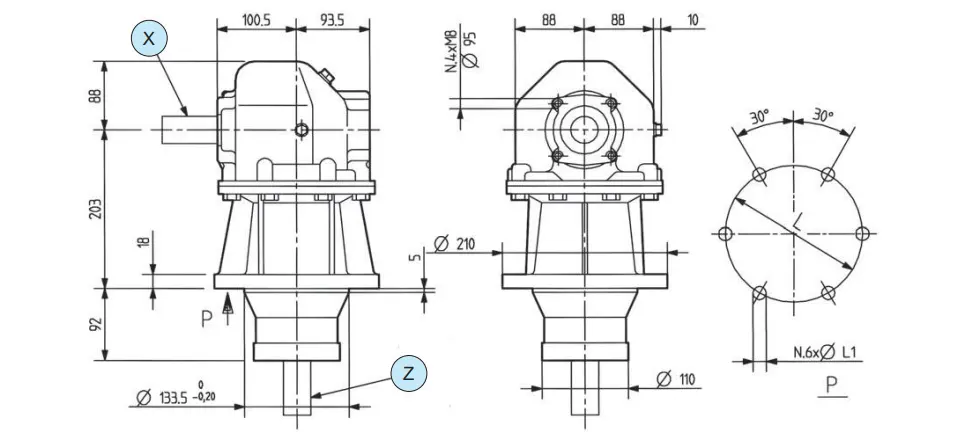

Specifications of Rotary Mower Gearbox LF-32J

| i | 1.93 |

| N1[rpm] | 540 |

| P1[kW] | 44.1 |

| M2[Nm] | 393 |

| Shaft Type X | 1” 3/8 Z6 |

| Shaft Type Z | Hub connection |

| Input | X |

PTO Shafts for Rotary Mower Gearboxes

When choosing a PTO (Power Take-Off) shaft for a rotary mower gearbox, it’s crucial to select the correct specifications to ensure optimal performance and safety. The PTO shaft serves as the link between the tractor’s engine and the gearbox, transmitting the power needed to operate the mower blades efficiently.

Key Considerations for Selecting the Right PTO Shaft

- Correct Length and Diameter: The length of the PTO shaft should be measured carefully to match your specific application. Measure from the center of the PTO spline on the tractor to the center of the input spline on the gearbox. Ensuring the right length is vital for proper alignment, preventing excessive stress on the driveline and allowing for smooth power transmission. The diameter of the PTO shaft is typically determined by the horsepower of the tractor and the size of the gearbox. A shaft that is too small for the required power may result in overheating or breakage, while a shaft that is too large could lead to inefficient operation.

- Horsepower and Torque Ratings: Selecting a PTO shaft with the correct horsepower and torque rating is essential for the safe and efficient operation of the rotary mower gearbox. Each gearbox has specific torque and horsepower requirements, which can usually be found in the manufacturer’s specifications. It’s essential to match the PTO shaft’s ratings to these requirements to avoid overloading the gearbox or the PTO shaft itself.

- Compatibility with Equipment: It is important to ensure that the PTO shaft is compatible with both the tractor and the rotary mower gearbox. PTO shafts are available in various sizes, including different spline types and configurations. Ensure the PTO shaft matches the spline type on both the tractor’s PTO output and the gearbox’s input shaft.

- Safety Features: Many PTO shafts are equipped with safety features, such as a shear pin or slip clutch, designed to protect both the equipment and the operator in the event of an overload or blockage. These features help prevent costly damage to the gearbox or other parts of the machinery, and they enhance safety during operation. Always choose a PTO shaft with these safety features to reduce the risk of accidents or equipment failure.

Regular Maintenance for Longevity and Efficiency

To ensure the longevity and optimal performance of your PTO shaft, regular maintenance is necessary. This includes:

- Lubrication: Ensure that the PTO shaft and its fittings are properly lubricated. Regular lubrication minimizes friction, which reduces wear and tear on the components, helping to extend their lifespan.

- Inspection for Wear and Damage: Periodically inspect the PTO shaft for signs of wear, such as bent shafts, damaged splines, or excessive play. Any damaged components should be replaced immediately to prevent further damage to the equipment or dangerous malfunctions during operation.

- Proper Storage: When not in use, store the PTO shaft in a dry, clean place to protect it from the elements. This helps prevent rust or corrosion from forming, which can hinder the shaft’s function and longevity.

By selecting the appropriate PTO shaft and maintaining it properly, you can ensure efficient power transfer, extend the life of both the PTO shaft and the rotary mower gearbox, and improve the overall performance and safety of your equipment.

PTO Shafts and Rotary Mower Gearboxes – Available for Purchase

We offer high-quality PTO shafts designed to fit a wide range of rotary mower gearboxes. Our PTO shafts are built to meet the rigorous demands of agricultural and industrial applications. Whether you’re replacing an existing PTO shaft or outfitting new equipment, we provide reliable, durable solutions. Contact us for more information on our PTO shaft offerings or to place an order.

About FMP

FMP, based in Italy, is a renowned company specializing in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. With a strong commitment to nurturing talent and fostering innovation, FMP has become a leader in its field.

Diverse Product Portfolio

The company’s product range includes:

- Spiral Bevel Gearboxes

- Spur Gearboxes

- Worm Gearboxes

- Cylindrical Gearboxes

- High-Pressure Cast Valve Bodies and Housings

Wide-Ranging Applications

FMP products are highly versatile and serve numerous industries, including:

- Agriculture: Used in rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors.

- Industrial Equipment: Supporting machinery for oil extraction, marine applications, and hydraulic components for engineering projects.

Advanced Manufacturing Processes

FMP takes pride in its robust technical and R&D capabilities, producing reliable, high-quality products through a meticulous production process:

- Product Design: Custom specifications are developed, including gearbox type, material, and dimensions.

- Material Preparation: High-grade materials such as cast iron and aluminum alloys are selected and prepared.

- Precision Machining: Components like gear shafts and housings are machined with advanced techniques such as turning and milling.

- Assembly: Gears, bearings, and shafts are assembled into the housing, ensuring precise alignment and proper lubrication.

- Heat Treatment: Gearboxes undergo heat treatment to enhance strength and wear resistance.

- Surface Treatment: Processes such as polishing and powder coating improve appearance and corrosion resistance.

- Quality Control: Rigorous inspections and testing ensure stability, accuracy, and compliance with performance standards.

Industry Reputation

FMP’s dedication to quality, innovation, and customer satisfaction has earned it a stellar reputation in the manufacturing sector. The company adheres to a philosophy centered on craftsmanship, advanced technology, and delivering lasting value.

Partner with Us

FMP welcomes collaboration opportunities with global clients and partners. For inquiries about our products and services, please contact us via phone or email. We are committed to delivering tailored solutions that meet your needs.

Author: CX