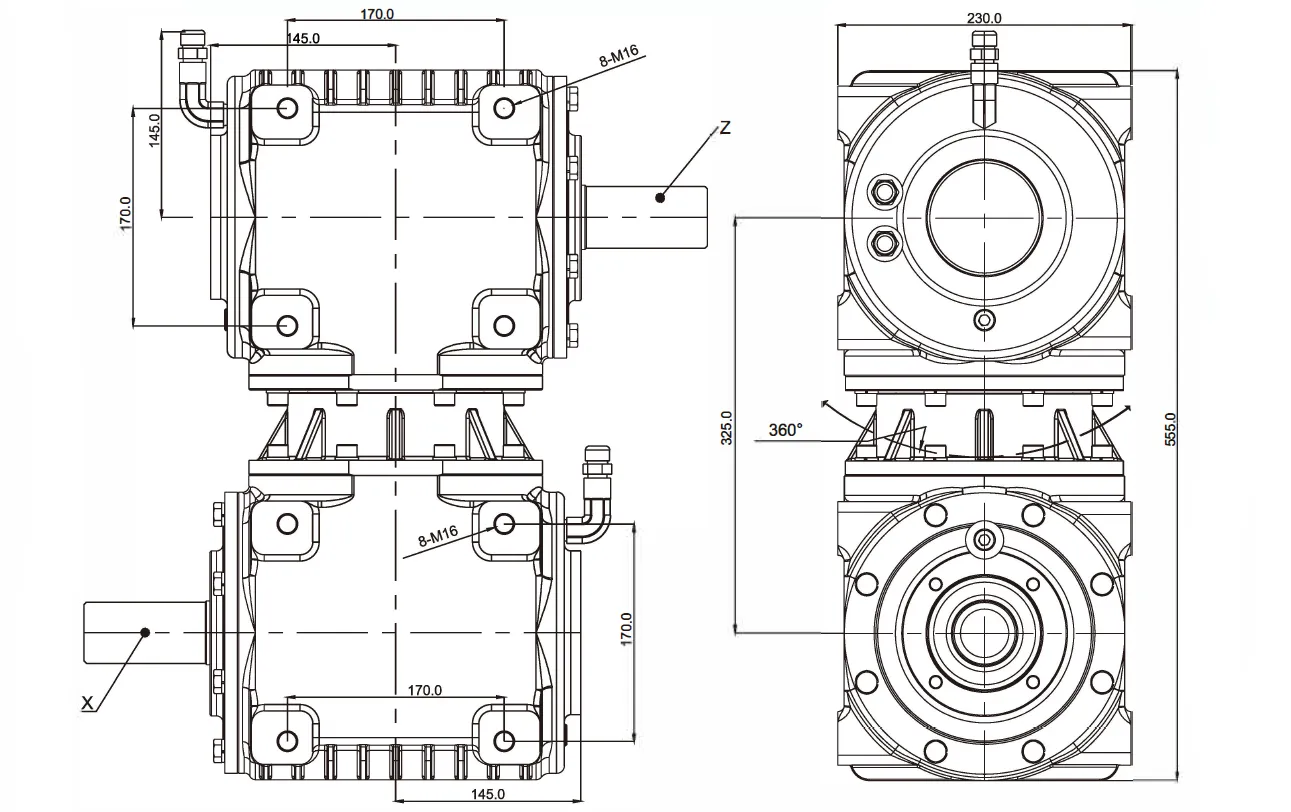

Dimensions of Trailing Mower Gearbox FMP-GC325

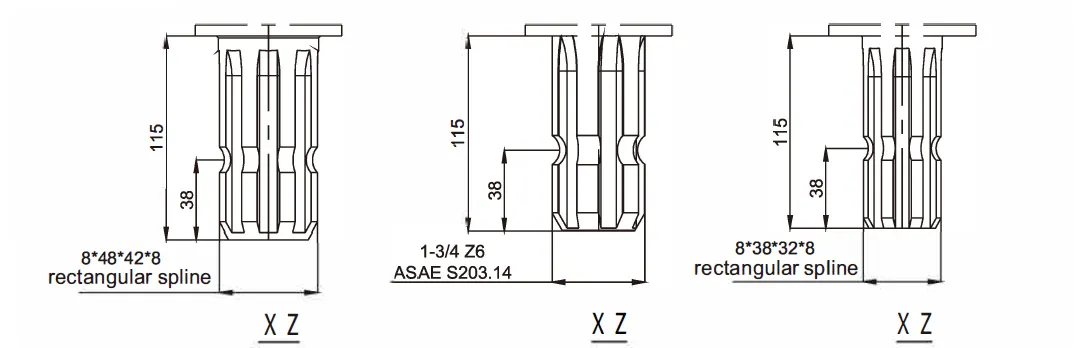

Trailing Mower Gearbox FMP-GC325 Shaft Dimensions

Trailing Mower Gearbox FMP-GC325 Technical Data

| i | Suitable | Rpm input | Rpm output | KW(Nom) | Output torque | Toothing | ||

| r/min | r/min | hp | N.m | |||||

| Speed increase | 1: 1 | Lawn Mower, etc | 540 | 540 | 160 | 1400 | Gleason Helical Teeth |

|

| Remark: If you have any special require feel free let me know, we also accept custom. | ||||||||

Pull-behind Mower Cutter Bar (Trailing Mower Cutter Bar) FMP-GCYB Dimensions

Pull-behind Mower Cutter Bar (Trailing Mower Cutter Bar) FMP-GCYB Technical Data

| Model number | FMP-GCYB06 | FMP-GCYB07 |

| MOP (kw/hp) | 52/70 | 66/90 |

| Work breadth (m) | 2.5 | 3.0 |

| cutter number (n) | 6 | 7 |

| Number of blades (n) | 12 | 14 |

| Rpm input (r/min) | 3000 | |

| Rpm output (r/min) | 3000 | |

| Remark: If you have any special require feel free let me know, we also accept custom. | ||

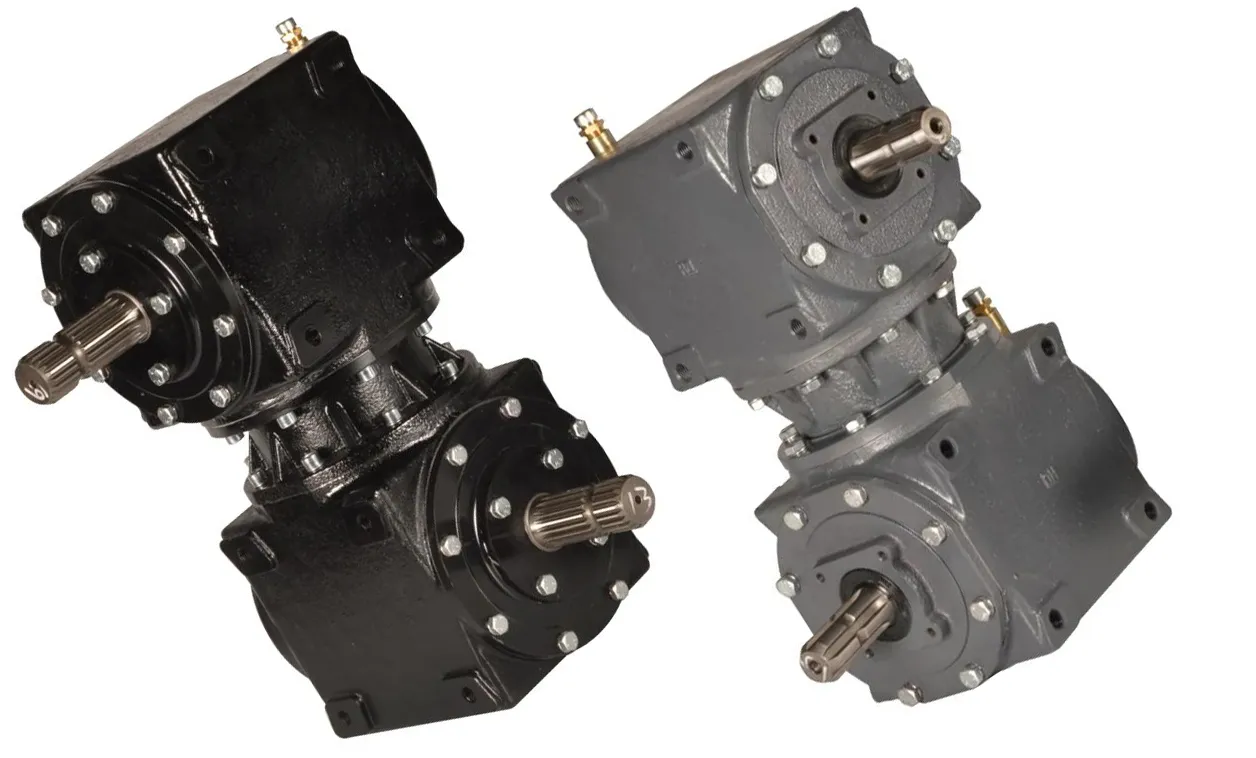

Features of Pull-Behind Mower Gearbox (Trailing Mower Gearbox)

The Pull-behind mower gearbox, also known as the trailing mower gearbox, is an essential component in agricultural and landscaping machinery. It is designed to efficiently transfer power from the tractor’s PTO (Power Take-Off) to the mower’s cutting mechanism, ensuring optimal performance in various mowing and field maintenance applications. Below are the key features of a pull-behind mower gearbox:

- Durable Construction:

- Trailing mower gearboxes are built with robust, high-quality materials to withstand the tough conditions of outdoor use. Their heavy-duty design ensures long-lasting durability, even when subjected to rough terrains and harsh operating environments.

- Efficient Power Transfer:

- These gearboxes are engineered to transfer power from the tractor’s PTO to the mower blades or cutting mechanism efficiently. This ensures that the mower operates smoothly, with minimal loss of power, for consistent cutting performance.

- Smooth Operation:

- Designed for minimal vibration and smooth gear operation, pull-behind mower gearboxes reduce wear and tear on both the gearbox and the mower. This results in improved cutting performance, reduced maintenance needs, and a more comfortable user experience.

- Versatility:

- Pull-behind mower gearboxes are compatible with a wide range of mowing equipment, such as rotary cutters, brush mowers, and lawn mowers. Their versatility allows users to adapt the gearbox to different applications, from mowing pastures to clearing brush and maintaining large grounds.

- Easy Maintenance:

- Many trailing mower gearboxes come equipped with convenient maintenance features, such as oil fill and drain plugs, making oil changes and lubrication easier. Regular maintenance is simplified, ensuring the gearbox remains in optimal condition for longer operational life.

In summary, the pull-behind mower gearbox is designed for durability, efficiency, and ease of use, making it an essential component for a wide variety of mowing and land maintenance tasks. Whether for agriculture, landscaping, or roadside mowing, its reliable performance and user-friendly features make it a valuable tool for achieving efficient, high-quality results.

Common Applications of the FMP-GC325 Trailing Mower Gearbox

The FMP-GC325 trailing mower gearbox is designed for a wide range of agricultural and landscaping applications, providing efficient power transfer and reliable performance. Below are some of the most common applications of the FMP-GC325 gearbox:

- Pasture Mowing:

- The FMP-GC325 gearbox is commonly used in pasture mowing, where it helps manage large expanses of grass. It efficiently powers rotary cutters or mowers to handle dense vegetation and maintain healthy pastureland.

- Field Maintenance:

- This gearbox is ideal for maintaining agricultural fields, including mowing weeds, grass, and undergrowth in crop fields, orchards, and vineyards. Its versatility allows it to be paired with different cutting attachments, adapting to the specific needs of various field types.

- Roadside Mowing:

- In rural and highway maintenance, the FMP-GC325 gearbox powers tow-behind mowers that are used for clearing roadside vegetation, ensuring clear visibility and safe driving conditions. It cuts grass, shrubs, and small trees along roadsides, ditches, and embankments.

- Land Clearing and Brush Cutting:

- The FMP-GC325 is highly effective for land clearing applications, particularly when used with heavy-duty rotary cutters or brush mowers. It is ideal for clearing dense vegetation, brush, and overgrown areas, preparing the land for further agricultural use or construction.

- Large Grounds and Recreational Area Maintenance:

- The FMP-GC325 gearbox is also used for maintaining large open spaces such as parks, golf courses, and sports fields. It can power wide cutting decks, ensuring efficient and uniform grass cutting in expansive areas

By offering dependable and versatile performance, the FMP-GC325 trailing mower gearbox supports various applications, from mowing pastures and clearing land to maintaining large grounds, making it an essential component for agricultural and landscaping equipment.