|

|

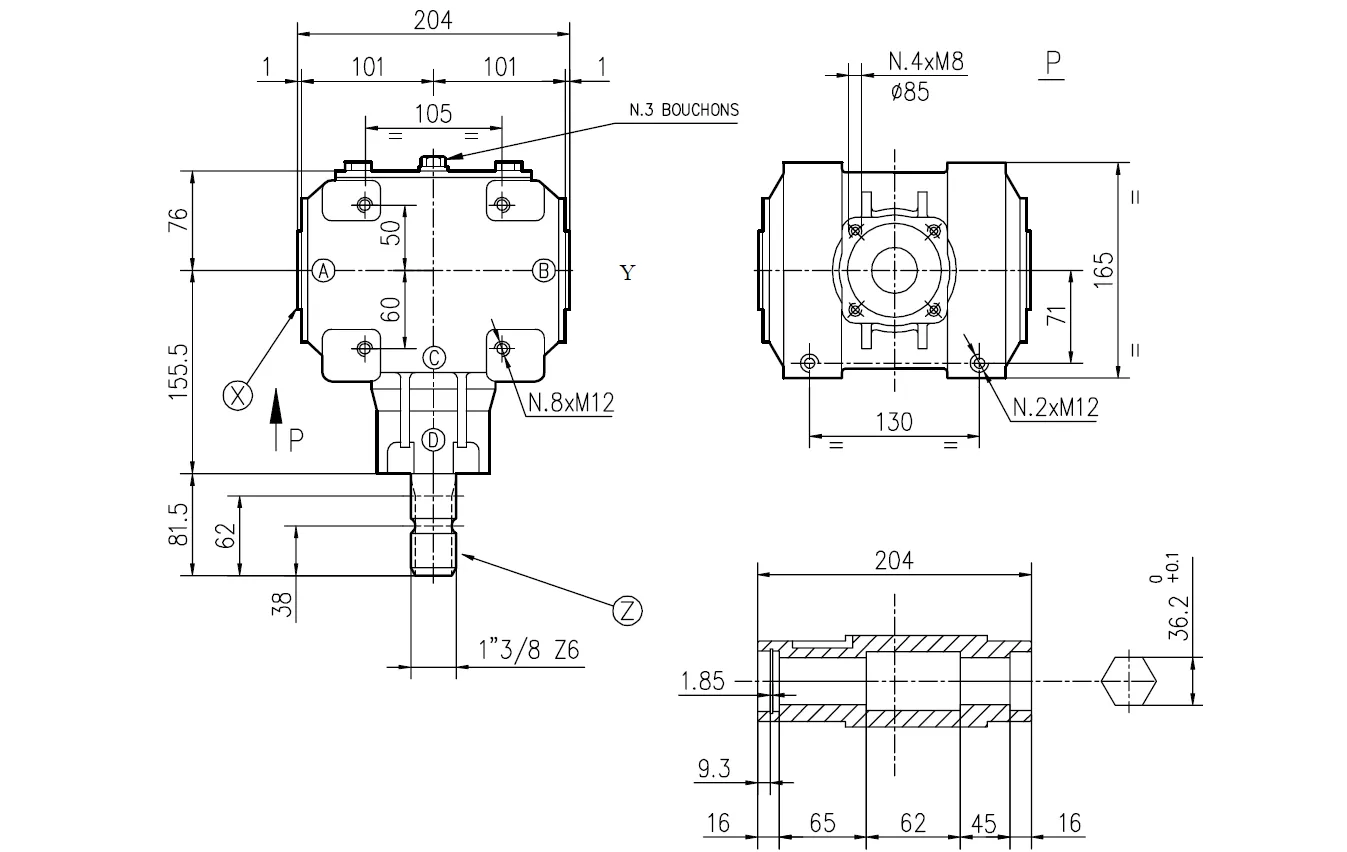

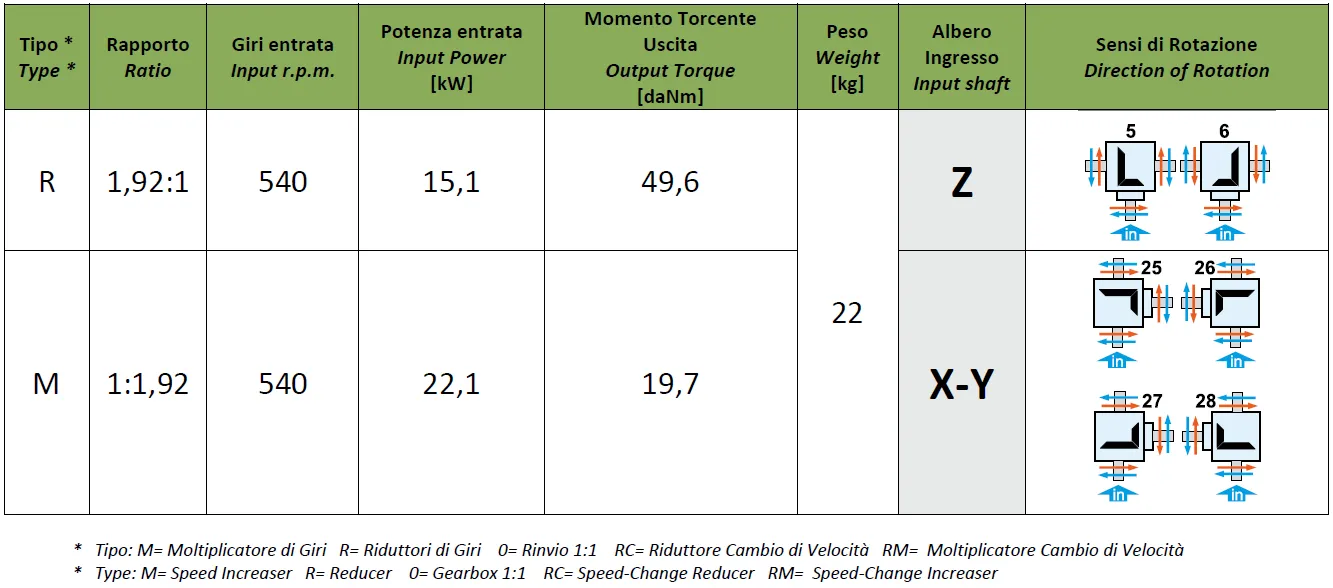

Specifications of Manure Spreader Gearbox TB-27C (1:1.92)

| Description |

Manure Spreader Gearbox – Replacement of Comer Gearbox TB-27C

|

|---|---|

| Application |

|

| Consists of |

|

| Technical information |

|

| Max. input power |

15.1 kW

|

| Max. output torque |

496 nm

|

| Contains oil |

No

|

| Max. oil capacity |

1.1 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| Weight |

22 kg

|

| Gear arrangement |

26

|

| Ratio Increasing |

1: 1.92

|

| Ratio Reducing |

1.92: 1

|

| Shaft X |

1 3/8″ (6) (C)

|

| Shaft Z |

1 3/8″ (6) (A)

|

Benefits of Manure Spreader Gearbox TB-27C (1:1.92)

The Manure Spreader Gearbox TB-27C (1:1.92) offers numerous advantages that make it an excellent choice for agricultural machinery, particularly in manure spreading applications. Here are the key benefits:

1. Enhanced Efficiency

The TB-27C gearbox offers a 1:1.92 ratio, providing optimal speed reduction, which ensures the manure spreader operates at an ideal speed for effective spreading. This ratio enhances overall performance, reducing engine load and improving operational efficiency.

2. Durable and Reliable Performance

Built with high-quality materials and precision engineering, the TB-27C gearbox is designed to withstand heavy-duty use. Its robust construction ensures reliable operation in tough agricultural environments, even under continuous or demanding workloads.

3. Corrosion Resistance

The gearbox is designed to handle the harsh conditions of manure spreading, where exposure to moisture, corrosive materials, and the elements is common. The durable construction and corrosion-resistant materials help extend the life of the gearbox, ensuring long-term performance.

4. Improved Power Transfer

With its carefully engineered gear set, the TB-27C ensures efficient power transmission from the PTO (Power Take-Off) to the spreader’s mechanical components. This leads to smoother operation and less energy loss, contributing to optimal use of the tractor’s power.

5. Longer Service Life

The TB-27C is equipped with high-performance bearings and gears that are designed to endure continuous operation. The precision manufacturing ensures minimal wear and tear, thus extending the service life of the gearbox and reducing the need for frequent repairs or replacements.

Overall, the Manure Spreader Gearbox TB-27C (1:1.92) provides a combination of strength, efficiency, and reliability that enhances productivity, reduces operational costs, and increases the lifespan of agricultural machinery.

Where Are Manure Spreader Gearboxes Used?

Manure spreader gearboxes are essential components in agricultural machinery, specifically designed to drive the mechanical processes of manure spreaders. These gearboxes play a crucial role in transmitting power from the tractor’s PTO (Power Take-Off) to the spreader’s rotating mechanisms, enabling the even distribution of manure across fields. The primary applications of manure spreader gearboxes include:

1. Agricultural Farms

- Field Fertilization: Manure spreader gearboxes are predominantly used on farms for spreading manure as a natural fertilizer. The gearbox helps control the speed and distribution of manure, ensuring efficient fertilization of crops like grains, vegetables, and pasture.

- Organic Farming: In organic farming, manure is a preferred fertilizer. The gearboxes ensure that organic matter is evenly distributed, enriching the soil without the use of synthetic chemicals.

2. Livestock Farms

- Manure Handling: Livestock farms generate significant amounts of manure that need to be managed and distributed. Manure spreader gearboxes assist in spreading animal waste across fields, recycling nutrients back into the soil.

- Waste Management: For farms with cattle, poultry, or hogs, the gearbox-driven spreaders are used to evenly disperse manure, helping to manage waste efficiently and maintain proper sanitation.

3. Dairy Farms

- Manure Application: Dairy farms produce large volumes of manure that need to be spread across fields to improve soil quality and promote healthy grass growth for feed. Manure spreader gearboxes ensure that the manure is spread evenly for optimum fertilization.

- Sustainability: Manure spreaders help dairy farms recycle animal waste into usable fertilizer, reducing the need for synthetic fertilizers and promoting sustainable farming practices.

4. Golf Courses and Sports Fields

- Land Management: Manure spreaders are used on golf courses, sports fields, and parks to enrich the soil, promoting healthy grass and plant growth. Manure spreader gearboxes ensure the efficient, consistent distribution of manure or compost.

- Soil Fertilization: The gearbox-driven spreaders enable precise control over the application of organic materials, helping to maintain lush, green lawns in recreational and athletic spaces.

5. Horticultural Operations

- Soil Enrichment: In large-scale horticultural operations such as nurseries or greenhouses, manure spreader gearboxes are used for soil preparation and fertilization. These gearboxes assist in spreading organic fertilizers to enhance soil health and support plant growth.

- Field Cultivation: Horticultural farms rely on spreaders to distribute nutrients across large areas. The gearboxes provide consistent speed and power transfer to help ensure the even application of manure.

Manure spreader gearboxes are integral to numerous agricultural and land management operations. From large farms and livestock operations to specialized fields like horticulture, forestry, and municipal land management, these gearboxes ensure the efficient, controlled, and sustainable application of manure and organic fertilizers. Their ability to adapt to various machinery and applications makes them a vital component in modern farming and soil management practices.

|

|

Agricultural PTO Shaft for Manure Spreader Gearbox

The Agricultural PTO Shaft is a vital component that connects the tractor’s Power Take-Off (PTO) system to a manure spreader gearbox. Its primary role is to transmit mechanical power from the tractor’s engine to the gearbox, which then drives the spreader’s working mechanisms to distribute manure evenly across fields.

Here’s an in-depth look at the importance, design, and features of PTO shafts for manure spreader gearboxes:

Key Features and Functions

- Power Transmission

- The PTO shaft efficiently transfers power from the tractor’s engine to the manure spreader gearbox, ensuring the spreader operates smoothly.

- It allows the manure spreader to achieve the desired rotation speed, which is critical for evenly spreading manure or other organic fertilizers.

- Durable Construction

- High-Strength Materials: PTO shafts are made from high-quality steel alloys or other durable materials that can withstand high torque and impact loads.

- Corrosion Resistance: Designed for use in challenging agricultural environments, PTO shafts are typically coated or treated to resist corrosion from manure, moisture, and soil.

- Heavy-Duty Design: Given the often demanding nature of manure spreading, these shafts are built to endure prolonged use without compromising on strength or reliability.

- Flexibility & Adaptability

- Adjustable Length: Many PTO shafts come with telescoping sections that can be adjusted for the desired length, offering compatibility with a wide range of manure spreader models.

- Universal Joints: PTO shafts are fitted with universal joints that allow for angular flexibility, ensuring smooth power transfer even when the tractor and the manure spreader are not aligned perfectly in a straight line.

- Quick-Connect Mechanism: A PTO shaft with a quick-connect coupling ensures that the operator can easily connect and disconnect the shaft from the manure spreader gearbox, reducing downtime and improving operational efficiency.

- Safety Features

- Protective Shields: PTO shafts are often equipped with safety shields to prevent accidental contact with rotating parts, ensuring the operator’s safety.

- Overload Protection: Some PTO shafts are equipped with safety clutches that disengage in case of an overload, protecting the tractor’s PTO system and the manure spreader gearbox from damage.

Benefits of Agricultural PTO Shaft for Manure Spreader Gearboxes

- Efficient Power Transfer

- The PTO shaft ensures that power is transferred efficiently from the tractor to the manure spreader gearbox, resulting in consistent and optimal performance during manure application.

- Durability and Longevity

- Designed to handle the rigors of agricultural operations, PTO shafts are built to last, reducing maintenance and replacement costs over time. Their ability to withstand heavy loads, impacts, and corrosive environments enhances the longevity of both the PTO shaft and the manure spreader gearbox.

- Cost-Effective Solution

- By ensuring that the manure spreader operates efficiently, the PTO shaft helps farmers save on fuel and labor costs. The power transfer efficiency also helps reduce wear and tear on machinery, leading to fewer repairs and longer service life for both the tractor and manure spreader.

- Improved Application Precision

- A properly functioning PTO shaft enables the manure spreader to distribute manure evenly across fields, ensuring precise fertilization for crops. This helps optimize crop growth while reducing waste and ensuring sustainable soil fertility management.

- Enhanced Operational Flexibility

- With adjustable lengths and universal joints, the PTO shaft offers great flexibility, allowing it to be used with various models of manure spreaders and tractors, making it a versatile choice for many agricultural operations.

The Agricultural PTO Shaft for Manure Spreader Gearbox is a vital component that ensures efficient power transmission from the tractor to the manure spreader. With its durable construction, adaptability, and safety features, it plays a crucial role in ensuring that manure spreaders work effectively, providing benefits such as efficient manure application, enhanced field fertilization, and long-term durability. By selecting a high-quality PTO shaft, agricultural operations can optimize their manure spreading processes, resulting in more productive, sustainable, and cost-effective farming.

About FMP

Headquartered in Italy, FMP stands as a distinguished leader in the design, development, and production of high-performance gearboxes, with a specialized focus on the agricultural machinery sector. Known for our precise engineering, innovative solutions, and unwavering reliability, FMP has earned a strong reputation as a trusted partner in both agricultural and industrial markets. Our extensive portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a broad range of other essential components, each meticulously designed to meet the unique demands of diverse applications.

At FMP, we recognize that every client faces distinct challenges. This understanding drives our commitment to delivering tailored solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution not only meets their specific needs but also optimizes performance and maximizes overall value. Our emphasis on timely, professional responses and expert guidance guarantees that every inquiry is addressed with precision, consistently yielding the best results.

We prioritize transparent and ongoing communication throughout the entire product development lifecycle. Our dedicated team collaborates closely with clients to fully understand their requirements and offer valuable insights and recommendations that lead to the best possible outcomes. Whether we’re designing cutting-edge products or fulfilling routine orders, FMP remains committed to delivering high-quality, precision-engineered solutions, on time, every time. Our goal is to surpass client expectations, delivering exceptional service and results in every project.

At the core of FMP’s operations is an unwavering commitment to quality. We adhere to the highest manufacturing standards and implement rigorous quality control processes, ensuring each product exceeds industry benchmarks. This commitment to excellence, coupled with our core values of integrity, teamwork, and perseverance, has allowed us to foster long-lasting, trust-based relationships with clients across nearly 30 countries globally.

FMP is dedicated to cultivating global partnerships by offering expert advice and customized solutions that evolve with our clients’ needs. We aim to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you’re seeking innovative solutions for a new initiative or require ongoing support for an existing system, FMP is here to help you overcome technical challenges and ensure your continued success.

Author: CX