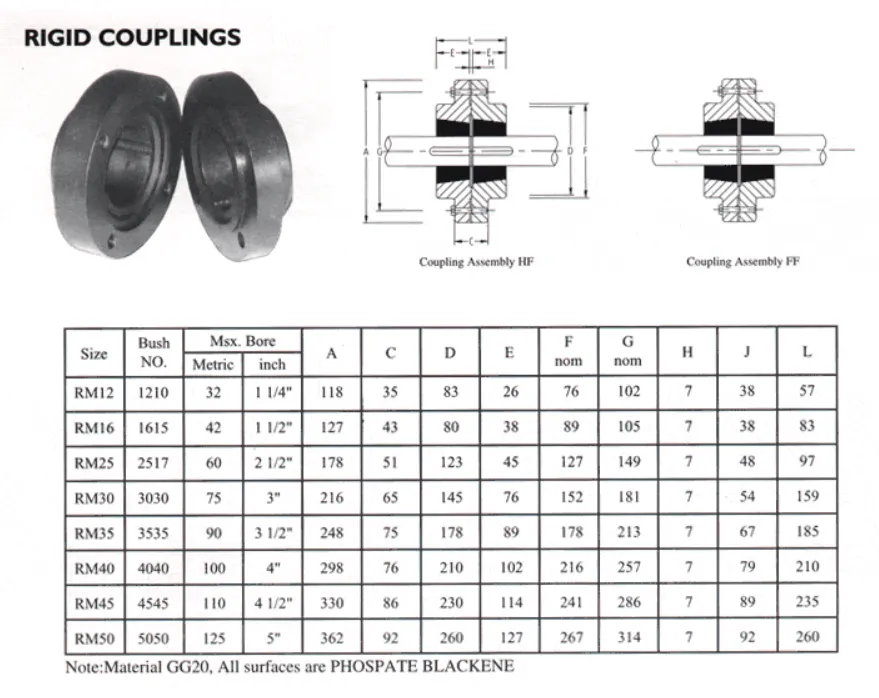

Specifications of Rigid Couplings

Rigid Couplings Features

- Lightweight, ultra-low inertia, and high sensitivity

- Maintenance-free, super oil and corrosion resistance

- Aluminum alloy and stainless steel materials

- Provide fastening bolt type, clip type and separation type

- Models with different hole sizes at both ends are also available in stock

Advantages and Disadvantages of Rigid Couplings

Advantages of Rigid Couplings

Rigid couplings are widely used in low-speed, non-impact applications where shafts exhibit high rigidity and precise alignment due to their simple design, cost-effectiveness, and ability to transmit large torque. A common example is the flange coupling, which consists of two flanged discs connected by bolts. Each disc is mounted to a shaft via a keyed joint, enabling torque and motion transmission between the two shafts.

Key advantages of flange couplings include:

- Simplicity and Affordability: Easy to manufacture, install, and maintain, with low production costs.

- High Torque Capacity: Capable of transmitting substantial torque reliably.

- Precise Alignment: Ensures accurate shaft alignment, making them ideal for high-speed applications or systems requiring strict transmission accuracy.

- Durability: Robust construction minimizes wear under stable load conditions.

However, rigid couplings lack radial, axial, or angular compensation. If shaft alignment is imperfect during operation, it can lead to reduced efficiency, accelerated wear, increased vibration, and noise. To address torque demands, flange couplings may use reamed-hole bolts for all or half of the connections, with the remaining bolts being standard.

Disadvantages of Rigid Couplings

The primary drawback of rigid couplings, such as flange couplings, is their strict requirement for precise shaft alignment. Any relative displacement between the shafts induces additional stress on connected components, worsening operational conditions. This limitation makes them unsuitable for systems with potential misalignment, dynamic loads, or shock absorption needs.

In summary, while rigid couplings excel in simplicity and torque transmission for well-aligned shafts, their inability to compensate for misalignment restricts their use in more dynamic or flexible systems.