Rotary Cutter Gearboxes – Replacement of Omni Code RC-71 Gearbox

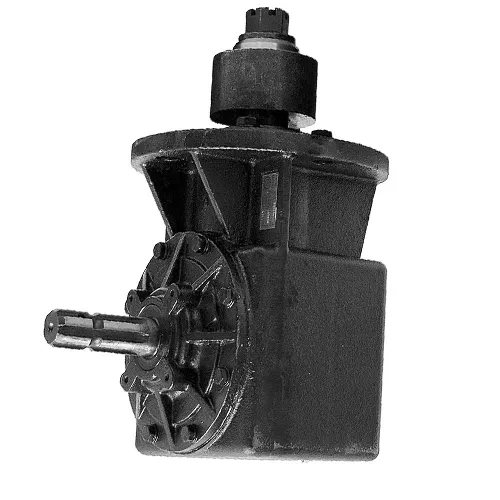

The Rotary Cutter Gearbox – Replacement of Omni Code RC-71 Gearbox is designed to offer a high-performance, durable, and cost-effective solution for replacing the Omni Code RC-71 gearbox in rotary cutter systems. Engineered to handle demanding agricultural and industrial applications, this replacement gearbox ensures reliable power transmission, smooth operation, and extended service life for rotary cutters used in mowing, land clearing, and vegetation management.

Key Features:

- High Power Capacity

The replacement gearbox is designed to handle up to 70 horsepower, making it ideal for heavy-duty tasks such as clearing large fields, cutting dense brush, and maintaining roadsides. Its robust design ensures consistent performance even in challenging conditions, providing the power needed to drive the rotary cutter blades efficiently and effectively. - Durable Construction for Long-Term Use

Built with high-quality materials, this replacement gearbox offers exceptional durability and resistance to wear, corrosion, and environmental damage. It is engineered to withstand the rigors of continuous operation in harsh conditions, ensuring long-lasting performance and reducing the frequency of maintenance or replacement. - Efficient Power Transmission

Designed for optimal power transfer, the gearbox ensures that energy is efficiently transmitted from the PTO shaft to the cutting blades with minimal power loss. This efficient transmission reduces fuel consumption and operational costs, helping operators achieve maximum cutting performance while minimizing energy waste. - Easy Installation and Compatibility

The Rotary Cutter Gearbox – Replacement of Omni Code RC-71 is designed to be a direct replacement, ensuring seamless integration with existing rotary cutter systems. Its precise compatibility with the Omni Code RC-71 gearbox allows for easy installation, with minimal adjustments required. This reduces downtime, enabling operators to get their equipment back in action quickly and efficiently. - Low Maintenance and Long Service Life

The replacement gearbox is designed for easy maintenance with features such as grease points and sealed bearings that help minimize wear and tear. The rugged construction and high-quality seals protect the internal components from dirt, moisture, and debris, reducing the need for frequent servicing. With proper care, the gearbox provides reliable performance for many years, making it a cost-effective solution for rotary cutter systems.

The Rotary Cutter Gearbox – Replacement of Omni Code RC-71 Gearbox is a high-quality, reliable, and efficient replacement solution for rotary cutters. With its durable construction, efficient power transmission, and ease of installation, it ensures reliable operation for a wide range of agricultural and industrial applications. Whether used for mowing, land clearing, or vegetation management, this replacement gearbox provides the performance needed to meet the demands of heavy-duty cutting tasks.

