Plastic Planetary Gears: Precision and Efficiency

Plastic planetary gears are a cornerstone of modern mechanical engineering, providing a compact, efficient and versatile solution for torque transmission and motion control. Consisting of a central sun gear, multiple planetary gears and an outer ring gear, these gear systems are designed to provide high reduction ratios in a small footprint. In Italy, urban industries rely on plastic planetary gears because of their lightweight, low noise and cost-effectiveness, making them ideal for a wide range of applications from robotics to automotive systems.

Made from high-quality materials such as nylon, polyoxymethylene and other advanced plastics, plastic planetary gears offer exceptional durability and performance. Unlike traditional metal gears, these plastic systems offer unique advantages that meet the demands of modern technology, especially in environments where weight, noise and corrosion resistance are critical.

Advantages of Plastic Planetary Gears

Lightweight and Compact Design

One of the standout features of plastic planetary gears is their lightweight construction. By using plastic for the outer ring gear and combining it with sintered metal for inner components, these gears significantly reduce weight compared to metal alternatives. This makes them ideal for applications where minimizing weight is critical, such as portable devices or space-constrained equipment.

Low Noise and Vibration

Plastic planetary gears excel in reducing noise and vibration, thanks to the damping properties of plastic materials. This characteristic is particularly valuable in sectors like medical equipment and consumer electronics, where quiet operation enhances user experience and workplace safety.

Corrosion Resistance

Unlike metal gears, plastic planetary gears resist corrosion without requiring lubrication. This makes them suitable for harsh environments, such as chemical processing or humid conditions, ensuring reliable performance across various industries.

Cost-Effective Solution

Plastic gears are generally more affordable to produce than metal gears, offering a cost-effective option for manufacturers. Their lower production costs do not compromise quality, making them a smart choice for budget-conscious businesses seeking high performance.

Customization and Flexibility

Plastic planetary gears can be molded into complex shapes, allowing for tailored designs to meet specific requirements. Whether adjusting gear ratios, sizes, or torque capacities, this flexibility optimizes performance for unique applications.

Non-Magnetic Properties

The non-magnetic nature of plastic gears is a key advantage in sensitive applications, such as medical imaging devices or electronic equipment. This feature ensures minimal interference, supporting precision in high-tech industries.

Applications of Plastic Planetary Gears

Plastic planetary gears are integral to numerous industries, providing reliable motion control and torque transmission:

- Robotics: Plastic planetary gears drive precise movements in robotic systems, enhancing efficiency in automation applications.

- Automotive: Lightweight gears support compact designs in electric vehicle components, contributing to innovative automotive solutions.

- Home Appliances: Plastic gears ensure smooth operation in appliances like washing machines and blenders, delivering consistent performance.

- Medical Equipment: Corrosion-resistant gears are vital for medical devices, where reliability and durability are essential.

- Office Equipment: From printers to copiers, plastic planetary gears provide dependable performance in commercial applications.

These applications highlight the versatility of plastic planetary gears, meeting diverse industrial needs with precision and durability.

Limitations of Plastic Planetary Gears

While plastic planetary gears offer numerous benefits, they have some limitations compared to metal gears:

- Load Capacity: Plastic gears may not handle extremely high torque loads as effectively as metal gears, requiring careful application assessment.

- Heat Resistance: Plastic gears can deform under high temperatures, making them less suitable for extreme thermal environments.

- Precision: Metal gears often provide tighter tolerances, which may be preferred for ultra-precise applications.

For most applications, however, plastic planetary gears strike an excellent balance of performance, cost, and practicality, especially when customized to specific needs.

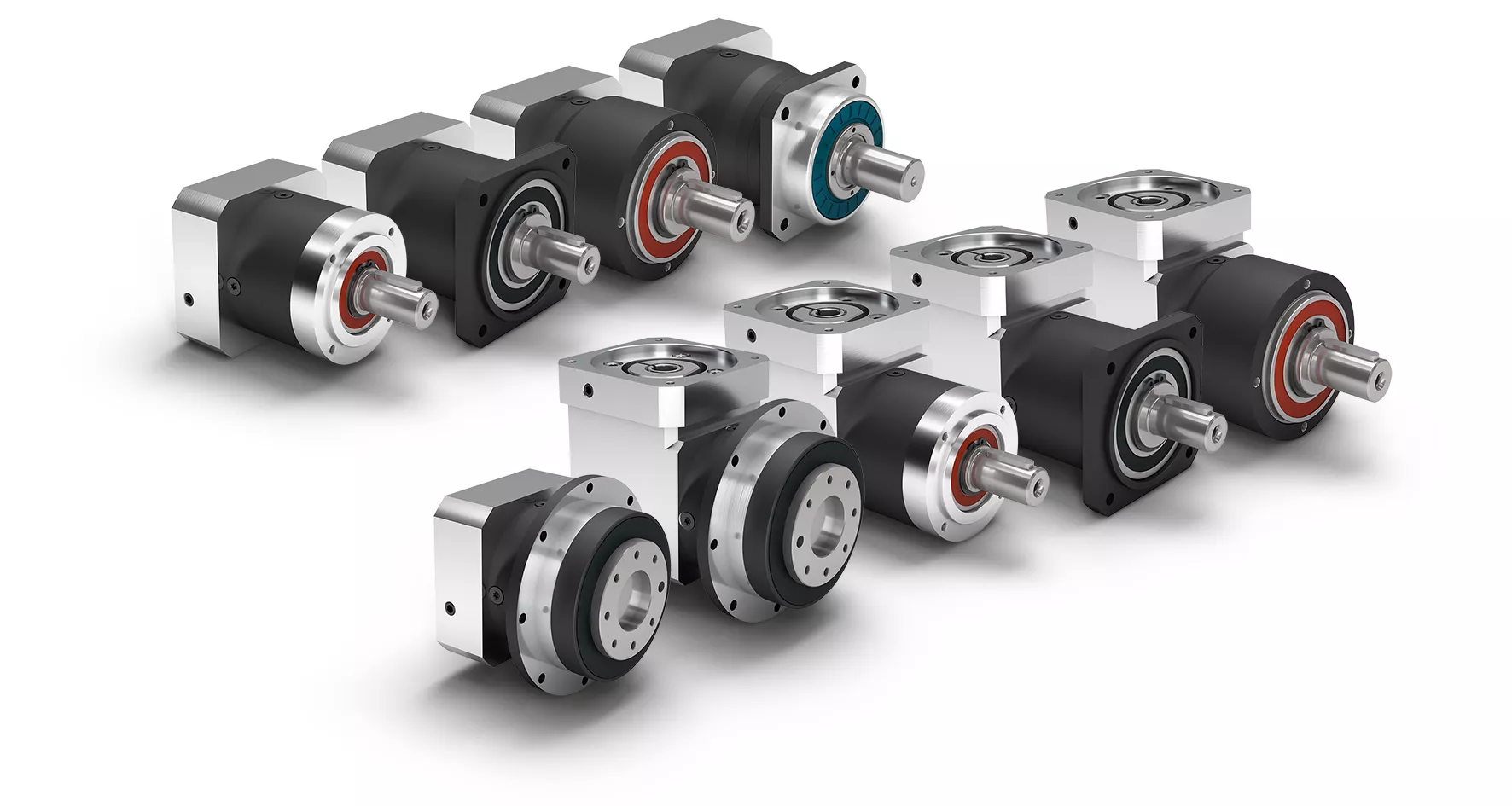

Plastic Planetary Gears vs. Plastic Planetary Gearboxes

Plastic planetary gears are the core components of plastic planetary gearboxes, which integrate the gears into a complete system with a motor, casing, and carrier plates. While the gears themselves—comprising the sun, planet, and ring gears—handle torque transmission and motion control, the gearbox provides a compact, ready-to-use solution that enhances efficiency and simplifies integration. In essence, the gears are the functional heart of the gearbox, designed for specific performance metrics, while the gearbox offers a plug-and-play system for various industrial applications. Whether you need standalone gears or a full gearbox, both leverage the lightweight and low-noise benefits of plastic materials.

|

|

|

|

|

|

Related Products – Planetary Gearbox

At FMP, we are proud to offer a comprehensive range of plastic planetary gears and planetary gearboxes, designed to meet diverse industrial needs. Our plastic planetary gears deliver precision and efficiency for torque transmission, while our planetary gearboxes integrate these gears with motors, casings, and carrier plates to provide compact, ready-to-use solutions. Both product lines are crafted from high-quality materials like nylon and acetal, ensuring lightweight construction, low noise, and durability. Whether you require standalone gears or complete gearbox systems, FMP provides customizable, high-performance solutions tailored to your specific applications.

Please contact us for more products

About FMP: Your Trusted Partner for Plastic Planetary Gears in Italy

At FMP, we specialize in manufacturing a wide range of plastic planetary gears and related products, serving industries in Milan, Venice, Florence, and Bologna. Our offerings include standard and custom gears made from premium materials like nylon and acetal, designed to deliver high efficiency, durability, and precision. We pride ourselves on meeting the unique needs of our clients, whether for robotics, automotive, or medical applications.

FMP also offers customization services, allowing us to tailor plastic planetary gears to your exact specifications. If you don’t find the model you need in our product listings, it may not yet be uploaded. Simply email us with your requirements, and our dedicated engineers will respond within 24 hours with a solution designed to meet your needs. Trust FMP to deliver innovative, high-quality plastic gear solutions that drive success for your projects across Italy.