Rotary Drilling Cylinder

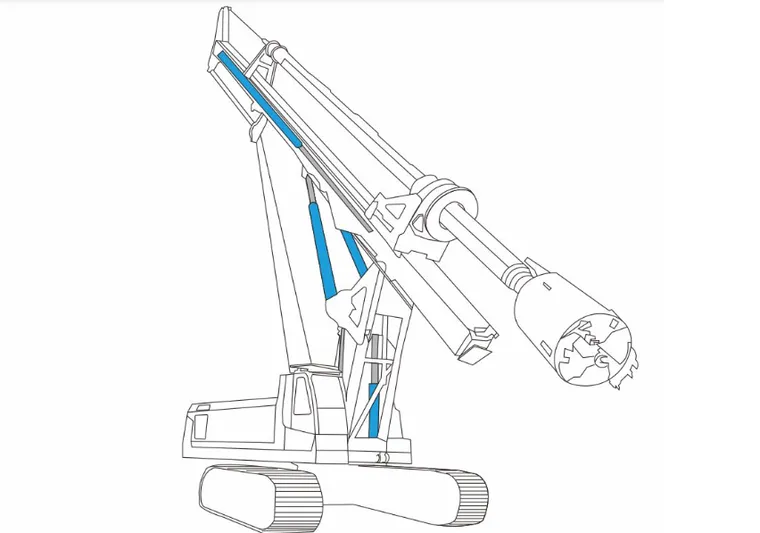

The Rotary Drilling Cylinder is a crucial hydraulic component designed to facilitate the rotary motion required for drilling operations in various applications, including construction, mining, and geotechnical engineering. This cylinder provides the necessary force to rotate the drill bit, enabling efficient penetration into different types of soil and rock.

Key Features:

- Robust Construction: Made from high-strength materials, the rotary drilling cylinder is engineered to endure the demanding conditions of drilling environments, ensuring long-lasting durability and reliability.

- Smooth Operation: The hydraulic design allows for smooth and controlled rotation, providing precise drilling capabilities and improving overall operational efficiency.

- Versatile Application: Suitable for a wide range of drilling equipment, this cylinder enhances the functionality of rotary drills, augers, and other drilling machinery, making it ideal for various projects.

- Enhanced Performance: By delivering consistent power and torque, the rotary drilling cylinder optimizes drilling performance, enabling faster and more effective penetration.

- Low Maintenance Requirements: Designed for minimal wear, this cylinder requires less maintenance, reducing downtime and contributing to increased productivity in drilling operations.

In summary, the Rotary Drilling Cylinder is an essential component that enhances the efficiency and effectiveness of drilling operations, making it indispensable for various industrial and construction applications.

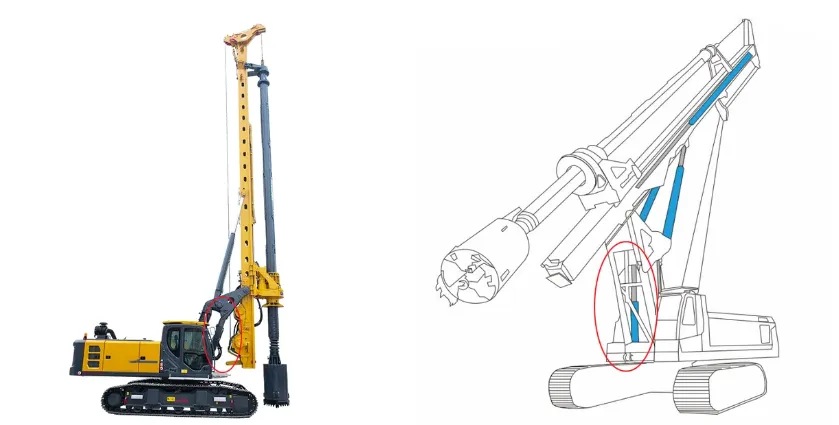

Rotary Drilling Luffing Cylinder Specifications:

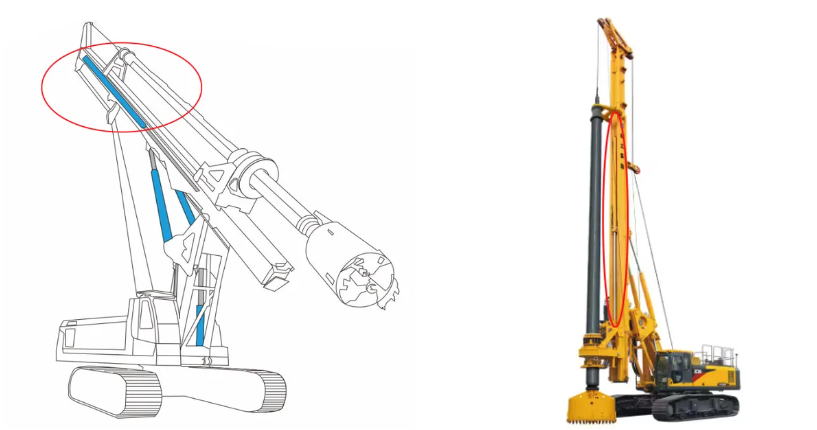

The Rotary Drilling Luffing Cylinder is a vital hydraulic component designed to control the angle of the drilling rig’s boom, allowing for precise positioning during drilling operations. This cylinder enables the luffing motion, which adjusts the boom’s height and angle to optimize drilling efficiency and access to various depths. Constructed from high-strength materials, it is built to withstand the demanding conditions of construction and drilling environments, ensuring durability and reliability. The smooth hydraulic operation of the luffing cylinder allows for quick adjustments, enhancing the rig’s versatility and performance while ensuring safe and efficient drilling across diverse applications.

