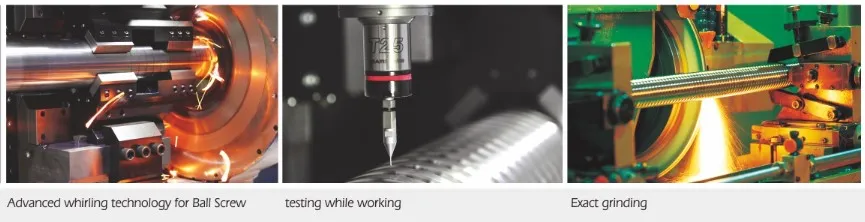

Pneumatic Unclamp Cylinder – Product Introduction

The Pneumatic Unclamp Cylinder is a specialized component designed for use in various industrial applications where automated unclamping is necessary. This type of cylinder utilizes compressed air to provide the force required to release clamping mechanisms, ensuring smooth operation and high efficiency in mechanical systems.

Key Features:

- Pneumatic Actuation: The cylinder operates using compressed air, offering a clean, efficient, and cost-effective solution compared to hydraulic or manual systems.

- High Force Output: Engineered to generate significant force for unclamping actions, suitable for heavy-duty industrial applications.

- Durability: Constructed from high-quality materials for extended service life, even under demanding working conditions.

- Precision Control: Features precise control of clamping and unclamping actions, enhancing the accuracy and reliability of your automation processes.

- Compact Design: Optimized for space efficiency, making it ideal for use in environments with limited installation space.

- Easy Integration: Compatible with a wide range of machinery, offering seamless integration into existing systems for easy upgrades and replacements.

- Corrosion Resistance: Built to withstand harsh environments, with anti-corrosion treatments ensuring reliability in challenging industrial conditions.

Advantages:

- Increased Efficiency: By automating the unclamping process, operational cycles are shortened, leading to higher throughput and reduced downtime.

- Reduced Labor: Less manual intervention is required, minimizing the risk of errors and improving workplace safety.

- Energy Saving: Air-driven cylinders typically consume less energy than hydraulic systems, offering cost-effective operation over time.

- Customizable: Available in various sizes, stroke lengths, and pressure ratings to suit different industrial needs and applications.

The Pneumatic Unclamp Cylinder is an essential component for businesses looking to enhance their operational efficiency, reduce manual labor, and ensure a high level of precision in automated processes.

