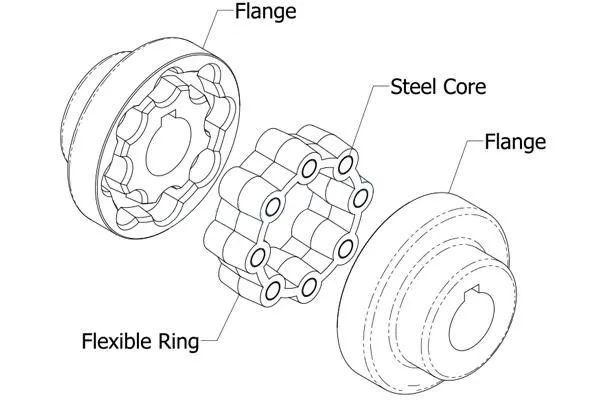

The MH series is a flexible coupling device constructed of synthetic rubber with two similar cast iron bodies. The high-quality cast iron flanges are mainly used for power transmission and protect the flexible rubber. Its elastic rubber provides excellent durability and quality coupling performance. The MH coupling consists of two flanges and elastic rings, which are able to compensate for various types of shaft misalignment. The elastic ring is made of synthetic rubber and is reinforced with a steel core inside to increase the reliability of the coupling and the maximum operating speed. The damping properties of the rubber are able to absorb and suppress torsional vibrations and work effectively in a temperature range of -40 to +100°C. In addition, the rubber is resistant to oil, dirt, grease, moisture, ozone and many chemical solvents.

Construction of MH Couplings

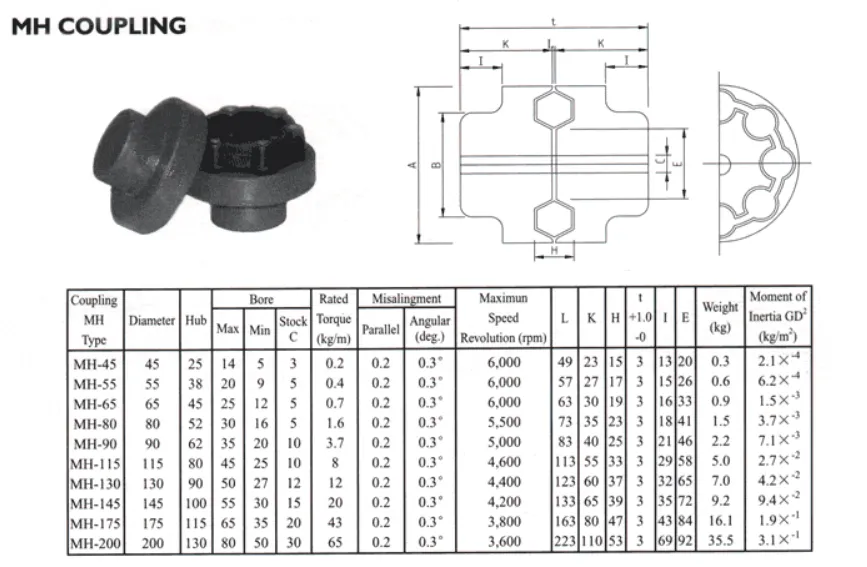

MH Coupling Specifications

Applications of MH Couplings

MH couplings, depending on their specific design and industry context, can refer to various types of couplings, each with distinct applications. Below is a structured overview of potential applications based on common interpretations:

General Industrial Machinery

- Pumps and Compressors: Connect motors to shafts, accommodating misalignment and reducing vibration transmission.

- Conveyor Systems: Link drive motors to conveyors, allowing for alignment shifts due to operational wear.

- Fans and Blowers: Dampen vibrations and handle thermal expansion in HVAC systems.

Precision Motion Control

- Robotics: High-precision bellows or helical couplings (e.g., R+W MH series) ensure zero backlash in servo-driven joints.

- CNC Machines: Transmit precise motion from motors to spindles or lead screws.

- Semiconductor Manufacturing: Used in cleanroom equipment for accurate positioning.

Hydraulic and Fluid Systems

- Quick-Disconnect Couplings: Enable fast, leak-free connections in hydraulic machinery (construction, agriculture).

- Chemical Plants: Metal hose couplings handle corrosive fluids and high temperatures.

High-Temperature/Corrosive Environments

- Exhaust Systems: Automotive/marine applications using heat-resistant metal hose couplings.

- Oil and Gas: Flexible couplings in pipelines to manage thermal expansion and vibration.

Marine and Offshore

- Propulsion Systems: Accommodate shaft misalignment caused by hull flexing.

- Deck Machinery: Connect drives in winches/cranes exposed to dynamic loads.

Renewable Energy

- Wind Turbines: Couplings between gearboxes and generators, handling variable loads and misalignment.