| Product Name | Rotary Drilling Luffing Cylinder |

| Features: | Control the luffing angle, adjust the distance between the mast and the host |

| Bore diameter: | 125mm~250mm |

| Rod diameter: | 90mm~160mm Stroke≤1640 mm |

| Pressure: | up to 32MPa |

| Luffing Cylinder Applications: | Rotary Drilling |

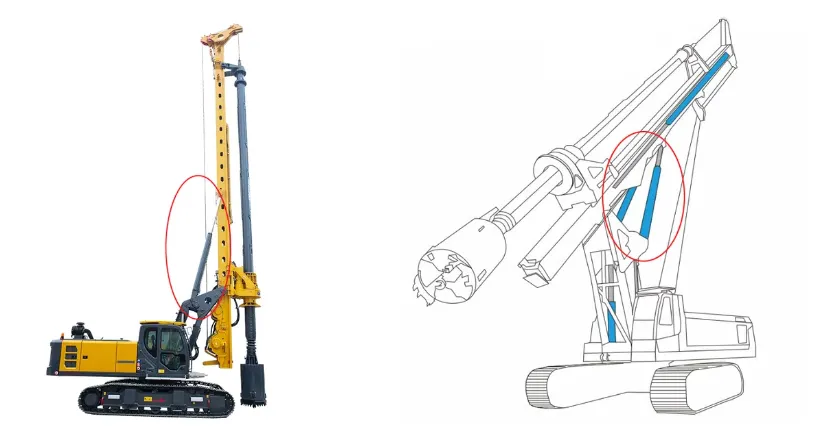

Rotary Drilling Mast Cylinder Specifications:

The Rotary Drilling Mast Cylinder is a crucial hydraulic component that supports the vertical movement of the drilling mast, enabling it to raise and lower during drilling operations. This cylinder is designed to provide the necessary force for extending the mast to various heights, allowing for efficient access to depths required for drilling. Constructed from high-strength materials, it is engineered to withstand the rigorous demands of drilling environments, ensuring long-lasting durability and reliability. The smooth hydraulic action of the mast cylinder facilitates precise control, enhancing the overall stability and performance of the drilling rig while ensuring safe and effective operations across a range of applications.

| Product Name | Rotary Drilling Mast Cylinder |

| Features: | Control the mast, adjust the angle of the mast and the ground |

| Bore diameter: | 140mm~350mm |

| Rod diameter: | 90mm~230mm Stroke≤5550mm |

| Pressure: | up to 32MPa |

| Mast Cylinder Applications: | Rotary Drilling |

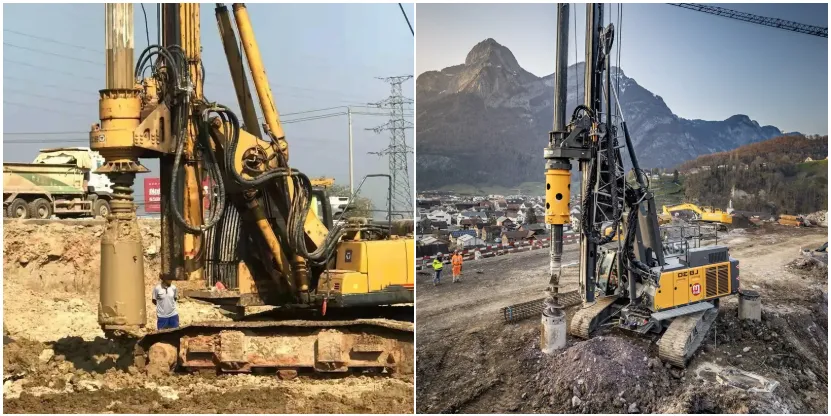

Rotary Drilling Pressurized Cylinder Specifications:

The Rotary Drilling Pressurized Cylinder is a critical hydraulic component designed to apply and maintain pressure during rotary drilling operations. This cylinder ensures that the drill bit receives consistent force, enhancing its effectiveness in penetrating various soil and rock formations. Constructed from high-strength materials, it is built to endure the demanding conditions of drilling environments, providing durability and reliability. The pressurized action allows for efficient drilling performance, improving the speed and effectiveness of operations. Additionally, the cylinder’s design facilitates smooth hydraulic movement, ensuring precise control and stability during drilling tasks, making it essential for various construction and geotechnical applications.

| Product Name | Rotary Drilling Pressurized Cylinder |

| Features: | Control the lifting and lowering of the power head |

| Bore diameter: | 125mm~210mm |

| Rod diameter: | 90mm~150mm Stroke≤8500mm |

| Pressure: | up to 35MPa |

| Pressurized Cylinder Applications: | Rotary Drilling |

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX