Rotary Cutter Gearboxes – Replacement of Omni Code RC-81 Gearbox

The Rotary Cutter Gearbox – Replacement of Omni Code RC-81 Gearbox is a high-performance, durable solution designed to replace the Omni Code RC-81 gearbox in rotary cutter systems. Built to handle heavy-duty agricultural and industrial tasks, this replacement gearbox ensures reliable power transmission, optimal cutting performance, and extended operational life for rotary cutters used in demanding environments such as mowing, land clearing, and vegetation control.

Key Features:

- Enhanced Power Capacity

This replacement gearbox is engineered to handle up to 80 horsepower, making it suitable for demanding applications such as land clearing, brush cutting, and large-scale mowing. Its robust design ensures that the gearbox can effectively transfer power from the PTO system to the rotary cutter blades, delivering consistent and efficient performance even under heavy load conditions. - Durable Construction for Harsh Environments

Designed with high-quality, heavy-duty materials, the RC-81 replacement gearbox offers exceptional durability and resistance to wear, corrosion, and environmental stress. Its rugged construction ensures that it can withstand continuous operation in harsh conditions, including exposure to dirt, moisture, and debris, providing long-lasting reliability in challenging agricultural and industrial settings. - Efficient Power Transmission

The gearbox is specifically designed for optimal power transmission with minimal energy loss. By efficiently transferring power from the PTO shaft to the rotary cutter blades, it maximizes cutting efficiency while reducing fuel consumption and operational costs. This feature makes the replacement gearbox a highly cost-effective solution, enabling operators to achieve superior cutting results with lower operational expenses.

The Rotary Cutter Gearbox – Replacement of Omni Code RC-81 Gearbox offers a high-performance, durable, and efficient solution for rotary cutter systems. With its enhanced power capacity, reliable power transmission, and easy installation, it ensures dependable performance in a wide range of agricultural and industrial applications. Designed to handle heavy-duty tasks like land clearing, brush cutting, and mowing, this replacement gearbox offers long-lasting reliability, minimal maintenance, and cost-effective operation for all types of rotary cutter operations.

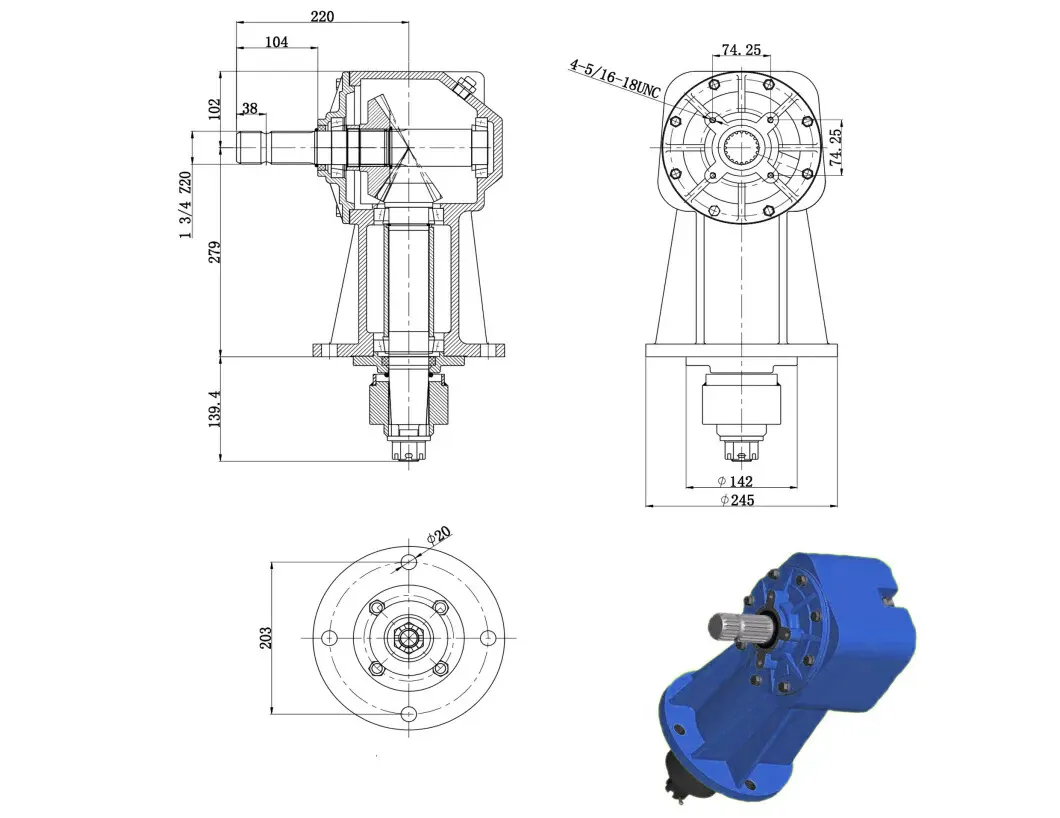

RC81 Rotary Cutter Gearbox Specifications

| Use | Part Number | Input Parameters | Output Parameters | |||||

| Ratio | Rotational Speed | Power | Horse Power | Torque | Torque | Rotational Speed | ||

| R.P.M | KW | HP-CV | N.M | N.M | R.P.M | |||

| Rotary Cutter | RC81-01 | 1:1.92 | 540 | 74 | 100 | 1308 | 680 | 1038 |

| RC81-02 | 1:1.46 | 540 | 74 | 100 | 1308 | 680 | 788 | |

| Model | FMP-RC-81 Rotary Cutter Gearbox |

| Torque | 5,483 – 12,133 lb.-in. (619 – 1,370 Nm.) |

| Ratios | 1.21:1, 1:1, 1:1.21, 1:1.46, 1:1.92 |

| Gear Type | Bevel |

| Seal Type | Triple Lip Spring Loaded |

| Bearing Type | Tapered Roller |

| Oil Capacity | 62 oz. (1.8 L) |

| Weight | 98 lbs. (44.5 kg.) |

How Does the Rotary Cutter Gearbox Work?

The rotary cutter gearbox is a crucial component in agricultural machinery, converting power from the tractor’s PTO system to the rotary cutter blades, enabling efficient cutting of grass, brush, and other vegetation. The gearbox plays an essential role in power transmission, ensuring the rotary cutter operates smoothly and reliably in tough working conditions.

Power Transfer from the PTO System

The process begins when the tractor’s Power Take-Off (PTO) system generates mechanical power. This power is transferred through the PTO shaft to the rotary cutter gearbox. The PTO shaft connects to the input shaft of the gearbox, transferring rotational power. The gearbox then converts this power into the necessary speed and torque required to turn the rotary cutter blades, ensuring they rotate at the optimal speed for cutting.

Gear Reduction for Optimal Blade Speed

Inside the gearbox, a series of gears are arranged to reduce the input RPM from the PTO shaft to a lower, more suitable RPM for the rotary cutter blades. This gear reduction system is essential because the cutting blades need to rotate at a specific speed to efficiently cut vegetation without overloading the tractor’s engine. The reduction gears inside the gearbox allow for a high torque output while maintaining the appropriate blade speed for different cutting tasks.

Torque Transmission to the Cutter Blades

The rotary cutter gearbox is designed to deliver the necessary torque to the cutting blades. After the input power is reduced to the right speed, the torque is transferred to the output shaft of the gearbox, which is connected to the blades. The gearbox ensures that enough rotational force is delivered to the blades to cut through thick grass, brush, and small shrubs. The output shaft often has a universal joint that connects to the blades, ensuring smooth rotational movement.

Durability Under Heavy Load

The rotary cutter gearbox is built to withstand high torque and heavy-duty applications. As the blades cut through dense vegetation, the gearbox absorbs the shock and pressure generated during operation. The heavy-duty construction of the gearbox ensures that it can handle these intense forces, preventing damage to internal components and ensuring the gearbox can last for long periods with minimal maintenance. The gearbox’s housing is designed to resist wear and tear, corrosion, and environmental damage, ensuring it continues to operate reliably in harsh conditions.

Safety and Maintenance Considerations

To ensure the gearbox operates safely, it is equipped with various safety features such as protective covers and shields to prevent debris from entering and damaging the internal gears. Regular maintenance is essential for keeping the gearbox in optimal condition, which typically involves checking and replenishing the lubricant, inspecting for any damage or wear, and ensuring all connections are secure. Proper maintenance ensures that the gearbox continues to work efficiently and safely, providing the necessary power for the rotary cutter blades to perform at their best.

The rotary cutter gearbox works by efficiently transferring mechanical power from the tractor’s PTO system to the cutting blades through a series of gears that reduce RPM and increase torque. This system ensures that the blades rotate at the optimal speed to cut through vegetation effectively. Built for durability, the gearbox can handle heavy loads and tough conditions, while safety features and regular maintenance ensure reliable performance over time. Whether used for mowing, land clearing, or vegetation management, the rotary cutter gearbox is a vital component for efficient cutting operations.

PTO Shaft and Rotary Cutter Gearbox for Rotary Cutter

The PTO shaft and rotary cutter gearbox are essential components of rotary cutter systems, working in tandem to provide the power and reliability needed for effective land management. The PTO shaft transfers mechanical power from the tractor’s PTO system to the gearbox, which then drives the cutting blades. Together, these components ensure smooth operation and optimal performance in a wide range of agricultural and industrial applications such as mowing, brush clearing, and vegetation management.

Efficient Power Transmission with PTO Shaft

The PTO shaft serves as the critical link between the tractor and the rotary cutter gearbox. It transmits the mechanical power from the tractor’s PTO system to the gearbox, which drives the rotary cutter’s blades. Designed for efficiency, the PTO shaft ensures minimal energy loss during power transfer, allowing for smooth, uninterrupted cutting performance. This efficient transmission of power contributes to reduced fuel consumption and increased productivity, making it an essential component for high-performance land management tasks.

Durable and High-Performance Rotary Cutter Gearbox

The rotary cutter gearbox is engineered to handle heavy-duty applications, converting the power transferred by the PTO shaft into the rotational energy needed to drive the cutting blades. These gearboxes are built to endure tough conditions, including constant exposure to debris, moisture, and dirt, making them highly durable and long-lasting. Their robust construction ensures that they can withstand high torque loads and heavy shock impacts, providing reliable performance even in the most demanding environments such as land clearing and road maintenance.

Safety Features for Operator Protection

Both the PTO shaft and rotary cutter gearbox are equipped with safety features to protect the operator during operation. The PTO shaft is designed with protective covers and shields that prevent accidental contact with rotating parts, reducing the risk of injury. The gearbox is also engineered to minimize vibrations, ensuring smoother operation and less strain on both the equipment and the operator. These safety features make the PTO shaft and gearbox combination safer to use, promoting a secure working environment.

Easy Installation and Maintenance

The PTO shaft and rotary cutter gearbox are designed for easy installation and integration with rotary cutter systems. The PTO shaft typically features a quick-connect mechanism that allows for fast attachment to the tractor’s PTO system. The gearbox is also designed for easy mounting to the rotary cutter frame, simplifying the installation process and minimizing downtime. Additionally, both components require minimal maintenance, with the gearbox featuring grease points for lubrication and the PTO shaft being easy to inspect and maintain. Regular maintenance ensures their longevity and continued high performance.

Versatile Applications for Agriculture and Industry

The PTO shaft and rotary cutter gearbox are versatile components that are used in a variety of applications. In agriculture, they are essential for tasks like mowing large fields, managing grass and brush, and maintaining pastures. For industrial applications, they are ideal for clearing land, managing roadside vegetation, and vegetation control on construction sites or utility corridors. Their ability to handle heavy loads and tough cutting conditions makes them invaluable for any operation requiring reliable and efficient rotary cutting performance.

The PTO shaft and rotary cutter gearbox work together to provide reliable, efficient, and durable performance in rotary cutter systems. Designed to handle the power transfer from the tractor to the cutting blades, they ensure optimal cutting efficiency and safety. Their easy installation, low maintenance, and versatility make them ideal for a wide range of agricultural, industrial, and land management applications, offering a cost-effective solution for demanding cutting tasks. Whether used for mowing, brush clearing, or vegetation management, these components are built to last and provide high performance in any environment.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer with a strong reputation for excellence in the design, development, and production of high-performance gearboxes, specializing in the agricultural machinery sector. Renowned for our precision engineering, innovative solutions, and unmatched reliability, FMP consistently delivers top-tier products that meet the evolving demands of both the agricultural and industrial markets. Our extensive product range includes advanced gearboxes for lawn mowers, PTO shafts, and other key components, all designed to provide tailored solutions for a wide variety of applications.

At FMP, we understand that each client has unique challenges and requirements. That’s why we offer customized solutions, whether it’s individual components or fully integrated systems. We collaborate closely with our customers to ensure that every solution not only addresses their specific needs but also enhances performance and maximizes value. Our commitment to fast, professional responses, paired with expert guidance, ensures that every inquiry is managed with precision and care.

We place great emphasis on clear, ongoing communication, particularly when developing new products. Our dedicated team works directly with clients to understand their specific needs, providing practical insights that lead to optimal, effective solutions. Whether we’re developing cutting-edge products or fulfilling ongoing orders, we remain committed to delivering high-quality, precision-engineered solutions that meet the highest standards of speed and reliability.

Quality is at the core of FMP’s operations. We adhere to stringent manufacturing standards and implement rigorous quality control procedures to ensure every product not only meets but exceeds industry expectations. Our unwavering commitment to quality, combined with our values of integrity, collaboration, and persistence, has enabled us to build long-term partnerships with clients across more than 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to providing expert advice and customized solutions that address the diverse needs of our clients. We go beyond simply supplying products—we strive to establish meaningful, long-lasting relationships that contribute to the success of every project. Whether you’re looking for innovative solutions for a new initiative or ongoing support for an existing system, FMP is committed to helping you overcome technical challenges and ensuring your continued success.

Author: CX