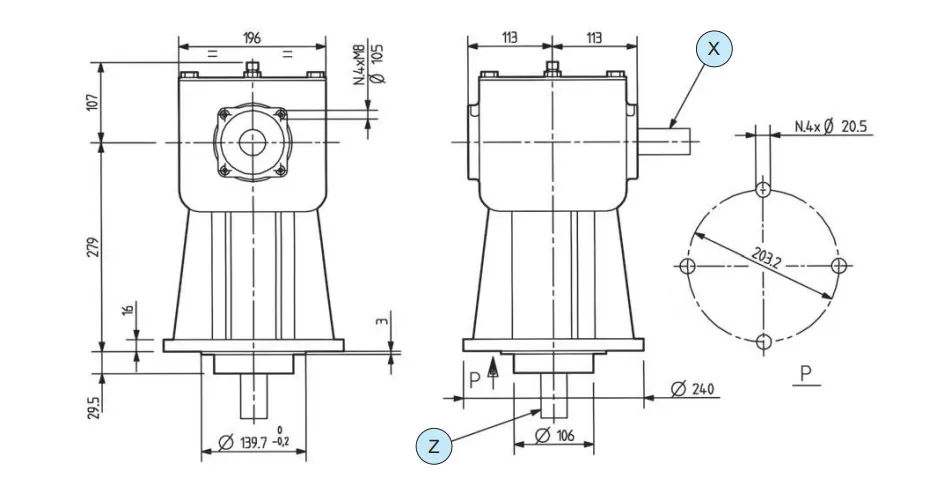

Rotary Mower Gearbox LF-139A Specifications

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type | Input | |

| X | Z | |||||

| 1.50 | 540 | 66 | 755 | 1” 3/8 Z6

1” 3/4 Z20 |

Hub connection | X |

| 1.20 | 1000 | 66 | 509 | 1” 3/4 Z20 | Hub connection | X |

Rotary Mower Gearbox Inspection and Maintenance

- Oil Level Check (For Gearboxes with Oil Level Plugs) It is essential to regularly check the oil level in the rotary mower gearbox to ensure optimal lubrication. Begin by verifying that the oil level is correct and that the oil quality is satisfactory. If the oil level is low, it should be topped up with the recommended oil type. After the inspection, securely reinstall the oil level plug to prevent any leakage or contamination.

- Oil Replacement Replacing the oil in the gearbox is critical for maintaining proper functionality and prolonging its lifespan. Always perform the oil change when the gearbox is at operating temperature to ensure complete drainage. Before beginning the replacement, make sure to cut off the power supply to avoid the risk of electric shock. Once the gearbox has cooled down and is safe to handle, the oil viscosity increases, making it harder to drain. Therefore, allow the gearbox to cool fully before removing the drain plug and replacing the oil. Use the manufacturer’s recommended oil type for optimal performance.

- Oil Level Inspection To check the oil level in the gearbox, first ensure the power is disconnected to prevent electric shock. Wait for the mower gearbox to cool down, and then remove the oil level plug to inspect the oil level. If the oil is low, top it up according to the manufacturer’s guidelines. Once the oil level is corrected, securely close the oil level plug to ensure no leakage occurs during operation.

- Oil Quality Inspection Regular inspection of the oil quality is vital to detect any signs of contamination or degradation. After cutting off the power and allowing the gearbox to cool, remove the oil drain plug and collect a sample of the oil. Check for any discoloration, turbidity, or the presence of particles. If the oil appears cloudy or shows signs of excessive wear, it is crucial to replace it immediately to prevent damage to the gearbox. Monitoring the viscosity index and other oil properties ensures smooth operation and minimizes the risk of gearbox failure.

PTO Shafts and Rotary Mower Gearboxes

When selecting a PTO (Power Take-Off) shaft for use with a rotary mower gearbox, several key factors must be considered to ensure proper operation and longevity. First, confirm that the PTO shaft length is appropriate for the specific setup. Measure the length from the center of the PTO spline on the tractor to the center of the input spline on the gearbox to ensure proper alignment.

The diameter of the PTO shaft should match the tractor’s horsepower and the gearbox’s torque requirements. This information can typically be found in the manufacturer’s specifications, which guide you to select the correct shaft size. Using an incorrectly sized PTO shaft can lead to inefficient operation, excessive wear, and even mechanical failure.

Beyond selecting the right size, it’s important to regularly inspect the PTO shaft for signs of wear, damage, or misalignment. Check for any cracks, bending, or excessive lubrication loss, and ensure the connections are securely fastened. Regular maintenance helps prevent downtime and ensures the safe and efficient operation of both the PTO shaft and the rotary mower gearbox.

FMP offers a range of rotary mower gearboxes and PTO shafts, including the LF 139A model, along with many other high-performance products designed for agricultural applications. Ensuring proper maintenance and selecting the right components will maximize the efficiency and lifespan of your equipment, making land maintenance easier and more cost-effective.

About FMP

FMP, based in Italy, is a leading company renowned for its expertise in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. With a commitment to innovation, quality, and the nurturing of talent, FMP has established itself as a key player in the mechanical engineering industry. The company’s dedication to continuous improvement and excellence has earned it a strong reputation in both domestic and international markets.

Comprehensive Product Portfolio

FMP offers a diverse range of high-performance products designed to meet the needs of various industries. Its product portfolio includes:

- Spiral Bevel Gearboxes

- Spur Gearboxes

- Worm Gearboxes

- Cylindrical Gearboxes

- High-Pressure Cast Valve Bodies and Housings

Each product is engineered with precision, ensuring reliable and efficient performance. Whether for heavy-duty industrial use or specialized applications, FMP’s gearboxes and components are built to deliver optimal results.

Wide Applications Across Industries

The versatility of FMP’s products makes them suitable for a wide range of industries. In the agricultural sector, their gearboxes power essential machinery such as rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. In addition to agriculture, FMP provides industrial machinery components for applications in oil extraction, marine systems, and hydraulic engineering projects. This broad scope of use demonstrates the adaptability and widespread appeal of FMP’s product offerings.

Advanced Manufacturing Excellence

FMP’s commitment to quality is evident in its advanced manufacturing processes. From the initial design phase to final assembly, each product is crafted with precision. The company uses only high-grade materials, such as cast iron and aluminum alloys, to ensure durability and performance. Advanced machining techniques, including turning and milling, are employed to fabricate each component with exacting standards. The assembly process focuses on ensuring proper alignment and lubrication for smooth operation, while heat treatment and surface coatings enhance strength, wear resistance, and appearance. Rigorous quality control procedures ensure that each product meets the highest performance standards for stability, reliability, and longevity.

Industry Reputation and Global Partnerships

FMP’s dedication to delivering superior products and exceptional customer service has earned it a stellar reputation in the manufacturing industry. The company’s focus on craftsmanship, innovation, and customer satisfaction drives its continued success. FMP welcomes global partnerships and is committed to providing customized solutions that meet the unique requirements of clients worldwide. For more information on its products and services, prospective partners can easily reach out to FMP via phone or email, reaffirming the company’s commitment to customer-driven excellence.

Author: CX