Rotary Cutter Gearboxes – Replacement of Omni Code RC-130 Gearbox

The Rotary Cutter Gearbox – Replacement of Omni Code RC-130 Gearbox is a high-performance replacement solution designed to seamlessly replace the Omni Code RC-130 gearbox in rotary cutter systems. This gearbox is engineered to meet the demands of heavy-duty agricultural, industrial, and land maintenance tasks, offering reliable power transmission, durability, and optimal cutting performance. Whether used for large-scale mowing, land clearing, or vegetation management, the RC-130 replacement gearbox provides an efficient solution for maintaining smooth and consistent operation of rotary cutter blades.

Key Features:

- High Power Handling Capacity

The RC-130 replacement gearbox is designed to support up to 130 horsepower, making it ideal for demanding applications such as large-scale mowing, brush clearing, and vegetation management. This high power capacity ensures that the rotary cutter blades can tackle dense vegetation, heavy brush, and rough terrain with ease, making it an essential tool for both agricultural and industrial applications. - Durable and Robust Construction

Built to withstand harsh environments, the RC-130 gearbox features a heavy-duty design that resists wear and tear, ensuring long-lasting performance. Its corrosion-resistant housing protects the gearbox from environmental damage, making it suitable for continuous outdoor operation under challenging conditions. The robust construction guarantees minimal downtime and maintenance requirements, offering reliable performance over the long term. - Efficient Power Transmission

The RC-130 replacement gearbox ensures efficient power transfer from the PTO shaft to the rotary cutter blades. The gearbox reduces the speed and increases the torque from the tractor’s PTO system to provide optimal cutting performance. With a precise gear system, the gearbox ensures that the rotary cutter blades operate smoothly, efficiently, and consistently, reducing energy consumption and improving cutting quality.

The Rotary Cutter Gearbox – Replacement of Omni Code RC-130 Gearbox offers an efficient, high-performance solution for rotary cutter systems. With its high power capacity, durable construction, efficient power transmission, and easy installation, this gearbox ensures smooth, reliable operation in a variety of heavy-duty applications. Designed to minimize downtime and maintenance requirements, the RC-130 replacement gearbox is an ideal choice for operators seeking to maintain optimal cutting performance in demanding environments.

Specifications of RC-145 Rotary Cutter Gearbox

| Model: | FMP-RC-145 Rotary Cutter Gearbox |

| Rotation: | CW input gives CW output |

| Gear Ratio: | 1:1.833 |

| Input RPM: | 540/1000 rmp |

| Output RPM: | 989/1833 rmp |

| Input HP: | 61-171 hp |

| Max Torque: | 7117-19950 in.lbs. |

| Input Shaft: | 1-3/4″ dia. x 3-7/8″ long 20T spline |

| Output Shaft: | 2-1/4″ dia. 18 tooth tapered spline w/threaded end. 3-1/4″ total length |

| Mount: | 6 holes on 8″ dia. B.C. |

| Pilot: | 5-5/8″ dia. |

| Centerline Distance: | 8.9″ (input shaft to the mounting surface) |

| Size: | 14-1/2″ x 11″ x 11″ |

| Actual Weight: | 120 lbs. |

Advantages of Using RC-145 Rotary Cutter Gearboxes

The RC-145 Rotary Cutter Gearbox offers several key advantages that make it an ideal choice for a variety of agricultural, industrial, and vegetation management applications. Built for durability, performance, and ease of use, this gearbox provides significant benefits to operators who rely on rotary cutters for heavy-duty tasks such as mowing, brush clearing, and land maintenance.

High Power Capacity for Heavy-Duty Applications

One of the standout features of the RC-145 Rotary Cutter Gearbox is its ability to handle up to 145 horsepower, making it perfect for high-demand tasks. Whether clearing dense brush, mowing large fields, or managing rough terrain, the gearbox ensures optimal power transfer to the rotary cutter blades. This high power capacity enables operators to tackle heavy vegetation and tough cutting conditions without compromising performance, offering efficient results in large-scale agricultural and industrial operations.

Durable Construction for Longevity

The RC-145 gearbox is built with heavy-duty materials designed to withstand tough working environments. Its robust housing and components are resistant to wear and tear, ensuring long-lasting durability even under extreme conditions. This durability significantly reduces the need for frequent repairs and downtime, enhancing the overall efficiency of the rotary cutter system. The gearbox’s ability to resist corrosion and handle exposure to dirt, moisture, and debris ensures reliable performance over extended periods.

Efficient Power Transmission

With its advanced gear system, the RC-145 gearbox ensures efficient power transmission from the PTO shaft to the rotary cutter blades. The gearbox reduces rotational speed from the tractor’s PTO to the optimal RPM required for cutting, providing smooth blade operation and consistent performance. This efficiency minimizes energy loss, improves cutting quality, and contributes to lower fuel consumption, making it a more cost-effective solution for operators in the long run.

