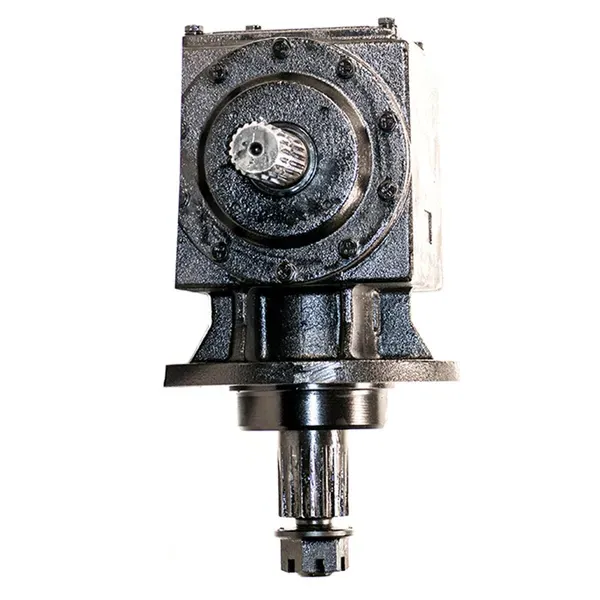

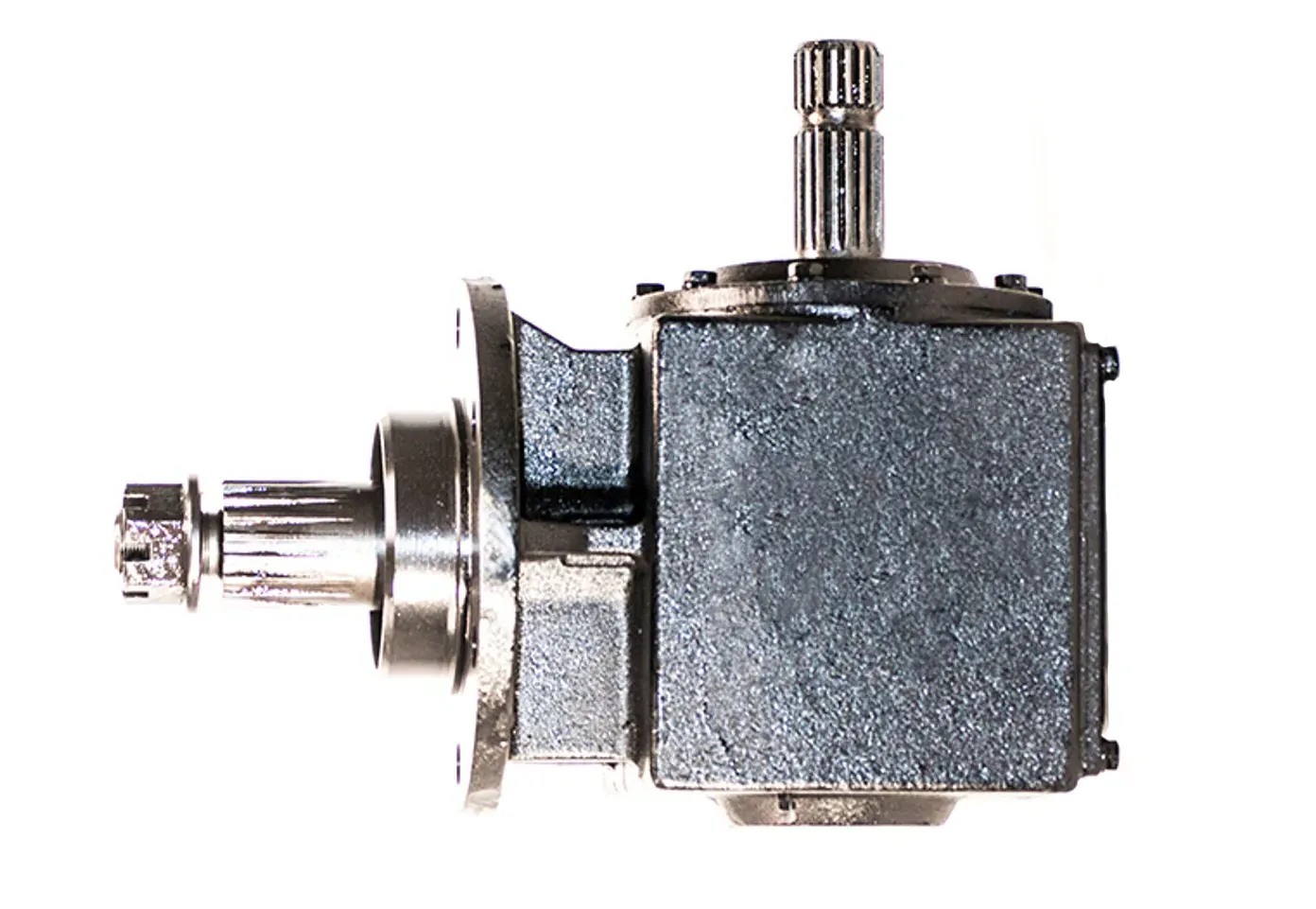

Rotary Cutter Gearboxes – Replacement of Omni Code RC-130 Gearbox

The Rotary Cutter Gearbox – Replacement of Omni Code RC-130 Gearbox is a robust, high-performance gearbox specifically engineered to replace the Omni Code RC-130 gearbox in rotary cutter systems. Designed for heavy-duty agricultural, industrial, and land management applications, this gearbox offers superior power transmission, reliability, and durability. It ensures optimal cutting performance in demanding conditions, making it ideal for use in mowing, brush clearing, and vegetation management across large-scale operations.

Key Features:

- High Horsepower Capacity

The RC-130 replacement gearbox is designed to handle up to 130 horsepower, ensuring it can meet the power demands of large rotary cutters in various applications. This capacity allows the gearbox to efficiently handle dense vegetation, rough terrain, and challenging cutting conditions without compromising performance. - Durable and Rugged Construction

Constructed with high-strength materials, the RC-130 gearbox is built to withstand harsh environmental conditions and prolonged use. Its corrosion-resistant housing and reinforced components provide exceptional durability, allowing the gearbox to operate efficiently in tough agricultural and industrial environments. This robust design ensures minimal maintenance and extended service life. - Efficient Power Transmission

The gearbox features an advanced gearing system that efficiently transfers power from the tractor’s PTO system to the rotary cutter blades. By reducing the tractor’s RPM to the ideal cutting speed and increasing torque, the RC-130 gearbox ensures smooth, consistent blade rotation, delivering optimal cutting performance while reducing energy consumption and operational costs.

