including the selection of gearbox types, materials, and dimensions.

- Material Selection: FMP utilizes high-grade materials like cast iron and aluminum alloys to ensure durability and optimal performance.

- Precision Machining: State-of-the-art techniques such as turning and milling are used to fabricate components with high accuracy.

- Assembly: Components such as gears, bearings, and shafts are meticulously assembled into the housing to ensure proper alignment and lubrication.

- Heat Treatment: The gearboxes undergo heat treatment to enhance strength and wear resistance, ensuring long-lasting durability.

- Surface Treatment: Processes like polishing and powder coating are employed to improve the aesthetics and corrosion resistance of the gearboxes.

- Quality Control: FMP adheres to strict quality control standards, conducting thorough inspections and testing to guarantee each product meets the required performance benchmarks.

Industry Reputation

FMP’s commitment to quality, innovation, and customer satisfaction has earned it a solid reputation as a trusted partner in the manufacturing industry. The company’s approach combines advanced technology with skilled craftsmanship to deliver long-term value to its clients. FMP continues to push the boundaries of innovation while maintaining its focus on reliability and excellence.

Partner with Us

FMP is always open to collaboration opportunities with global clients and partners. Whether you’re looking for high-quality products or customized solutions, we are committed to providing the expertise and service needed to meet your specific requirements. For more information or to explore potential partnerships, please contact us via phone or email. We look forward to working with you to deliver high-performance solutions tailored to your needs.

Author: CX