Easy Installation and Compatibility

The RC-145 gearbox is designed for easy installation and direct compatibility with rotary cutter systems that use the Omni Code RC-145 gearbox. Its precision engineering allows for a seamless fit, minimizing downtime during installation and reducing the need for additional adjustments. This ease of integration ensures that operators can quickly replace or upgrade the gearbox, reducing maintenance costs and allowing for uninterrupted workflow in demanding applications.

Low Maintenance Requirements

The RC-145 rotary cutter gearbox is designed with low maintenance in mind. With high-quality bearings, seals, and lubrication systems, it requires minimal upkeep while maintaining excellent performance. Routine inspections and regular lubrication are typically the only maintenance tasks required to keep the gearbox running smoothly. The reduced need for repairs and the extended service life of the gearbox make it an economical choice for operators looking to optimize their machinery’s uptime.

The RC-145 Rotary Cutter Gearbox offers numerous advantages, including its high power capacity, durable construction, efficient power transmission, ease of installation, and low maintenance requirements. These features combine to provide a reliable, cost-effective solution for rotary cutter systems used in heavy-duty applications. Whether for agricultural, industrial, or land maintenance tasks, the RC-145 gearbox ensures consistent performance, reduces downtime, and enhances the overall efficiency of rotary cutting operations.

|

|

Advantages of Using RC-145 Rotary Cutter Gearboxes

The RC-145 Rotary Cutter Gearbox offers several key advantages that make it an ideal choice for a variety of agricultural, industrial, and vegetation management applications. Built for durability, performance, and ease of use, this gearbox provides significant benefits to operators who rely on rotary cutters for heavy-duty tasks such as mowing, brush clearing, and land maintenance.

High Power Capacity for Heavy-Duty Applications

One of the standout features of the RC-145 Rotary Cutter Gearbox is its ability to handle up to 145 horsepower, making it perfect for high-demand tasks. Whether clearing dense brush, mowing large fields, or managing rough terrain, the gearbox ensures optimal power transfer to the rotary cutter blades. This high power capacity enables operators to tackle heavy vegetation and tough cutting conditions without compromising performance, offering efficient results in large-scale agricultural and industrial operations.

Durable Construction for Longevity

The RC-145 gearbox is built with heavy-duty materials designed to withstand tough working environments. Its robust housing and components are resistant to wear and tear, ensuring long-lasting durability even under extreme conditions. This durability significantly reduces the need for frequent repairs and downtime, enhancing the overall efficiency of the rotary cutter system. The gearbox’s ability to resist corrosion and handle exposure to dirt, moisture, and debris ensures reliable performance over extended periods.

Efficient Power Transmission

With its advanced gear system, the RC-145 gearbox ensures efficient power transmission from the PTO shaft to the rotary cutter blades. The gearbox reduces rotational speed from the tractor’s PTO to the optimal RPM required for cutting, providing smooth blade operation and consistent performance. This efficiency minimizes energy loss, improves cutting quality, and contributes to lower fuel consumption, making it a more cost-effective solution for operators in the long run.

Easy Installation and Compatibility

The RC-145 gearbox is designed for easy installation and direct compatibility with rotary cutter systems that use the Omni Code RC-145 gearbox. Its precision engineering allows for a seamless fit, minimizing downtime during installation and reducing the need for additional adjustments. This ease of integration ensures that operators can quickly replace or upgrade the gearbox, reducing maintenance costs and allowing for uninterrupted workflow in demanding applications.

Low Maintenance Requirements

The RC-145 rotary cutter gearbox is designed with low maintenance in mind. With high-quality bearings, seals, and lubrication systems, it requires minimal upkeep while maintaining excellent performance. Routine inspections and regular lubrication are typically the only maintenance tasks required to keep the gearbox running smoothly. The reduced need for repairs and the extended service life of the gearbox make it an economical choice for operators looking to optimize their machinery’s uptime.

The RC-145 Rotary Cutter Gearbox offers numerous advantages, including its high power capacity, durable construction, efficient power transmission, ease of installation, and low maintenance requirements. These features combine to provide a reliable, cost-effective solution for rotary cutter systems used in heavy-duty applications. Whether for agricultural, industrial, or land maintenance tasks, the RC-145 gearbox ensures consistent performance, reduces downtime, and enhances the overall efficiency of rotary cutting operations.

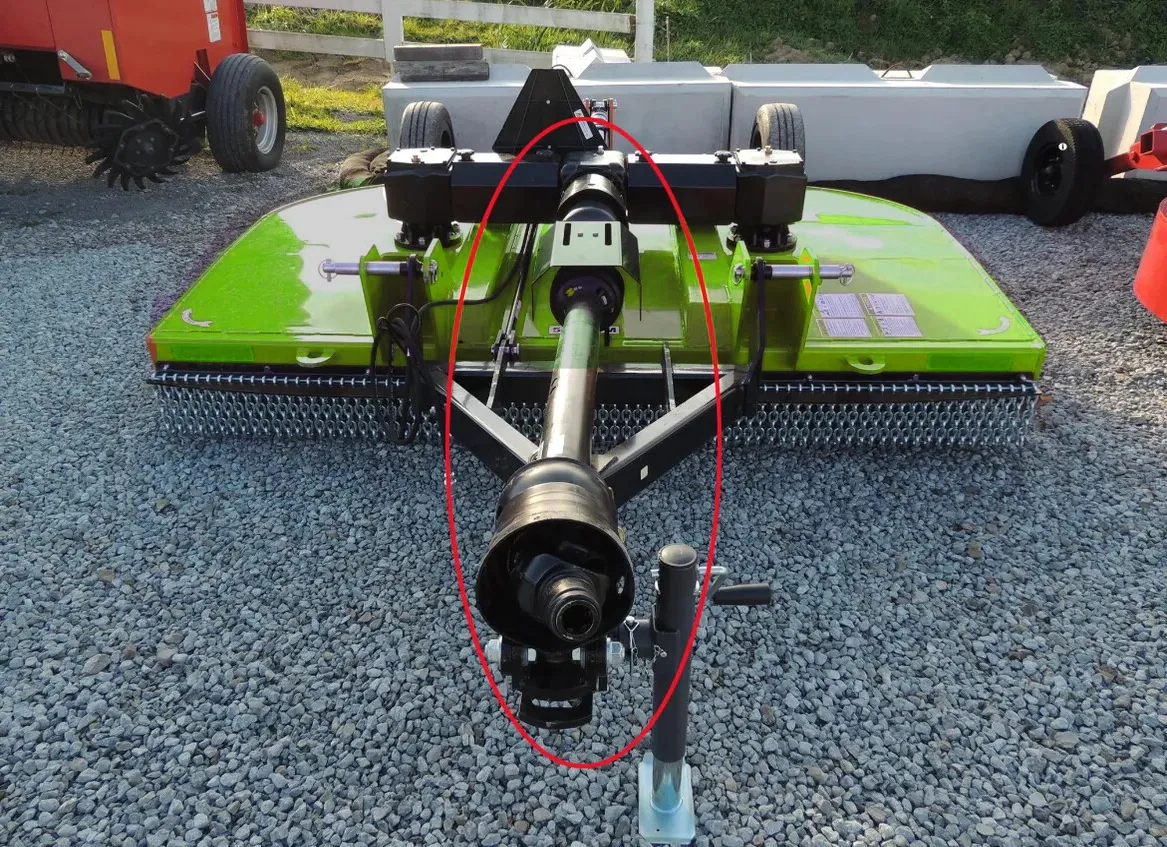

PTO Shafts for the RC-145 Rotary Cutter Gearbox

PTO shafts play a critical role in powering the RC-145 Rotary Cutter Gearbox, serving as the key component that transfers mechanical power from the tractor’s PTO system to the gearbox, which in turn drives the rotary cutter blades. These shafts are essential for ensuring smooth, efficient, and reliable operation of rotary cutter systems, making them indispensable for various agricultural and industrial applications.

Efficient Power Transmission

The PTO shaft connects the tractor’s PTO system to the RC-145 rotary cutter gearbox, transmitting rotational power to the gearbox. This power is then reduced to the optimal RPM for operating the cutter blades. PTO shafts are designed to efficiently handle the high torque and power requirements of heavy-duty cutting tasks, ensuring that the rotary cutter blades operate smoothly and consistently, even under demanding conditions such as dense vegetation or rough terrains.

Durable Construction for Long-Lasting Performance

Built from high-strength materials, PTO shafts for the RC-145 gearbox are designed to withstand the stresses and vibrations of heavy-duty agricultural and industrial applications. The robust construction ensures that the shaft can handle the high power output required to operate the rotary cutter system reliably over long periods of use. This durability reduces the need for frequent replacements and repairs, providing a long service life and minimizing operational costs.

Safety Features

PTO shafts come equipped with essential safety features, such as shear pins and protective shields, to prevent accidents and equipment damage. In the event of a sudden overload or obstruction, the shear pin will break, disconnecting the PTO shaft and preventing damage to both the shaft and the RC-145 gearbox. The protective shield ensures that the rotating shaft is safely covered to prevent accidental contact during operation, promoting operator safety in the field.

Customizable Length and Configuration

PTO shafts for the RC-145 Rotary Cutter Gearbox are available in various lengths and configurations to match the specific requirements of different tractors and rotary cutter models. Whether you need a single-speed or variable-speed shaft, or a shaft designed to fit specific PTO attachment points, PTO shafts for the RC-145 gearbox can be tailored to ensure optimal fit and functionality. Customization ensures that the power transfer between the tractor and the gearbox is both efficient and secure.

Ease of Use and Maintenance

PTO shafts are designed for ease of use, with features that make them simple to install and detach. The universal joint at both ends of the shaft ensures smooth flexibility, allowing for easy connection and disconnection between the tractor and the RC-145 gearbox. Regular maintenance involves simple tasks such as lubrication and inspection for wear and tear, making it easy to maintain the PTO shaft’s performance and extend its service life. Proper maintenance ensures that the shaft continues to transfer power effectively, minimizing downtime and optimizing productivity.

PTO shafts for the RC-145 Rotary Cutter Gearbox are essential components that ensure efficient power transmission from the tractor to the gearbox, driving the rotary cutter blades for high-performance operation. With their durable construction, safety features, customizable configurations, and ease of use, these PTO shafts provide reliable and long-lasting performance for demanding agricultural and industrial applications. Proper maintenance of the PTO shaft is critical for maintaining smooth, efficient operation, making it an indispensable part of the rotary cutting system.

|

|

Typical Applications of RC-145 Rotary Cutter Gearbox

The RC-145 Rotary Cutter Gearbox is a versatile and durable solution designed to power rotary cutter systems for a wide range of applications in agricultural, industrial, and land maintenance sectors. Its high power capacity, efficiency, and robust construction make it an ideal choice for demanding tasks that require reliable performance in challenging environments. Below are some of the typical applications where the RC-145 rotary cutter gearbox excels:

Agricultural Field Maintenance

In agriculture, the RC-145 gearbox is used for field maintenance, including mowing grass, cutting hay, and managing pasturelands. It powers rotary cutters that can efficiently trim large areas of grass, weeds, and small vegetation. Its high horsepower capacity makes it ideal for large-scale farming operations where speed and reliability are critical for maintaining crops and preventing overgrowth. The gearbox ensures optimal cutting performance and minimal downtime, crucial for time-sensitive agricultural tasks.

Land Clearing and Brush Cutting

The RC-145 gearbox is perfectly suited for land clearing and brush cutting applications. It provides the necessary power to rotary cutters that can handle thick brush, small trees, and dense vegetation, making it a go-to solution for forestry, construction sites, and other land clearing projects. Whether preparing land for development or clearing pathways, the gearbox ensures that rotary cutters can tackle heavy-duty vegetation management tasks efficiently, even in challenging terrains.

Roadside and Highway Maintenance

Local governments and contractors rely on the RC-145 gearbox for roadside and highway vegetation management. The gearbox powers rotary cutters that trim grass, remove weeds, and maintain clear sightlines along roads and highways. It is ideal for managing vegetation in areas that require regular upkeep, including road shoulders, ditches, and median strips. With its ability to manage large areas of roadside vegetation quickly, the RC-145 gearbox helps improve the appearance and safety of public roads.

Municipal Parks and Green Space Maintenance

In municipal applications, the RC-145 rotary cutter gearbox is used for maintaining parks, sports fields, golf courses, and other recreational areas. The gearbox powers rotary cutters that ensure smooth, even cuts in grassy areas, while its high power capacity allows it to efficiently handle rougher vegetation around the perimeter of parks and public spaces. Operators can rely on the gearbox to deliver consistent performance, making it an essential tool for keeping urban green spaces clean and well-maintained.

Industrial Vegetation Control

The RC-145 rotary cutter gearbox is commonly used in industrial settings to control vegetation growth on large estates, around facilities, and on power plant grounds. Industrial sites often require vegetation management to prevent overgrowth that can interfere with operations or pose safety risks. The RC-145 gearbox powers rotary cutters that clear grass, shrubs, and weeds around industrial sites, ensuring that the environment remains clear and safe for workers. Its ability to handle heavy-duty tasks makes it perfect for large-scale industrial properties and energy facilities.

The RC-145 Rotary Cutter Gearbox is a reliable and powerful component that supports various applications in agriculture, land clearing, municipal maintenance, and industrial vegetation control. Its high horsepower, efficient power transmission, and durable construction make it an ideal solution for challenging cutting tasks, ensuring optimal performance and reduced downtime in all types of rotary cutter systems. Whether used for maintaining fields, clearing land, or managing roadside vegetation, the RC-145 gearbox enhances productivity and reliability in demanding environments.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX