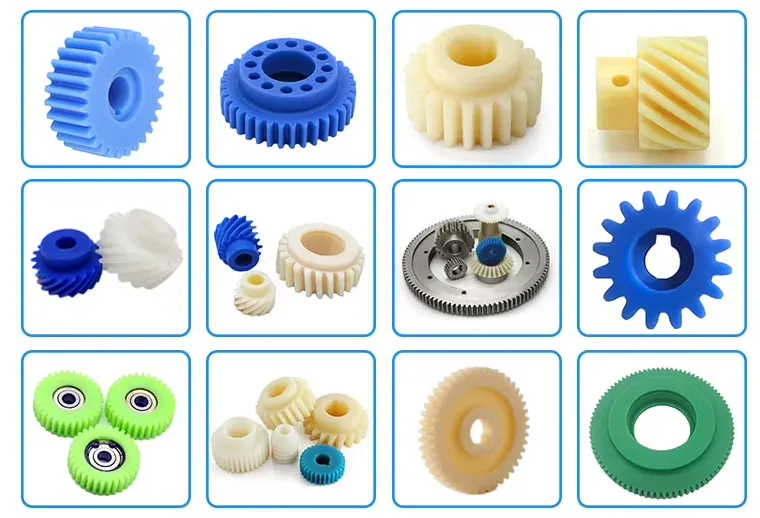

Plastic Worm Gears: Durable, Customizable Solutions from FMP Company

Plastic worm gears are vital components in modern machinery, offering a unique combination of durability, versatility, and efficiency. At FMP Company, we specialize in manufacturing high-quality plastic worm gears designed to meet the diverse needs of industries across Italy and beyond. Whether you require standard models or bespoke solutions, our expertise ensures you receive reliable, tailored products.

Why Choose Plastic Worm Gears?

Plastic worm gears provide distinct benefits over their metal counterparts, making them a preferred choice in various applications:

- Lightweight Design: Significantly lighter than metal gears, plastic worm gears reduce machinery weight, enhancing energy efficiency.

- Rust-Proof Durability: Resistant to corrosion, they excel in humid or harsh environments, ensuring long-term performance.

- Low Noise Operation: Their smooth operation minimizes noise, ideal for applications requiring quiet performance, such as medical devices or consumer electronics.

- Cost-Effective Production: Injection molding enables affordable, large-scale manufacturing without compromising quality.

- Self-Lubricating Properties: Made from materials like polyacetal (POM) and MC Nylon, they often operate without additional lubrication, reducing maintenance needs.

In Italy, industries such as food production, consumer electronics, and medical equipment manufacturing increasingly demand these qualities. The lightweight and rust-proof nature of plastic worm gears aligns perfectly with the needs of Italian businesses seeking efficient, reliable solutions.

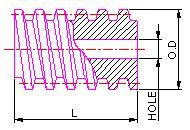

Specification

|

|

| Type | Worm |

| Module | M0.2 – M2.0 |

| Material | Polyacetal (POM) / Nylon |

| Bore | Ø1.40mm/ Ø1.90mm |

| Outer Diameter | Ø4.0mm/ Ø5.0mm/ Ø6.0mm (Flexible) |

| Length | 6.0mm/ 8.5mm/ 10.0mm (Flexible) |

|

|

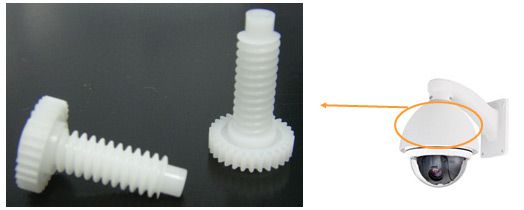

| Item | M0.4*30T Gear+Worm |

| Material | TEPCON_M90-10 |

| Module | M0.4 |

| No. of Teeth | 30T / 1T |

| Weight | 0.75g / pcs |

| Application | IP Camera, monitor, etc. |

|

|

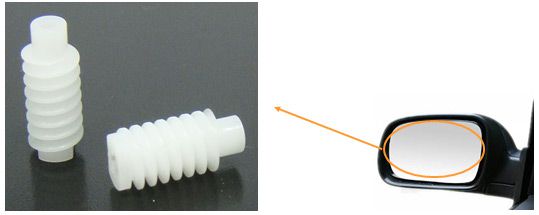

| Item | M0.4 RH Worm |

| Material | TEPCON_M90-10 |

| Module | M0.4 |

| No. of Teeth | 1T (RH) |

| Weight | 0.22g / pcs |

| Application | Applies in the gearbox of adjusting automotive rearview mirror. |

|

|

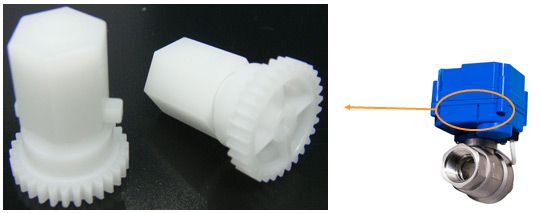

| Item | Gear Screw & Screw Nut |

| Material | ODM |

| Module | ODM |

| No. of Teeth | ODM |

| Weight | ODM |

| Application | Applies in the gearbox of adjusting water valve. |

FMP Company’s Plastic Worm Gears: Quality and Customization

At FMP Company, we pride ourselves on delivering a wide range of plastic worm gears to suit various applications:

- Diverse Product Range: Our catalog includes standard plastic worm gears with modules ranging from 0.5 to 3 and speed ratios from 10 to 50, crafted from high-quality MC Nylon or POM.

- Customization Services: We understand that every project has unique requirements. Our team offers custom plastic worm gears tailored to your specifications, ensuring optimal performance for your specific application.

- Not Finding Your Model?: If the gear you need isn’t listed, don’t worry—it may not yet be uploaded to our product list. Simply email us at info@fmpcomponents.it with your requirements, and our engineers will respond within 24 hours to assist you.

Our commitment to quality and flexibility makes FMP Company a trusted partner for Italian industries seeking durable plastic gears.

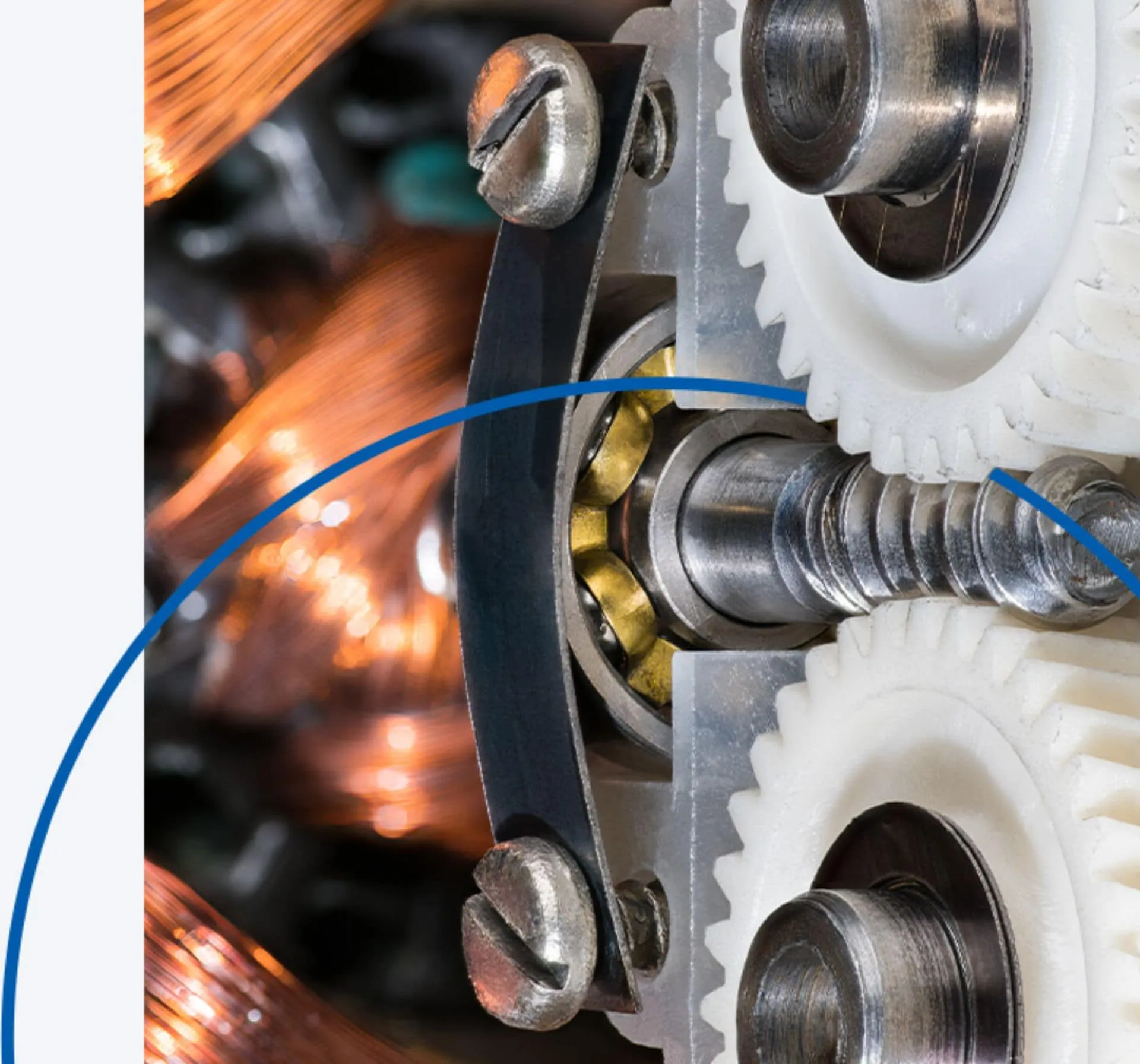

Materials and Manufacturing Excellence

The performance of plastic worm gears hinges on the materials and processes used in their creation:

- Premium Materials: We use engineering plastics like POM (polyacetal) and MC Nylon, known for their strength, wear resistance, and ability to function without lubrication. For demanding applications with temperature fluctuations or heavy loads, we can integrate metal hubs (e.g., S45C or stainless steel) for added stability.

- Advanced Manufacturing: Our production combines precision injection molding with expert machining, ensuring each gear meets rigorous quality standards. This process guarantees durability, dimensional accuracy, and cost-effectiveness.

These capabilities allow us to produce plastic worm gears that excel in Italy’s diverse industrial landscape, from coastal food processing plants to high-tech electronics manufacturers.

|

|

Applications in Italy

Plastic worm gears from FMP Company have proven their value across Italian markets:

- Food Production: In machinery requiring hygiene and moisture resistance, our rust-proof gears ensure reliable operation without contamination risks.

- Consumer Electronics: Their lightweight and quiet performance enhance devices like printers and cameras, meeting Italy’s demand for innovative technology.

- Medical Equipment: The low noise and durability of our gears support precision instruments, a growing sector in Italy’s healthcare industry.