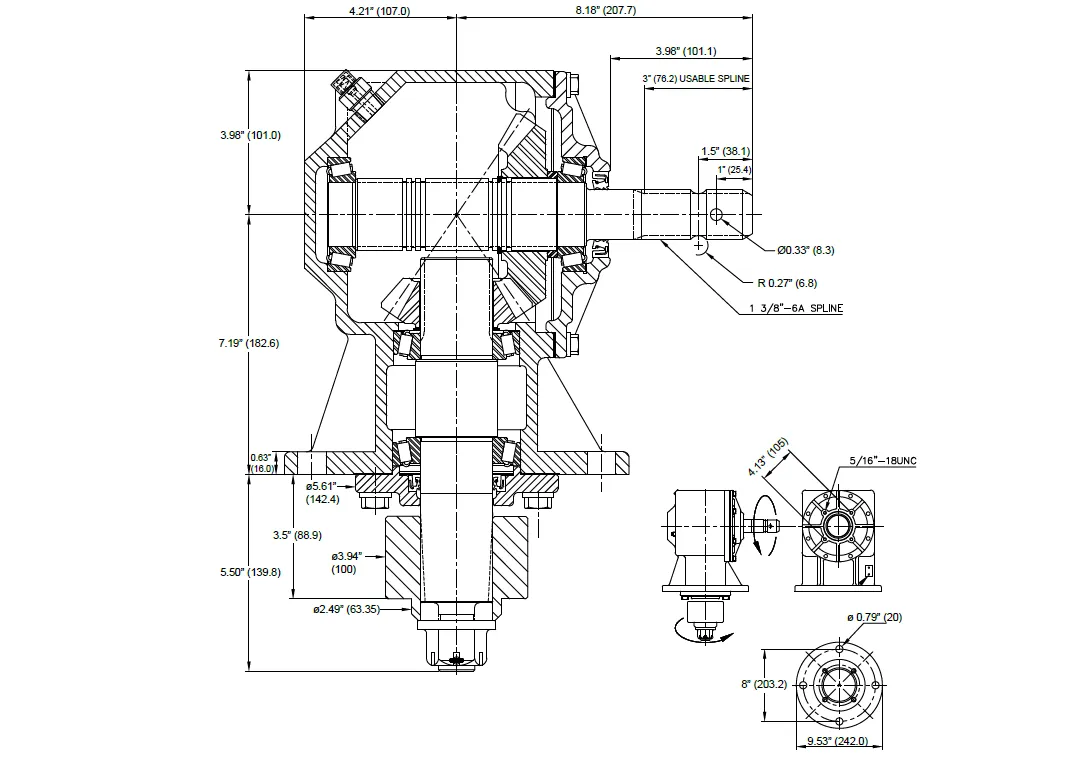

RC71 Rotary Cutter Gearbox Specifications

| Model | FMP-RC71 Rotary Cutter Gearbox |

| Torque | 4,083 – 9,683 lb.-in. (461 – 1,093 Nm.) |

| Ratios | 1.21:1, 1:1, 1:1.21, 1:1.46, 1:1.93 |

| Gear Type | Bevel |

| Seal Type | Triple Lip Spring Loaded |

| Bearing Type | Tapered Roller |

| Oil Capacity | 35 oz. (1.04 L) |

| Weight | 83 lbs. (37.7 kg.) |

How to Replacement Rotary Cutter Gearbox for Rotary Cutter?

Replacing a rotary cutter gearbox is a straightforward process, but it requires careful attention to detail and safety procedures to ensure that the new gearbox is properly installed and the machine functions correctly. Below is a step-by-step guide to replace the rotary cutter gearbox on your rotary cutter.

Tools and Equipment Needed:

- Wrench set or socket set

- Screwdrivers (flathead and Phillips)

- Lifting equipment (e.g., hoist or jack) for heavy gearboxes

- Safety gloves and goggles

- Replacement rotary cutter gearbox

- Lubricant (if required)

Step 1: Preparation and Safety First

- Park the Tractor Safely: Ensure the tractor is turned off and the keys are removed to prevent accidental starting. Place the tractor on a flat surface, ensuring it is stable.

- Wear Protective Gear: Put on safety gloves and goggles to protect yourself from potential sharp parts or debris.

- Disconnect the PTO Shaft: Before replacing the gearbox, disconnect the PTO shaft from the old gearbox. This can be done by loosening the fasteners securing the PTO shaft to the gearbox. Be sure to support the shaft to prevent it from falling or causing injury.

