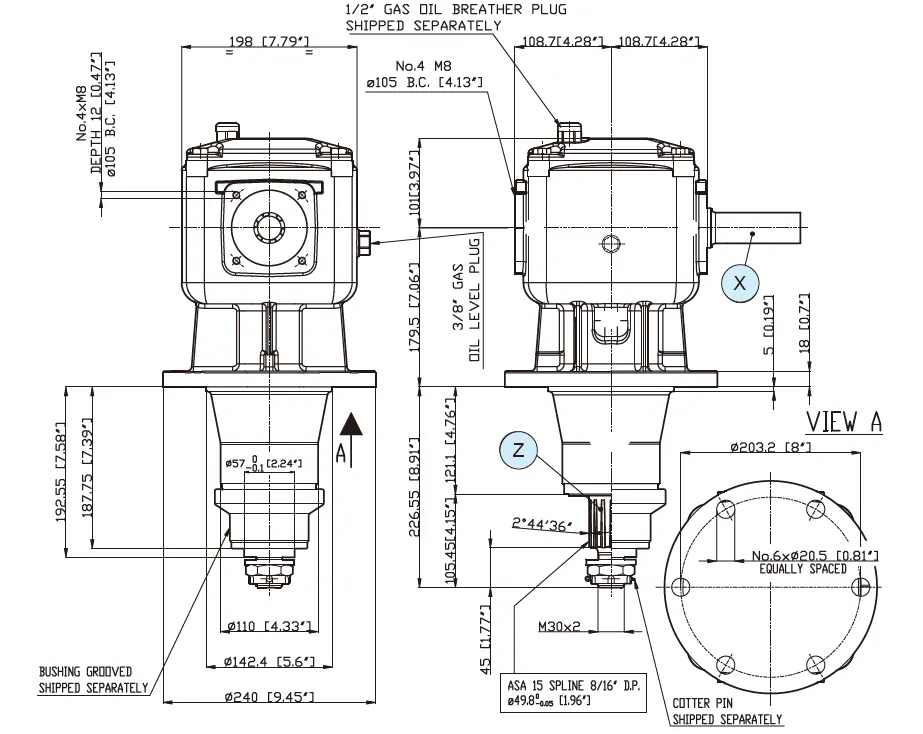

Specification of Rotary Mower Gearbox LF-227J

| Product | Rotary Mowers Gearboxes – Replacement of Comer Gearbox LF-227J |

| Application | Mowers |

| Technical information |

|

| Max. input power | 55 kW |

| Contains oil | No |

| Max. oil capacity | 0,8 l |

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade | 80W-90 |

| Housing material |

Cast iron GGG40

|

| Weight | 37 kg |

| Gear arrangement Increasing | 3 |

| Gear ratio | 1: 1.83 |

| Input power kW / HP Increasing | 55 / 75 kW/HP |

| Input shaft Increasing | X |

| Output Torque DaNm Increasing | 51.7 daNm |

| Ratio Increasing |

1: 1.83

|

| Ratio Reducing |

1.83: 1

|

| Shaft X |

1 3/8″ (6)

|

| Shaft Z |

ASA Z15 D.P. 8/16

|

Parts of LF-227J Rotary Mower Gearbox

|

|

Agricultural PTO Shaft for Rotary Mower Gearbox

The agricultural PTO (Power Take-Off) shaft plays a vital role in transferring power from a tractor’s engine to the rotary mower gearbox. This connection enables the mower blades to rotate and effectively cut grass, making it an essential component in large-scale land maintenance. A properly selected and maintained PTO shaft ensures the gearbox operates efficiently, helping to extend its lifespan and improve overall performance.

The PTO shaft connects to the tractor’s PTO and transmits power to the rotary mower. This allows the tractor’s engine to drive the mower gearbox, which in turn powers the blades. The PTO shaft’s main purpose is to facilitate the transfer of energy, enabling the mower to operate at full capacity and efficiently tackle mowing tasks.

Functionally, the PTO shaft consists of a splined end that attaches to the tractor’s PTO, and a yoke on the other end that connects to the mower’s gearbox. As the tractor engine rotates, it drives the PTO shaft, which turns the gearbox and powers the mower blades. This seamless transfer of power is essential for smooth, continuous mowing, especially for larger areas of land.

There are different types of PTO shafts available, each designed for specific applications. The 540 RPM PTO shaft is typically used for smaller, lighter implements, while the 1000 RPM PTO shaft is more suited for larger, more powerful machinery. Additionally, the dual-speed PTO shaft offers flexibility, allowing it to operate at both 540 and 1000 RPM speeds, depending on the needs of the equipment.

To ensure the longevity and efficiency of the PTO shaft, regular maintenance is crucial. Proper lubrication of the yoke ends and couplers helps reduce wear and tear, while keeping the shaft clean and free of debris prevents damage caused by dirt and corrosion. Routine inspections for signs of wear or damage are also important, as timely replacements of any worn parts can prevent costly repairs. By following these maintenance steps, the PTO shaft can perform optimally, contributing to the overall reliability of the rotary mower gearbox.

About FMP

About FMP

FMP, located in Italy, is a recognized leader in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. With a steadfast commitment to innovation, quality, and talent development, FMP has earned its place as a significant player in the mechanical engineering industry. The company’s continuous drive for excellence has helped it establish a strong reputation in both domestic and international markets, making it a trusted name in the field.

FMP offers a wide variety of high-performance products designed to meet the diverse needs of various industries. Its product portfolio includes spiral bevel gearboxes, spur gearboxes, worm gearboxes, cylindrical gearboxes, and high-pressure cast valve bodies and housings. Each product is meticulously engineered to deliver reliable and efficient performance, ensuring optimal results across heavy-duty industrial applications as well as more specialized uses.

The versatility of FMP’s products allows them to serve a broad range of industries. In agriculture, their gearboxes power essential machinery such as rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. Beyond agriculture, FMP also provides components for industrial machinery used in oil extraction, marine applications, and hydraulic engineering. This wide-ranging application showcases the adaptability and reliability of FMP’s products in diverse fields.

FMP’s advanced manufacturing processes reflect its dedication to quality. From design to final assembly, each product undergoes rigorous attention to detail. Only high-grade materials, including cast iron and aluminum alloys, are selected to ensure durability. Advanced machining techniques, such as turning and milling, are used to precisely fabricate components. The assembly process ensures proper alignment and lubrication for smooth operation, while heat treatments and surface coatings enhance strength, wear resistance, and appearance. Stringent quality control procedures guarantee that every product meets the highest performance standards.

FMP’s commitment to delivering superior products and exceptional service has earned it a stellar reputation in the manufacturing industry. By focusing on craftsmanship and customer satisfaction, the company continues to grow and strengthen its position in the market. FMP actively welcomes global partnerships, offering tailored solutions to meet the unique needs of clients worldwide. Prospective partners can easily reach out to FMP for more information, reaffirming the company’s dedication to excellence and customer-driven solutions.

Author: CX