Specifications of Rotary Mower Gearbox LF-140J

| Product Description |

Rotary Mower Gearbox – Replacement of Comer Gearbox LF-140J

|

|---|---|

| Product details |

|

| Application range |

Mowers

|

| Consists of |

|

| Contains oil |

No

|

| Max. oil capacity |

1.4 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

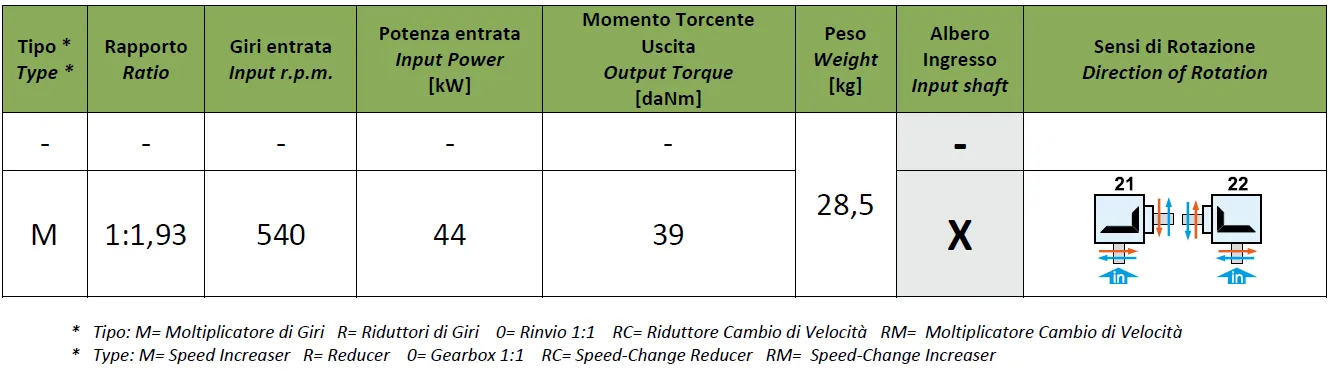

| Weight |

28.5 kg

|

| Gear arrangement Increasing |

3

|

| Input power kW / HP Increasing |

44 / 60 kW/HP

|

| Input shaft Increasing |

X

|

| Output Torque DaNm Increasing |

39 daNm

|

| Ratio Increasing |

1:1.93

|

| Ratio Reducing |

1.93: 1

|

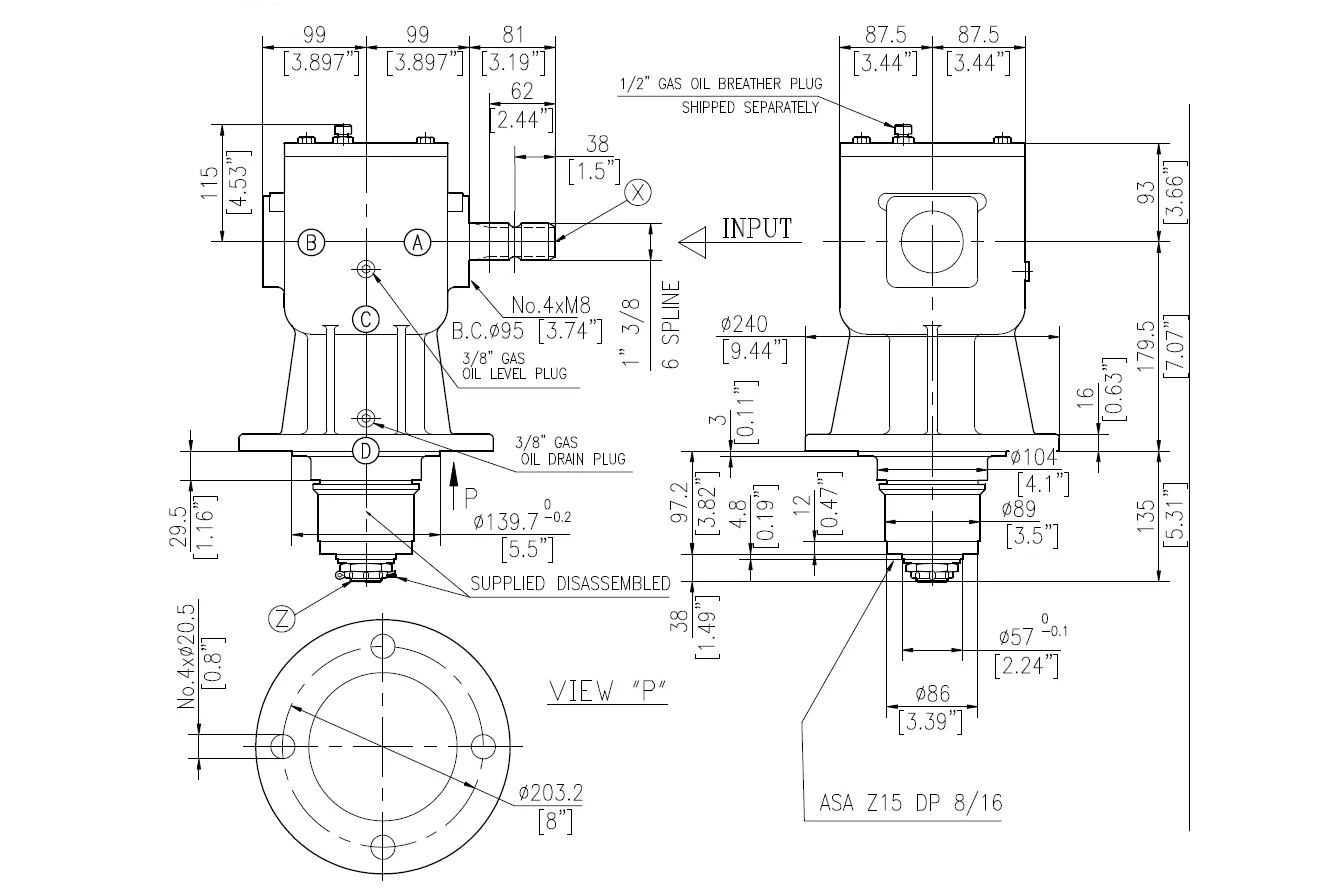

| Shaft X |

1 3/8″ (6)

|

| Shaft Z |

ASA Z15 D.P. 8/16

|

LF-140J Rotary Mower Gearbox Parts

The LF-140J rotary mower gearbox is a sophisticated piece of machinery, designed to provide reliable power transmission for rotary mowers. It is composed of several key components that work together to ensure efficient operation. Below is an overview of the essential parts that make up the LF-140J rotary mower gearbox:

- Input Shaft

The input shaft is the component that receives power from the tractor’s PTO shaft and transfers it to the internal gears of the rotary mower gearbox. It plays a critical role in initiating the power transfer to the gearbox. - Gears

The gears inside the gearbox are responsible for transmitting power from the input shaft to the output shaft. The design and configuration of the gears, including their size and the number of teeth, can vary based on the gearbox’s intended application and desired performance. - Bearings

Bearings are essential for supporting the shafts and gears within the gearbox. They allow these components to rotate smoothly with minimal friction, ensuring efficient operation and extending the lifespan of the gearbox. - Seals

Seals are used to prevent oil leakage and to protect the gearbox’s internal components from dirt, dust, and other contaminants. They help maintain the gearbox’s internal pressure and lubrication, contributing to long-term reliability. - Output Shaft

The output shaft is responsible for transmitting the power from the rotary mower gearbox to the mower blades or wheels. This shaft ensures that the mower blades rotate at the correct speed for efficient cutting. - Housing

The housing serves as the protective casing that holds all the internal components of the gearbox. It ensures that the gears, shafts, bearings, and seals are securely enclosed and protected from external elements, enhancing the durability of the gearbox. - Oil Level Plug

The oil level plug allows for monitoring and maintaining the proper oil level inside the gearbox. Regularly checking and adding oil as needed ensures that the gears and bearings are adequately lubricated, preventing wear and damage.

Understanding the various components of the LF-140J rotary mower gearbox is vital for its proper maintenance and operation. Regular inspection of these parts, along with following safety protocols and the manufacturer’s guidelines, can help extend the lifespan of the gearbox and ensure optimal performance.

Advantages of the LF-140J Rotary Mower Gearbox

The LF-140J rotary mower gearbox is an excellent choice for agricultural and industrial applications, offering a range of benefits that enhance its performance and reliability. Here are the key advantages of the LF-140J rotary mower gearbox:

- Efficient Power Transmission

Designed for optimal efficiency, the LF-140J gearbox effectively converts engine power, ensuring smooth and consistent power transfer to the mower blades. This enhances the overall performance and efficiency of the rotary mower. - Durable Construction

Built with high-quality materials, the LF-140J gearbox is engineered to withstand the tough conditions typical in agricultural and industrial environments. Its durable design ensures long-lasting performance even under heavy use. - Low Maintenance Requirements

The LF-140J gearbox is designed to be low-maintenance, reducing the need for frequent repairs and service. This saves time and maintenance costs while increasing operational uptime. - High Gear Ratio

With a gear ratio of 1:1.93, the LF-140J gearbox delivers increased torque and power to the mower, allowing it to handle more demanding tasks and ensuring efficient cutting performance, even in tough conditions. - Easy Installation

The LF-140J is designed for easy installation, making it a convenient choice for quick setup on rotary mowers. Its user-friendly design allows for minimal downtime and no need for complicated modifications during installation. - Versatility

The LF-140J gearbox is compatible with a wide range of rotary mowers, making it a versatile solution for various applications. Its flexibility allows it to be used across different types of equipment, offering a reliable and adaptable power transmission solution.

The LF-140J rotary mower gearbox is an ideal choice for those seeking a reliable, durable, and efficient gearbox for agricultural and industrial use. With its high power efficiency, robust construction, and easy maintenance, it delivers superior performance and versatility, making it an essential component for any rotary mower.

Agricultural PTO Shaft and Rotary Mower Gearbox

The Power Take-Off (PTO) shaft is an essential component in agricultural machinery, particularly in tractors. It serves as a critical link between the tractor’s engine and various attached implements, including rotary mowers. The PTO shaft transfers power from the tractor’s engine, transmitting rotational energy at high speeds to operate other equipment via a driveline that includes the rotary mower gearbox.

The rotary mower gearbox plays a vital role in the mower’s operation. It receives the high-speed rotational energy from the PTO shaft and converts it into lower-speed, high-torque motion, which is necessary for driving the mower blades. Mounted on the mower deck, the gearbox is powered by the PTO shaft extending from the tractor, and the power is transmitted through the gearbox and drive shaft to the mower blades, enabling efficient cutting.

To ensure optimal performance and prolong the lifespan of the mower, proper maintenance of both the PTO shaft and rotary mower gearbox is essential. Regular maintenance tasks such as lubricating the PTO shaft, checking the gearbox oil level, and inspecting for wear and damage can prevent breakdowns, reduce repair costs, and improve the efficiency of the equipment.

In summary, the PTO shaft and rotary mower gearbox are integral to the operation of rotary mowers in agricultural settings. Regular maintenance of these components is crucial for ensuring reliable performance, minimizing downtime, and extending the service life of the machinery.

About FMP

FMP, based in Italy, is a renowned company specializing in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. With a strong commitment to nurturing talent and fostering innovation, FMP has become a leader in its field.

Diverse Product Portfolio

The company’s product range includes:

- Spiral Bevel Gearboxes

- Spur Gearboxes

- Worm Gearboxes

- Cylindrical Gearboxes

- High-Pressure Cast Valve Bodies and Housings

Wide-Ranging Applications

FMP products are highly versatile and serve numerous industries, including:

- Agriculture: Used in rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors.

- Industrial Equipment: Supporting machinery for oil extraction, marine applications, and hydraulic components for engineering projects.

Advanced Manufacturing Processes

FMP takes pride in its robust technical and R&D capabilities, producing reliable, high-quality products through a meticulous production process:

- Product Design: Custom specifications are developed, including gearbox type, material, and dimensions.

- Material Preparation: High-grade materials such as cast iron and aluminum alloys are selected and prepared.

- Precision Machining: Components like gear shafts and housings are machined with advanced techniques such as turning and milling.

- Assembly: Gears, bearings, and shafts are assembled into the housing, ensuring precise alignment and proper lubrication.

- Heat Treatment: Gearboxes undergo heat treatment to enhance strength and wear resistance.

- Surface Treatment: Processes such as polishing and powder coating improve appearance and corrosion resistance.

- Quality Control: Rigorous inspections and testing ensure stability, accuracy, and compliance with performance standards.

Industry Reputation

FMP’s dedication to quality, innovation, and customer satisfaction has earned it a stellar reputation in the manufacturing sector. The company adheres to a philosophy centered on craftsmanship, advanced technology, and delivering lasting value.

Partner with Us

FMP welcomes collaboration opportunities with global clients and partners. For inquiries about our products and services, please contact us via phone or email. We are committed to delivering tailored solutions that meet your needs.

Author: CX