Step 2: Remove the Old Gearbox

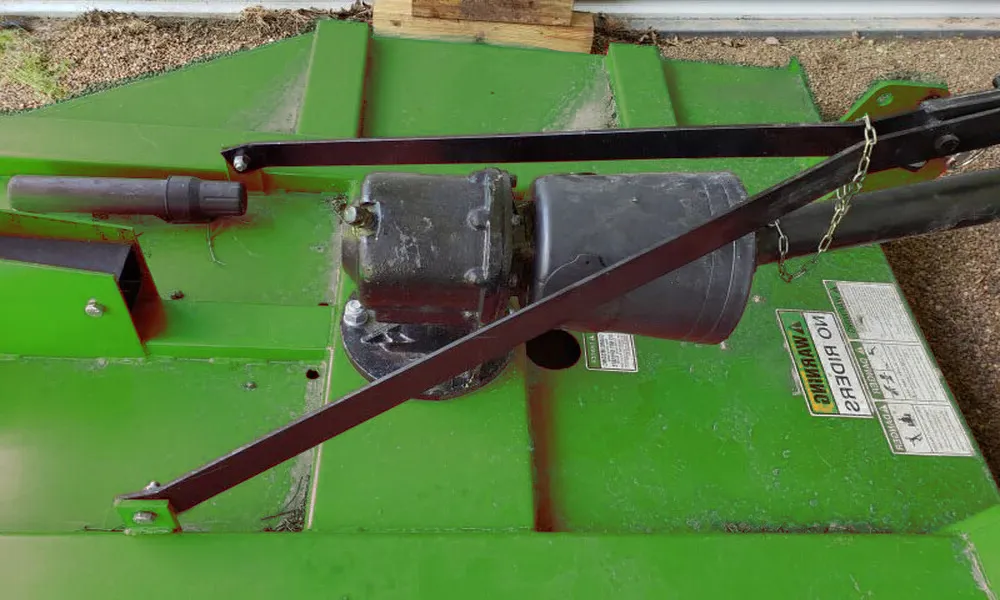

- Lift the Rotary Cutter: Use a hoist, jack, or other lifting equipment to raise the rotary cutter slightly off the ground if necessary. This will provide better access to the gearbox and reduce strain during removal.

- Loosen and Remove the Mounting Bolts: Locate the bolts or fasteners that secure the gearbox to the rotary cutter frame. Using a wrench or socket set, loosen and remove the mounting bolts. Keep track of these bolts as you will need them for the new gearbox.

- Disconnect the Drive Shaft or Input Shaft: If the rotary cutter gearbox has a drive shaft or input shaft connected to the blades or cutting mechanism, remove any additional bolts or fasteners holding it in place. Carefully slide the shaft out of the gearbox if applicable.

- Remove the Gearbox: Once all bolts and fasteners are removed, carefully lift the old gearbox off the machine. You may need assistance with this if the gearbox is heavy.

Step 3: Install the New Gearbox

- Position the New Gearbox: Align the new gearbox with the mounting holes on the rotary cutter frame. Carefully position the gearbox in place. Ensure the input shaft or the drive shaft lines up properly with the cutting mechanism or the PTO connection point.

- Secure the Gearbox: Insert and tighten the bolts or fasteners that hold the gearbox to the frame. Make sure the gearbox is securely mounted and that it does not move when pressure is applied.

- Reconnect the PTO Shaft: Attach the PTO shaft to the new gearbox. Align the PTO shaft and the gearbox input shaft, and secure it with the necessary fasteners. Be sure to tighten all connections to the manufacturer’s specifications to prevent any slippage during operation.

Step 4: Lubrication and Testing

- Lubricate the Gearbox: If the new gearbox requires lubrication, fill it with the recommended oil or grease as specified by the manufacturer. Check the oil levels and ensure the gearbox is properly lubricated to avoid overheating or wear during operation.

- Check Alignment: Before fully reassembling the rotary cutter, double-check that the gearbox is properly aligned with the PTO shaft and that there is no misalignment or binding in the gears.

