Plastic Gear Sets: Precision and Versatility for Mechanical Applications

Plastic gear sets are essential components in modern mechanical systems, offering lightweight, durable, and cost-effective solutions for power transmission. These sets typically include gears of varying sizes and tooth counts, designed to work seamlessly together in applications ranging from robotics to consumer electronics. In Italy’s innovation-driven cities like Milan, Venice, Florence, and Bologna, plastic gear sets are widely used for their rust-proof nature, low maintenance, and ability to operate without lubrication. Crafted from high-quality engineering plastics, they provide reliable performance across diverse industries.

Advantages of Plastic Gear Sets

Plastic gear sets offer several benefits that make them a preferred choice over metal alternatives, especially in Italy’s design and manufacturing hubs:

- Lightweight: Made from materials like polyacetal (POM), nylon, and Duracon, plastic gears reduce system weight, ideal for applications in Florence’s robotics labs or Venice’s automation sectors.

- Corrosion Resistance: Unlike metal gears, plastic gear sets are rust-proof, ensuring longevity in humid environments or chemical-exposed settings common in Bologna’s industrial zones.

- Low Noise: Plastic gears operate quietly, making them suitable for consumer electronics and medical devices produced in Milan’s tech-driven markets.

- Cost-Effective Production: Injection molding enables high-volume production at low costs, supporting scalable manufacturing for Italian businesses.

- No Lubrication Needed: Many plastic gears, such as those made from nylon, can pair with metal gears without lubrication, reducing maintenance costs.

Despite their lower strength compared to metal, careful material selection and design mitigate these limitations, ensuring reliable performance for specific loads and conditions.

Materials Used in Plastic Gear Sets

The performance of a plastic gear set depends heavily on its material. Common options include:

- Polyacetal (POM): Known for low friction and high wear resistance, ideal for precision gears in automotive and industrial applications.

- Nylon (MC901): Offers excellent tensile strength and elasticity, perfect for heavy-duty gear sets in Bologna’s machinery sector.

- Duracon: A cost-effective option for injection-molded gears, suitable for light-load applications like DIY projects in Florence.

- PEEK and U-PE: Used in high-performance settings requiring chemical resistance, often seen in Milan’s medical device manufacturing.

- Reinforced Variants: Gears with stainless steel or brass hubs (e.g., acetal with SUS303 cores) enhance durability for demanding environments.

These materials allow Italian manufacturers to tailor gear sets to specific needs, balancing strength, weight, and environmental resistance.

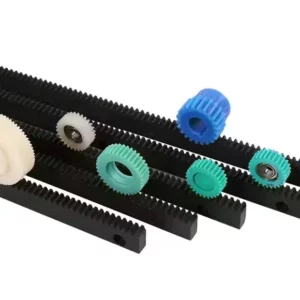

Types of Gears in Plastic Gear Sets

Plastic gear sets typically include a variety of gear types to suit different mechanical requirements:

- Spur Gears: Simple and efficient, used for straightforward power transmission in consumer products.

- Bevel Gears: Facilitate angular motion, common in robotics and automotive systems in Venice.

- Miter Gears: Enable 90-degree power transfer, ideal for compact machinery.

- Worm Wheels and Worms: Provide high gear ratios for precise control, used in Milan’s automation equipment.

- Racks: Convert rotational motion to linear, supporting applications like CNC machines in Bologna.

Modules range from 0.5 to 4, with tooth finishes cut or injection-molded to achieve grades like JIS N9-N12, ensuring compatibility with diverse systems.

Applications Across Industries

Plastic gear sets are versatile, serving a wide range of industries in Italy’s vibrant economy:

- Robotics: Lightweight gears enable agile movement in prototypes developed in Florence’s tech hubs.

- Consumer Electronics: Quiet, durable gears power devices like printers and cameras, popular in Milan’s design studios.

- Medical Equipment: Non-corrosive gears ensure reliability in diagnostic tools manufactured in Bologna.

- Automotive: Plastic gears reduce weight in auxiliary systems, supporting Venice’s automotive suppliers.

- DIY and Education: Affordable gear sets inspire innovation in classrooms and maker spaces across Italy.

Their adaptability makes them a cornerstone of both prototyping and production in Italy’s industrial landscape.

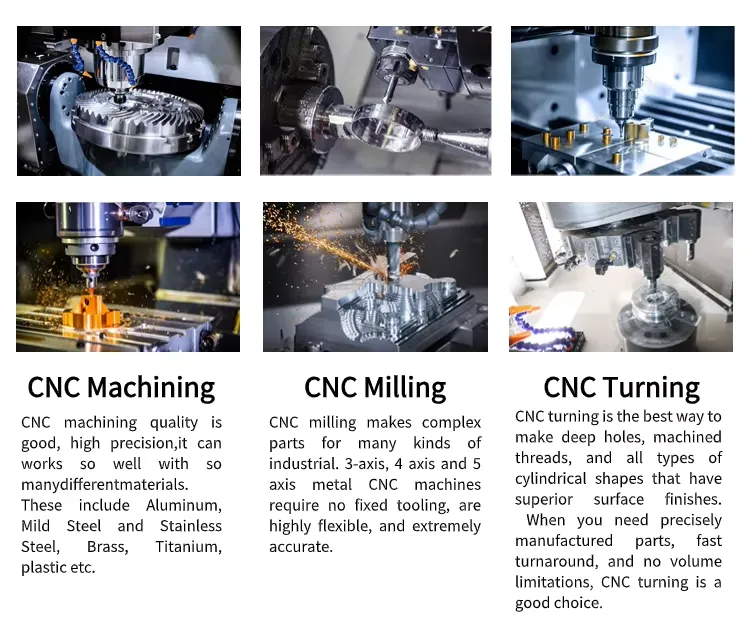

About FMP: Your Trusted Source for Plastic Gears

At FMP, we pride ourselves on being a leading manufacturer of plastic gears, serving businesses in Milan, Venice, Florence, and Bologna. Our extensive range includes spur, bevel, miter, worm, and rack gears, crafted with precision to meet the needs of industries from robotics to automotive. We specialize in:

- Comprehensive Gear Solutions: Offering a variety of plastic gear types to suit any mechanical application.

- Custom Manufacturing: We accept fully customized orders, designing gears to your exact specifications, whether for prototypes or high-volume production.

- Rapid Support: Can’t find the gear model you need in our catalog? It’s likely we haven’t uploaded it yet. Email us your requirements, and our engineers will respond within 24 hours with a tailored solution.

Based in Italy’s manufacturing heartland, FMP combines cutting-edge injection molding with a commitment to quality, ensuring your projects succeed. Contact us today at info@fmpcomponents.it to explore how our plastic gear sets can drive your innovation forward.