In the bushing pin coupling, there is an intermediate ring between the elastic elements. This ring is floating and connected to the end disc aligned by a pin. The coupling is transmitted to the other half of the coupling via the elastic element mounted on the pin, while the pin and the half of the coupling are non-rigidly connected, which can smoothly load and significantly reduce lateral forces.

The advantage of this coupling is that it can easily cooperate with slightly misaligned shafts and adds a certain flexibility to help absorb vibrations and shocks. This coupling is particularly suitable for situations where there is axial, radial or angular misalignment and is a flexible coupling device.

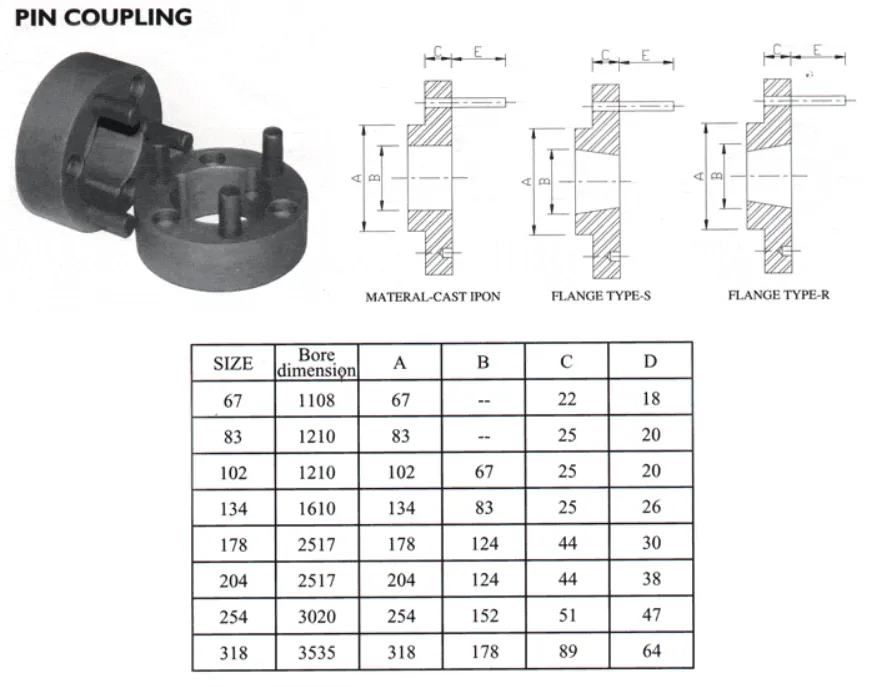

Dimensions of Pin Couplings

Features of Pin Couplings

1. Cost-Effective & User-Friendly Design

- Low Cost: Economical solution for torque transmission between shafts.

- Simple Assembly: Streamlined installation process minimizes downtime.

- Material Versatility: Typically constructed from metal or rubber, with specialized variants available for enhanced joint strength.

2. Mechanical Advantages

- Misalignment Tolerance: Capable of accommodating angular, parallel, and axial shaft misalignments, reducing stress on connected equipment.

- Force Resistance: Leverages friction on contact surfaces to support large forces, effectively dampening vibrations and extending machinery lifespan.

3. Technical Design Considerations

- Three-Pin Coupling Optimization:

- Friction Management: Interface plane designed for higher friction, while pin edges maintain low friction to prevent asymmetric bending.

- Dimpled Friction Plates: Optional feature to enhance frictional properties and torque transmission efficiency.

- Preload Precision: Bolts must be torqued to at least 10% of the final load to ensure secure pin-to-interface contact and optimal performance.

4. Fail-Safe & Protective Role

- Acts as a mechanical safeguard, absorbing shock loads and preventing damage to critical components under overload conditions.

5. Customization & Adaptability

- Specialized Configurations: Available in tailored designs to meet specific operational demands, such as high-torque or corrosive environments.

Pin couplings offer a practical balance of simplicity, resilience, and adaptability, making them ideal for systems requiring cost-effective torque transmission with built-in misalignment and vibration management.