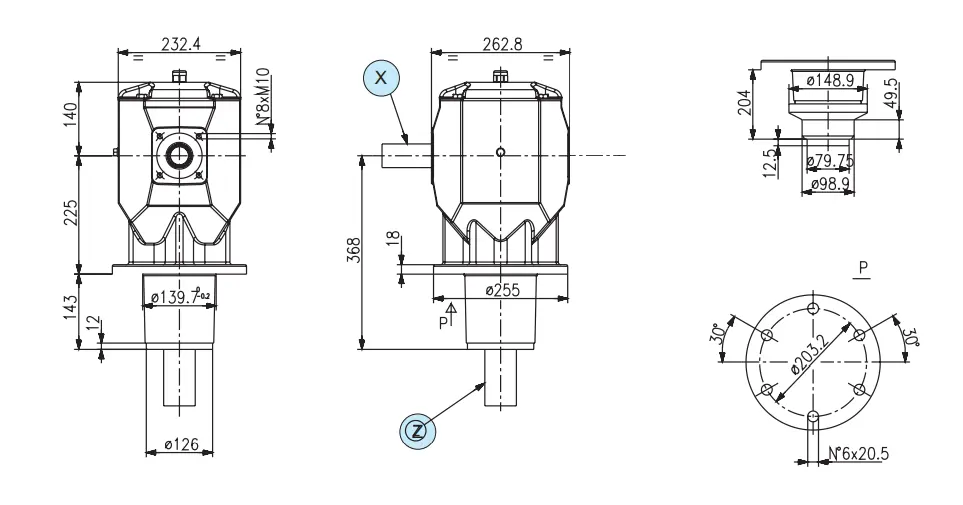

Rotary Mower Gearbox LF-125J Specifications

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type | Input | |

| X | Z | |||||

| 1.77 | 540 | 93.0 | 901 | 1” 3/4 Z20 | Hub connection | X |

| 1.00 | 1000 | 93.0 | 861 | 1” 3/4 Z20 | Hub connection | X |

- Power Transmission

The primary function of a rotary mower gearbox is to transmit power from the tractor’s PTO shaft to the mower blades. The gearbox converts the tractor’s engine power into the necessary torque and speed required for the blades to effectively cut through grass and vegetation. - Durable Construction

Rotary mower gearboxes are built with high-strength materials, such as cast iron or aluminum alloys, to withstand heavy loads and harsh operating conditions. The housing is typically rugged and reinforced to protect the internal components from damage during operation in demanding environments. - Hardened Gears

The gears within a rotary mower gearbox are often heat-treated and hardened to enhance their strength and resistance to wear. These gears ensure smooth power transfer and can handle the high torque required to drive the mower blades through thick grass, weeds, and other tough vegetation. - Sealed for Lubrication

Rotary mower gearboxes are equipped with oil seals that prevent lubricant from leaking out while keeping dirt, water, and debris from entering the gearbox. Proper lubrication is essential for reducing friction, preventing overheating, and extending the life of the gearbox. - Compact Design

These gearboxes are typically compact and designed to be lightweight, making them easy to install and maintain. Their space-efficient design allows for optimal power transfer while keeping the overall system weight manageable. - Adjustable Speed and Torque

Many rotary mower gearboxes feature the ability to adjust the speed and torque of the mower blades. This flexibility allows operators to fine-tune the performance of the mower according to the specific cutting requirements, whether it’s for grass, brush, or more challenging vegetation.

These features combined make the rotary mower gearbox a crucial part of the equipment that ensures reliable, efficient, and safe mowing performance, especially in demanding agricultural and landscaping applications.

PTO Shafts for Rotary Mower Gearbox

PTO (Power Take-Off) shafts are essential for transmitting power from the tractor’s engine to the rotary mower gearbox, enabling the mower blades to function. Here are the key factors to consider when selecting and using a PTO shaft for a rotary mower gearbox:

1. Length:

The length of the PTO shaft is a crucial consideration when selecting the right shaft for your rotary mower. It needs to match the distance between the tractor’s PTO output and the input shaft of the mower gearbox. If the PTO shaft is too long or short, it can cause inefficiency in power transfer or damage to the components. Ensure accurate measurements are taken to select the correct length.

2. Capacity:

PTO shafts come in different power capacities, typically rated in horsepower (HP). It is essential to choose a PTO shaft that matches the required power and torque needed by the rotary mower gearbox. The capacity should align with the tractor’s engine output and the mower gearbox specifications. Choosing a PTO shaft with inadequate capacity can result in excessive wear, mechanical failure, or damage to the equipment.

3. Safety:

Safety should always be a priority when working with PTO shafts. Before performing any maintenance, repairs, or adjustments on the rotary mower or gearbox, ensure that the tractor is turned off, and the PTO shaft is disconnected. PTO shafts rotate at high speeds and can cause serious injury if handled improperly. Always follow safety protocols and use appropriate protective gear to minimize risk.

4. Quality:

The quality of the PTO shaft directly affects its performance and durability. A high-quality PTO shaft is constructed using durable materials such as high-strength steel to withstand wear, corrosion, and regular mechanical stress. When selecting a PTO shaft, ensure that it is precision-engineered to ensure long-lasting, reliable performance in demanding agricultural conditions.

5. Compatibility:

It is vital to ensure that the PTO shaft is fully compatible with both the tractor and the rotary mower gearbox. Compatibility involves checking the spline size, the number of splines, and the connection type at both ends of the shaft. Using a mismatched PTO shaft can lead to inefficiencies, operational issues, or damage to both the PTO and gearbox components.

About FMP

FMP offers a comprehensive selection of PT O shafts suitable for various rotary mower gearboxes. Whether you need a standard PTO shaft or a custom solution, FMP provides high-quality products that ensure reliable performance. For further details or to place an order, contact us directly for expert assistance.

FMP, located in Italy, is a renowned leader in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. The company has gained recognition for its innovative approach, high-quality standards, and commitment to nurturing talent, positioning itself as a key player in the mechanical engineering sector. FMP’s focus on continuous improvement and excellence has contributed to its strong reputation both domestically and internationally.

The company offers a wide range of products, including spiral bevel gearboxes, spur gearboxes, worm gearboxes, cylindrical gearboxes, and high-pressure cast valve bodies and housings. These products are engineered with precision to ensure optimal performance and reliability in various industrial applications. FMP’s gearboxes and components are crafted to meet the specific demands of each client, delivering efficiency and durability in both heavy-duty industrial operations and specialized machinery.

FMP’s products serve a broad spectrum of industries. In agriculture, they are used in equipment like rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. Additionally, FMP’s gearboxes and components support machinery in oil extraction, marine systems, and hydraulic engineering, demonstrating their adaptability and versatile application across industries.

The company takes great pride in its advanced manufacturing capabilities. Each product undergoes a meticulous production process, starting with the design phase, where custom specifications are developed for each application. High-grade materials, such as cast iron and aluminum alloys, are selected for durability and performance. Precision machining techniques, including turning and milling, ensure the accuracy of every component, while the assembly process guarantees proper alignment and lubrication. Rigorous quality control procedures are in place to ensure the stability, reliability, and longevity of each product.

FMP’s dedication to quality, innovation, and customer satisfaction has solidified its position as a respected leader in the manufacturing industry. The company’s craftsmanship and use of advanced technology ensure the delivery of lasting value. FMP is always open to global partnerships and collaborations, offering customized solutions to meet the unique needs of clients worldwide. For further inquiries, potential partners can easily reach out via phone or email, reaffirming FMP’s commitment to delivering exceptional customer service and high-performance products.

Author: CX