- Test the Rotary Cutter: After the gearbox is installed and secured, reconnect the PTO to the tractor and run the rotary cutter briefly at low speed to ensure everything is functioning correctly. Listen for any unusual noises or vibrations, as these could indicate issues with installation, such as misalignment.

Step 5: Final Inspection

- Inspect for Leaks: After the initial test run, check the new gearbox for any oil leaks. If leaks are present, tighten the seals or bolts as needed.

- Ensure Proper Operation: Test the rotary cutter on a more substantial load, such as mowing or clearing grass, to ensure that the gearbox operates smoothly under normal conditions.

Replacing a rotary cutter gearbox is a relatively simple task if done carefully and methodically. Proper installation of the new gearbox ensures optimal performance, longevity, and safety for your rotary cutter. By following the steps outlined above, you can complete the replacement effectively and ensure that the new gearbox operates as expected, providing reliable power transfer and efficient cutting for your machinery.

PTO Shafts for Rotary Cutter Gearboxes

The PTO shafts for rotary cutter gearboxes are essential components designed to transfer mechanical power from the tractor’s Power Take-Off (PTO) system to the rotary cutter gearbox, enabling efficient operation of the cutting blades. These shafts are built for durability, high performance, and easy integration with rotary cutters, making them a crucial part of the overall power transmission system. Below are key features and benefits of using PTO shafts for rotary cutter gearboxes.

Durable and Heavy-Duty Construction

PTO shafts for rotary cutter gearboxes are constructed from high-strength steel, designed to withstand the demanding conditions of agricultural and industrial environments. These shafts can endure heavy torque loads, continuous operation, and exposure to harsh weather conditions such as moisture, dirt, and dust. Their robust design ensures reliable performance over time, even when used in rough or uneven terrain, making them ideal for land clearing, mowing, and other heavy-duty cutting tasks.

Efficient Power Transmission

The primary role of the PTO shaft is to transfer power from the tractor’s PTO system to the rotary cutter gearbox with minimal energy loss. This efficient power transmission optimizes the performance of the rotary cutter, ensuring that the cutting blades operate at the desired speed and power. By reducing energy waste, the PTO shaft helps improve fuel efficiency and reduce operational costs, making it a cost-effective solution for agricultural and industrial cutting applications.

Safety Features

Safety is a critical consideration in the design of PTO shafts for rotary cutter gearboxes. These shafts are equipped with protective shields and covers that prevent accidental contact with rotating parts. In addition, the PTO shafts are often designed to minimize vibrations, ensuring smoother operation and reducing the risk of damage to the gearbox and other components. These safety features contribute to a safer work environment, minimizing the risk of operator injury and extending the lifespan of the machinery.

Universal Compatibility and Easy Installation

PTO shafts for rotary cutter gearboxes are designed to be universally compatible with a wide range of rotary cutters and tractors. This versatility allows them to be used in various agricultural, landscaping, and industrial applications without the need for complex modifications. The PTO shafts are easy to install, typically requiring just a few bolts or fasteners to secure them to the gearbox and tractor PTO system. This ease of installation reduces downtime, allowing operators to quickly get their equipment back in operation.

Low Maintenance and Longevity

PTO shafts for rotary cutter gearboxes require minimal maintenance due to their durable construction and design. Most shafts feature sealed bearings and grease points that help reduce wear and tear, ensuring smooth operation with minimal servicing. Regular maintenance, such as checking for lubrication and ensuring proper alignment, is sufficient to extend the lifespan of the PTO shaft. With proper care, these shafts can provide many years of reliable performance, making them a long-term investment for rotary cutter systems.

PTO shafts for rotary cutter gearboxes are essential for ensuring reliable, efficient, and safe operation of rotary cutters in agricultural and industrial settings. Their heavy-duty construction, efficient power transmission, safety features, and ease of maintenance make them indispensable components for maintaining optimal performance of rotary cutter systems. Whether used for mowing, land clearing, or brush cutting, PTO shafts provide the necessary power and reliability to meet the demands of heavy-duty cutting tasks.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX