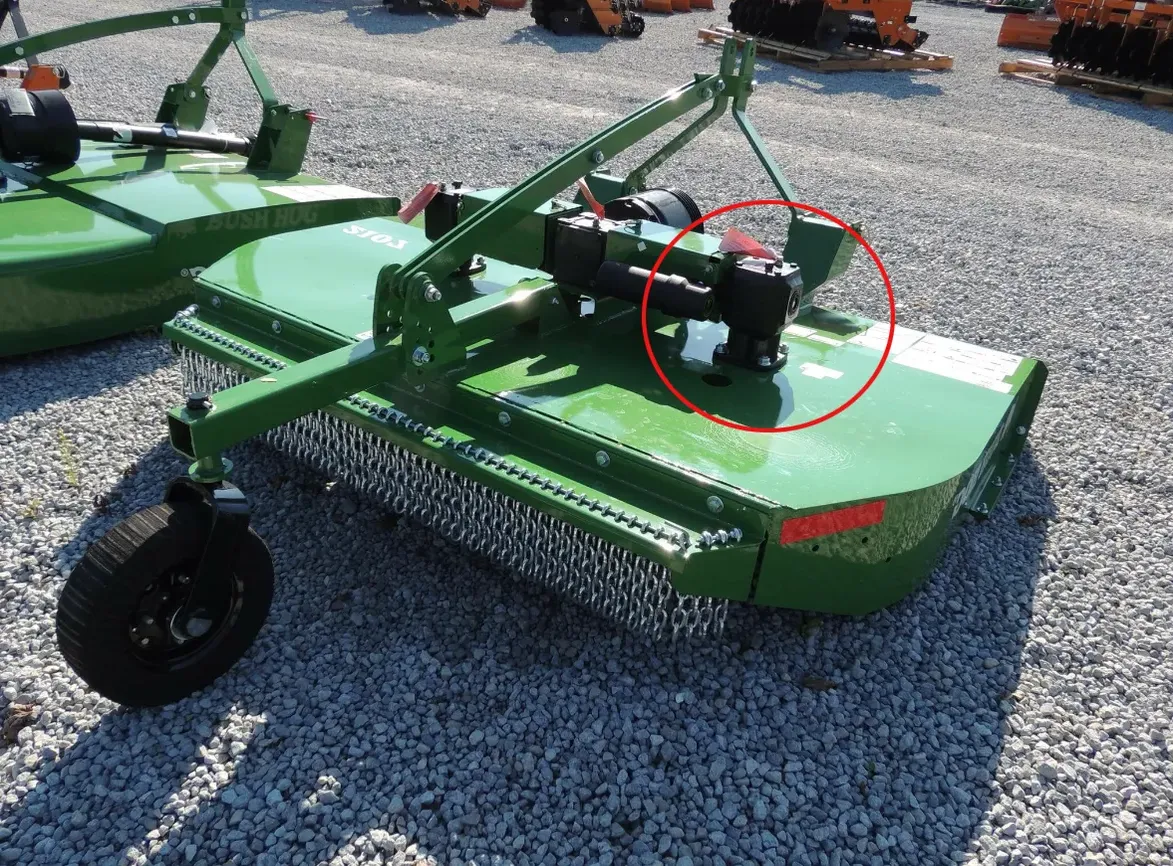

Rotary Cutter Gearbox for Rotary Cutter – Replacement for Omni Gearbox RC61

The Rotary Cutter Gearbox for Rotary Cutter – Replacement for Omni Gearbox RC61 is a high-quality, durable gearbox designed to replace the Omni Gearbox RC61, offering seamless compatibility and enhanced performance for rotary cutters used in agricultural and industrial applications. This replacement gearbox ensures the same reliable power transmission and cutting efficiency as the original, while incorporating modern design improvements to extend its lifespan and reduce maintenance costs.

|

|

- Direct Replacement for Omni Gearbox RC61

Designed to match the specifications of the Omni RC61, this replacement gearbox is a direct fit for rotary cutters previously equipped with the Omni gearbox. It ensures hassle-free installation, minimizing downtime and ensuring that your equipment is back in operation quickly.

- High Power Capacity

The replacement gearbox is built to handle the power requirements of heavy-duty rotary cutters, providing reliable performance for tasks such as mowing, land clearing, and brush cutting. It ensures smooth and efficient power transfer from the tractor’s PTO to the cutting blades, optimizing operational efficiency.

- Enhanced Durability and Performance

Constructed with high-strength, wear-resistant materials, the replacement gearbox offers improved durability and longevity compared to the original Omni RC61. It is designed to withstand demanding agricultural and industrial conditions, including rough terrain, dense vegetation, and continuous operation, making it a reliable solution for tough tasks.

- Improved Heat Dissipation

The gearbox is engineered with superior heat management capabilities, ensuring it operates efficiently even under heavy load and extended use. The improved heat dissipation reduces the risk of overheating and prolongs the lifespan of both the gearbox and the rotary cutter, maintaining peak performance throughout the workday.

- Low Maintenance and Easy Servicing

The replacement gearbox is designed for ease of maintenance, with accessible grease points and sealed bearings that reduce the need for frequent lubrication. The robust design and efficient sealing mechanisms protect against dirt, moisture, and contaminants, reducing wear and the frequency of service requirements.

The Rotary Cutter Gearbox for Rotary Cutter – Replacement for Omni Gearbox RC61 is the perfect solution for those looking to replace their Omni RC61 gearbox without compromising on performance or reliability. With enhanced durability, efficient power transmission, and easy maintenance features, this replacement gearbox ensures that your rotary cutter continues to operate at its best, even in the most challenging agricultural and industrial applications. Offering a direct replacement with improved features, it ensures minimal downtime and long-lasting reliability, making it an ideal choice for operators who demand the best from their machinery.

RC61 Rotary Cutter Gearbox Specifications:

Model: FMP-RC61

| Torque |

4,803 – 9,683 lb.-in. |

| (461 – 1,903 Nm.) |

| Ratios |

1.21:1, 1:1, 1:1.21, 1:1.46, 1:1.93 |

| Gear Type |

Bevel |

| Seal Type |

Triple Lip Spring Loaded |

| Bearing Type |

Tapered Roller |

| Oil Capacity |

32 oz. |

| (0.95 L) |

| Weight |

81 lbs. |

| (36.7 kg.) |

75 HP Rotary cutter gearbox with 1-3/8″ 6-spline input shaft and a gear ratio of 1:1.46. Cast iron housing is sealed to protect the gears and bearings. The mounting plate has four bolt holes spaced 5.5″ square. Ships without oil (16 oz of 80-90 W)

The gearbox has a piloted flange bottom to fit in a 5-5/8″ pilot hole in the mower/cutter deck.

PTO Shafts for Rotary Cutters Gearboxes

The PTO Shafts for Rotary Cutter Gearboxes play a crucial role in transferring power from the tractor’s power take-off (PTO) system to the rotary cutter gearbox, enabling the efficient operation of cutting blades. These shafts are designed to handle the high torque and demanding conditions typical of agricultural and industrial applications, ensuring reliable power transmission for a variety of rotary cutting tasks, such as mowing, land clearing, and vegetation management.

Constructed from high-strength materials, PTO shafts are built for durability, able to withstand the rigorous conditions of agricultural fields and industrial environments. Their robust construction reduces the risk of wear and tear, providing long-lasting performance with minimal need for maintenance or replacement. This makes them a cost-effective solution for operators seeking reliable equipment for heavy-duty operations.

Designed with versatility in mind, PTO shafts for rotary cutter gearboxes come in various sizes and configurations, making them compatible with a wide range of rotary cutters and gearboxes. This universal compatibility ensures that operators can easily find a suitable shaft for their specific machinery, enabling seamless integration with existing equipment without the need for additional modifications.

The PTO shafts are equipped with universal joints that facilitate smooth power transfer and reduce vibration during operation. This not only enhances the efficiency of the rotary cutter but also minimizes wear on the shaft and gearbox, prolonging the lifespan of both components. Additionally, these joints help improve operational comfort by reducing vibrations that may otherwise cause discomfort or lead to equipment damage.

Safety is a top priority with PTO shafts for rotary cutter gearboxes. They are equipped with protective safety shields that prevent accidental contact with moving parts, reducing the risk of injury during operation. With their easy maintenance design, including accessible grease points, PTO shafts require minimal servicing, ensuring smooth, uninterrupted operation and providing peace of mind to operators.

Rotary Cutter Gearbox Used in Agriculture Application

The Rotary Cutter Gearbox plays a pivotal role in agricultural machinery, particularly in rotary cutters used for mowing, land clearing, and vegetation management. This gearbox efficiently transfers power from the tractor’s PTO (Power Take-Off) system to the rotary cutter blades, ensuring smooth operation and effective cutting performance in a wide range of agricultural applications.

- Powerful and Efficient Performance

Rotary cutter gearboxes are designed to handle significant horsepower, making them suitable for heavy-duty agricultural tasks. They efficiently convert the power from the tractor’s PTO into rotational force for the cutting blades, ensuring high performance even in dense or tough vegetation. This power transfer minimizes energy losses and optimizes cutting efficiency, reducing fuel consumption and operational costs.

- Durability and Reliability

Agricultural environments can be harsh, with rough terrain and constant exposure to elements like dirt, moisture, and chemicals. Rotary cutter gearboxes are built to withstand these conditions, with durable construction and materials that resist wear and corrosion. Their robust design ensures long-term reliability and reduced maintenance needs, making them ideal for farmers and operators who rely on machinery for extended periods of time.

- Versatility in Agricultural Operations

Rotary cutter gearboxes are versatile and can be used in various agricultural applications, including mowing large fields, clearing weeds and brush, managing grass, and maintaining roadsides. These gearboxes can be adapted to different models of rotary cutters, making them a flexible solution for a wide range of farming and land maintenance tasks.

- Ease of Maintenance

Regular maintenance of the rotary cutter gearbox is essential for maximizing its lifespan and performance. These gearboxes are designed for ease of maintenance, with accessible grease points and sealed bearings that require minimal lubrication. Additionally, many models include protective features to reduce the ingress of debris and contaminants, ensuring smoother operations and reducing the frequency of repairs or replacements.

- Safety and Protection

Agricultural rotary cutter gearboxes are equipped with safety features such as overload protection, ensuring that the gearbox remains operational under heavy load conditions without risking damage. Furthermore, these gearboxes often come with safety shields or guards to protect operators from moving parts, contributing to a safer work environment.

The Rotary Cutter Gearbox is an essential component in modern agricultural machinery, providing the power and durability needed for a variety of cutting tasks. With their efficient power transfer, robust construction, and ease of maintenance, these gearboxes ensure that rotary cutters operate at peak performance for extended periods, making them a valuable tool for farmers and land managers. Whether used for mowing, land clearing, or vegetation management, the rotary cutter gearbox contributes to improved productivity, reduced operational costs, and enhanced safety in agricultural operations.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX