Plastic Rack and Pinion: Precision and Durability for Italian Industries

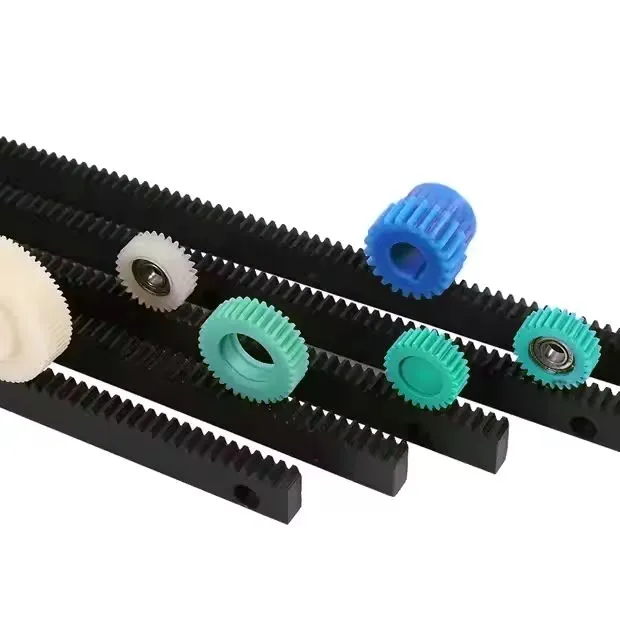

In mechanical engineering, plastic rack and pinion systems are a reliable solution for converting rotary motion to linear motion (or vice versa). Consisting of a linear rack and meshing pinions, the mechanism is used across a wide range of industries for its precision, durability and versatility. In Italy, from the industrial heart of Milan to the manufacturing hub of Bologna, plastic rack and pinion systems have become an integral part of applications such as automation, CNC machine tools and steering systems.

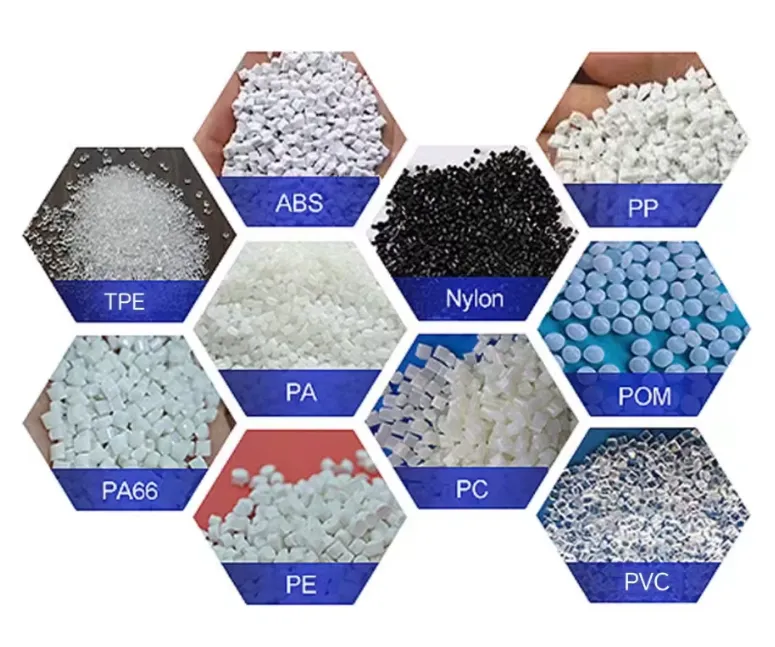

Made from high-performance materials such as nylon and polyoxymethylene, plastic rack and pinion systems offer significant advantages over metal rack and pinion systems. These advantages include lower noise, greater wear resistance and self-lubricating properties, making them ideal for environments with high maintenance requirements. Whether in an artistic workshop in Florence or in the maritime industry in Venice, plastic gears offer cost-effective, high-quality solutions to meet a variety of needs.

Benefits of Plastic Rack and Pinion

Durability and Wear Resistance

Plastic gear racks, particularly those made from nylon plastic or acetal plastic, are engineered for longevity. Their inherent wear resistance ensures consistent performance in demanding applications, such as elevators and rail systems across Italian cities like Milan and Bologna. Unlike metal gears, plastic racks resist corrosion and require minimal lubrication, reducing maintenance costs.

Noise Reduction

In environments where noise control is critical, such as packaging machines in Florence or automation systems in Venice, plastic rack and pinion systems excel. The polymers used dampen vibrations, resulting in quieter operation compared to metal alternatives, enhancing workplace safety and comfort.

Lightweight and Cost-Effective

Plastic gears are significantly lighter than metal, making them ideal for applications requiring reduced weight, such as stair lifts or pneumatic actuators in Bologna. Their cost-effectiveness also appeals to businesses seeking high-quality solutions without breaking the budget, a priority for industries throughout Italy.

Self-Lubricating Properties

The materials in the FMP product range are self-lubricating and do not require frequent lubrication, a property that is particularly important in the dusty or dirty environments common in the Milan and Venice manufacturing plants, where traditional lubrication methods are not practical.

Applications of Plastic Rack and Pinion

Plastic rack and pinion systems are highly versatile, serving a wide range of industries with reliable performance:

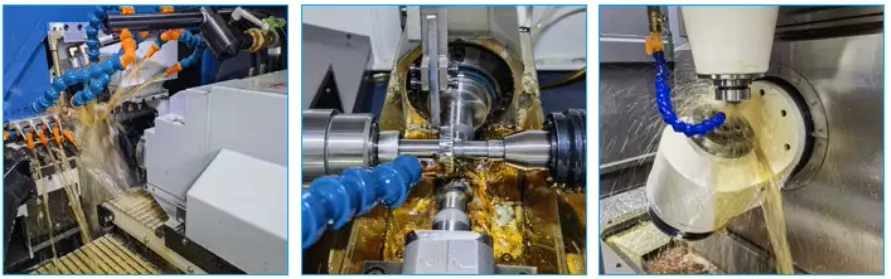

- Automation and CNC Machines: Plastic gear racks deliver precise linear motion in CNC machines, enhancing productivity in advanced manufacturing environments.

- Steering Mechanisms: From small vehicles to industrial equipment, plastic racks provide lightweight, responsive steering solutions.

- Elevators and Lifting Systems: Plastic gear racks ensure durable and efficient operation in elevators and lifting systems, where space and reliability are critical.

- Packaging and Positioning Systems: In packaging machines, plastic racks offer smooth and accurate motion control, supporting high-precision operations.

These applications demonstrate the adaptability of plastic rack and pinion systems, meeting diverse industrial demands with precision and efficiency.

Why Choose Plastic Over Metal?

While metal gear racks are robust, plastic racks offer unique advantages that align with modern industrial needs:

- Corrosion Resistance: Plastic racks withstand moisture without rusting, making them ideal for humid or challenging environments.

- Customization: Plastic racks can be tailored to specific sizes and modules, meeting bespoke requirements for innovative designs.

- Eco-Friendly: Plastic gears, especially those made from recyclable materials, support sustainable practices, appealing to environmentally conscious businesses.

For OEMs and metal replacement needs, plastic rack and pinion systems deliver performance matching industry standards, ensuring seamless integration into existing setups.