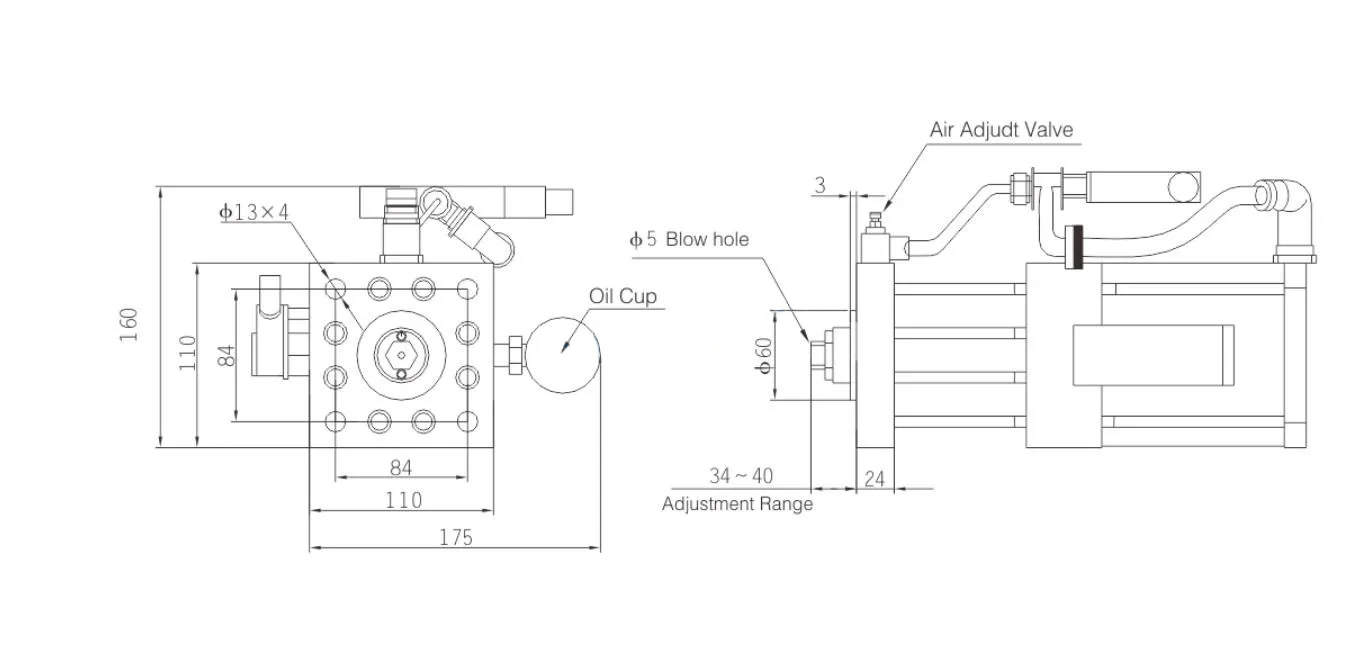

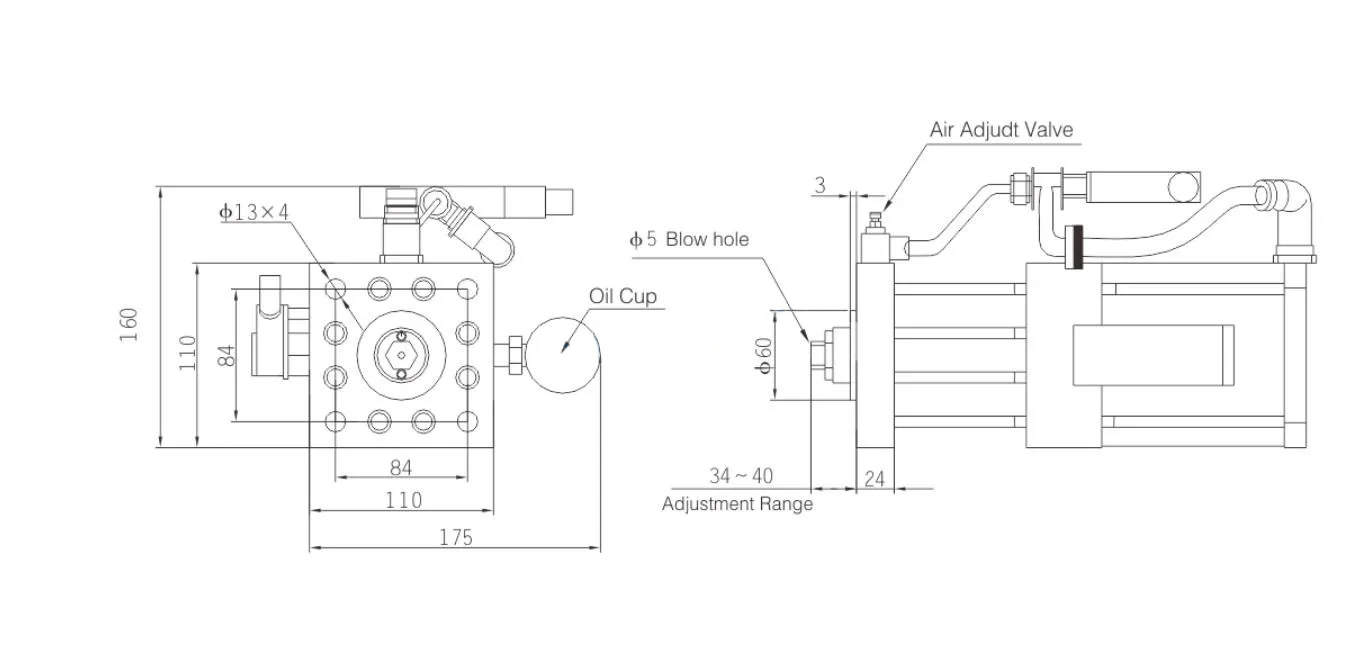

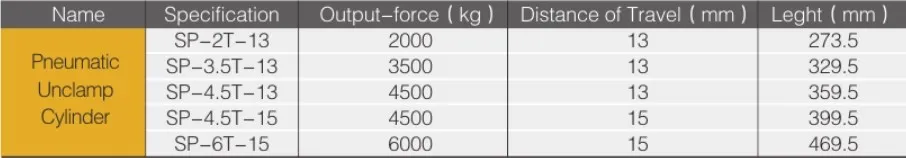

Model List

NOTE:

1. The pneumatic unclamp cylinder can be installed vertical and horizontal, the oil cup must be upward.

2. The input gas source must be treated by the gas source triplet. For dry and clean air, the minimum pressure is 6kgf/cm².

3. The minimum safe oil content in the oil cup is 1/5, and the highest oil content is 4/5.

Types of Pneumatic Unclamp Cylinders

Pneumatic unclamp cylinders come in various types, each designed for specific applications and operational requirements. Here are the most common types:

1. Single-Acting Pneumatic Unclamp Cylinder

- Description: A single-acting pneumatic unclamp cylinder operates with air pressure applied only on one side of the piston. The return stroke is usually achieved via a spring or external force.

- Application: Common in simpler systems where unclamping force is required in one direction, and the return stroke can be assisted by a spring.

- Advantages:

- Cost-effective

- Simple design and easy to maintain

- Requires less air consumption

2. Double-Acting Pneumatic Unclamp Cylinder

- Description: In a double-acting pneumatic unclamp cylinder, air pressure is applied on both sides of the piston for both clamping and unclamping actions, allowing for more control over the cylinder’s motion.

- Application: Ideal for applications requiring higher force and more precise control over the unclamping process, such as in automated production lines or robotic systems.

- Advantages:

- Higher force and faster response time

- Precise control over both clamping and unclamping actions

- Can be used for more complex applications

3. Rotary Pneumatic Unclamp Cylinder

- Description: This type of cylinder is designed for applications where rotational movement is required in addition to linear motion. It features a rotary actuator combined with a pneumatic unclamp mechanism.

- Application: Often used in automated fixtures or machines where the clamping system needs to rotate before or after unclamping.

- Advantages:

- Offers both rotational and linear motion

- Can perform complex tasks such as turning parts or fixtures after unclamping

4. Compact Pneumatic Unclamp Cylinder

- Description: These cylinders have a smaller, more compact design while maintaining high force output. They are suitable for tight spaces where traditional cylinders may not fit.

- Application: Used in applications where space is limited but strong unclamping force is still required, such as in small-scale automation systems or machinery with constrained installation spaces.

- Advantages:

- Space-saving design

- High performance in compact packages

5. Double Rod Pneumatic Unclamp Cylinder

- Description: This type of cylinder features rods on both sides of the piston, allowing for a more balanced force distribution and a more uniform movement during unclamping and clamping.

- Application: Ideal for applications that require high stability, accuracy, and balanced motion, such as in high-precision machinery and robotics.

- Advantages:

- Greater stability and load distribution

- Suitable for high-precision applications

Each type of Pneumatic Unclamp Cylinder serves a specific need depending on the application requirements, space constraints, force demands, and precision needed. Selecting the right type of pneumatic unclamp cylinder ensures optimal performance and efficiency in automated and mechanical systems.

About FMP

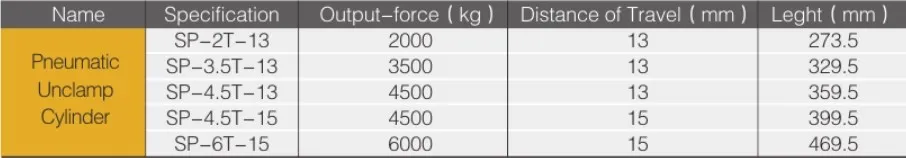

FMP is a professional manufacturer specializing in the production of mechanical components. Our main products include spiral bevel worm gear reducers, sprockets, taper bushings, gear racks, couplings, and other transmission parts. With a strong export focus, over 65% of our products are shipped to European markets, including Germany, the UK, and France, achieving an annual export volume of $18 million. Our total annual production value reaches 200 million RMB.

All FMP products are manufactured in compliance with international, European, and U.S. industrial standards. We utilize precision and high-quality machining equipment, implement well-planned production processes, and adhere to an efficient and flexible management system. Our comprehensive quality management system ensures excellent product quality and competitive pricing.

FMP operates on the core principles of “Quality: the foundation of business survival, Integrity: the driving force behind business development, Service: the source of business growth, and Affordability: the key to business success.” We welcome both domestic and international customers and look forward to collaborating for mutual growth and success.

Author: CX