The Rotary Cutter Gearbox – Replacement of Omni Code RC-130 Gearbox is a high-performance, durable, and efficient solution for rotary cutter systems. Designed to deliver smooth power transmission, exceptional durability, and easy installation, this gearbox is perfect for heavy-duty applications in agriculture, land clearing, roadside maintenance, and industrial settings. With its low-maintenance design and long-lasting performance, the RC-130 replacement gearbox ensures optimal cutting efficiency and minimal downtime, making it an excellent choice for operators looking to enhance their rotary cutter systems.

Specifications of RC130 Rotary Cutter Gearbox

| Model: | FMP-RC130 Rotary Cutter Gearbox |

| Power: | 47 – 104 hp 35 – 78 kW |

| Applications: | Finishing Mowers Rotary Cutters Rotary Slashers |

| Torque: | 7,117 – 19,950 lb.-in. (803 – 2,252 Nm.) |

| Ratios: | 1.21:1, 1:1, 1:1.21, 1:1.46, 1:1.92 |

| Gear Type: | Bevel |

| Seal Type: | Triple Lip Spring Loaded |

| Bearing Type: | Tapered Roller |

| Oil Capacity: | 60 oz. (1.8 L) |

| Weight: | 109 lbs. (49.9 kg.) |

How to Attach a Rotary Cutter Gearbox to a Rotary Cutter

Attaching a rotary cutter gearbox to a rotary cutter is a straightforward process, but it requires proper care and attention to detail to ensure safe, efficient, and reliable operation. Below are the steps to attach a rotary cutter gearbox to a rotary cutter:

Prepare the Necessary Tools and Equipment

Before beginning the installation, gather all necessary tools, including wrenches, bolts, safety gloves, and any specific tools required for your specific gearbox model. Make sure the tractor is safely parked on a level surface, and ensure that the PTO (Power Take-Off) shaft is disconnected to prevent accidental engagement. It’s also important to check the condition of the gearbox, PTO shaft, and cutter system to ensure they are clean and free from damage.

Align the Gearbox with the Cutter Deck

Position the rotary cutter gearbox near the cutter deck, ensuring that the input shaft (the shaft that connects to the PTO) is aligned with the corresponding connection point on the cutter deck. Carefully lift or position the gearbox into place, ensuring the mounting holes on the gearbox line up with the attachment points on the cutter deck. This step requires careful alignment to avoid damage to the gearbox or the cutter deck during installation.

Secure the Gearbox to the Cutter Deck

Once the gearbox is properly aligned with the cutter deck, use the provided bolts and mounting hardware to secure the gearbox to the deck. Tighten the bolts evenly using the appropriate tools to ensure a solid, stable connection. Be sure to follow any specific torque requirements provided by the manufacturer to avoid over-tightening, which could cause damage to the gearbox or attachment points. Double-check that all bolts are securely fastened before moving on to the next step.

Connect the PTO Shaft to the Gearbox

Next, connect the PTO shaft to the input shaft of the gearbox. The PTO shaft should be properly aligned with the gearbox’s PTO input. Ensure that the shaft is fully inserted and locked in place according to the manufacturer’s instructions. Depending on the type of PTO shaft, you may need to use a shear pin or locking mechanism to secure it. Make sure the PTO shaft is correctly installed, with no gaps or loose connections, to prevent power loss or safety hazards.

Check Alignment and Test the System

After securing the gearbox and PTO shaft, check the alignment once more to ensure there are no misalignments or binding. Confirm that the gearbox rotates freely and smoothly. Before starting full operation, it’s important to test the system at a low RPM on the tractor to ensure proper function. Listen for unusual noises or vibrations that might indicate an installation issue. If everything runs smoothly, the gearbox is now properly attached, and you can begin using the rotary cutter.

Attaching a rotary cutter gearbox to a rotary cutter involves careful preparation, alignment, and securing of components to ensure smooth and safe operation. By following these steps and ensuring the proper installation of the PTO shaft, gearbox, and cutter deck, operators can expect reliable performance and longevity from their rotary cutter system.

Agricultural PTO Shafts for Rotary Cutter Gearboxes

Agricultural PTO shafts are critical components that connect a tractor’s PTO (Power Take-Off) system to a rotary cutter gearbox, transferring mechanical power from the tractor to the cutter blades. These shafts are engineered to efficiently transmit power to rotary cutters, ensuring optimal cutting performance in agricultural applications such as mowing, brush clearing, and land management. Designed for durability, safety, and ease of use, PTO shafts for rotary cutter gearboxes are built to withstand the high torque demands of heavy-duty farming and industrial operations.

Efficient Power Transmission

PTO shafts for rotary cutter gearboxes are designed to efficiently transfer power from the tractor’s PTO system to the rotary cutter gearbox, which in turn drives the cutter blades. The shaft ensures smooth and reliable power transmission at the required RPM, enabling the rotary cutter to handle dense vegetation, rough terrain, and large-scale operations. The design of the PTO shaft minimizes energy loss during power transfer, making the system more efficient and reducing fuel consumption.

Heavy-Duty Construction

PTO shafts for rotary cutter gearboxes are built with heavy-duty materials to handle the stresses of high-torque operations. They are typically constructed from high-strength steel and feature durable universal joints that ensure flexibility and smooth operation even under extreme loads. This robust construction enables the PTO shafts to perform reliably in challenging agricultural environments, such as when cutting through thick brush or rough terrain.

Safety Features

PTO shafts are equipped with important safety features to prevent accidents during operation. Shear pins, clutch mechanisms, and protective shields are commonly integrated into the design. The shear pin helps protect the PTO shaft and gearbox from overload by breaking if the system encounters excessive resistance. The protective shield covers the rotating shaft to prevent accidental contact with operators or nearby equipment, promoting safety in the field.

Customizable Length and Fit

Agricultural PTO shafts for rotary cutter gearboxes are available in various lengths and configurations to suit different tractor models and cutter systems. Depending on the required reach and tractor specifications, PTO shafts can be customized to ensure a perfect fit. Whether you need a single-speed or multi-speed shaft, PTO shafts can be tailored to match the specific needs of your rotary cutter, ensuring seamless power transfer and efficient operation.

Ease of Installation and Maintenance

PTO shafts are designed for easy installation and removal, allowing for quick connection and disconnection between the tractor and rotary cutter gearbox. The universal joint design ensures flexibility, accommodating slight misalignments between the PTO shaft and gearbox input. Regular maintenance of PTO shafts includes lubrication and inspection for wear and tear, such as checking for cracks or worn joints. Proper maintenance extends the life of the PTO shaft and ensures continued reliable operation.

Agricultural PTO shafts for rotary cutter gearboxes are essential components for transferring power from the tractor’s PTO system to the cutter blades, ensuring efficient, reliable cutting performance in a variety of agricultural applications. With their heavy-duty construction, safety features, and customizable fit, PTO shafts are built to withstand the demands of large-scale farming and land management. Regular maintenance and correct installation ensure long-term performance, making PTO shafts an indispensable part of a rotary cutter system.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX