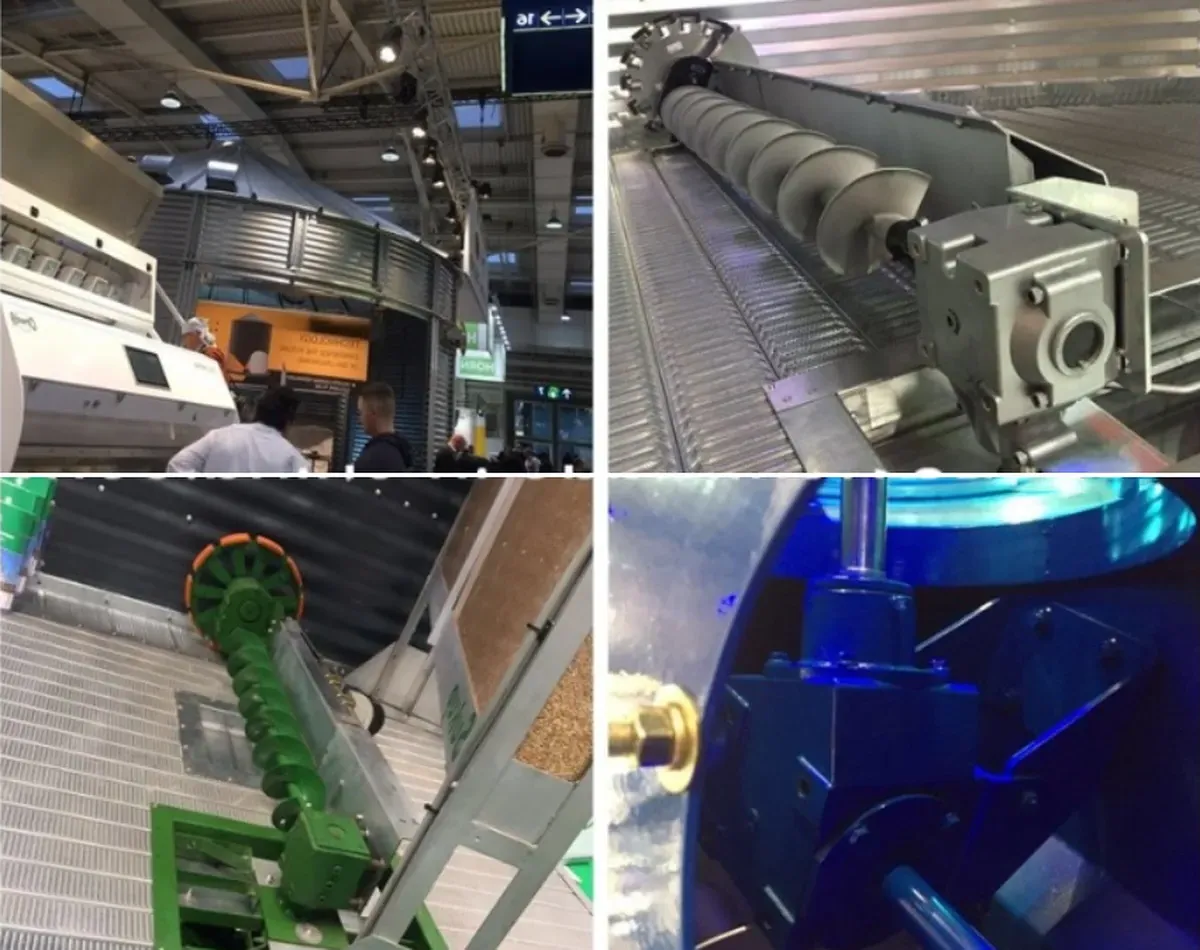

Grain Storage Gearbox FMP-1005 Specifications

| Product Name | Grain storage gearbox |

| Material | HT250 for housing, 40CrMnTi for gear shaft. |

| Color | Customization |

| Mould No | 6.5 |

| Used | Grain storage |

Benefits of Using Grain Storage Gearbox FMP-1005

The Grain Storage Gearbox FMP-1005 offers several benefits that enhance its functionality, efficiency, and reliability in agricultural grain storage systems. Below are the key advantages of using this gearbox:

1. Enhanced Efficiency

- Power Transmission Optimization: The FMP-1005 gearbox is designed to efficiently transmit power from the motor to the grain handling machinery. It reduces energy loss, ensuring that a significant portion of the input power is effectively converted into output power. This leads to more efficient operation, reducing energy consumption and lowering operational costs.

2. High Torque Capacity

- Improved Load Handling: The FMP-1005 gearbox is built to handle high torque, making it suitable for demanding grain storage applications that require substantial force to move or process grain. It can power heavy-duty equipment such as conveyors, augers, and grain elevators, ensuring smooth operation under heavy loads.

3. Smooth and Reliable Operation

- Reduced Vibration and Noise: With precision engineering, the FMP-1005 gearbox provides a smooth operation with minimal vibrations. This not only ensures more stable and consistent performance but also reduces noise levels in the grain storage area, creating a more comfortable working environment.

4. Durability and Longevity

- Robust Design: The gearbox is constructed using high-quality materials that can withstand the tough environmental conditions of agricultural settings, such as dust, moisture, and temperature variations. Its robust design ensures long-lasting performance, reducing the need for frequent maintenance or replacements.

5. Minimal Maintenance

- Long-Lasting Components: With its high-strength gears and well-designed lubrication system, the FMP-1005 gearbox requires less frequent maintenance. The internal components are protected against wear and tear, reducing downtime and service costs over time.

The Grain Storage Gearbox FMP-1005 provides several significant benefits, including enhanced operational efficiency, high torque capacity, reliability, and durability. Its smooth operation, minimal maintenance requirements, and versatility in various applications make it an essential component for optimizing grain storage and handling systems. This gearbox not only ensures better performance but also helps reduce operating costs and extend the lifespan of agricultural machinery.

Benefits of Using Grain Storage Gearbox FMP-1005

The Grain Storage Gearbox FMP-1005 is commonly used in a variety of agricultural and industrial applications related to grain handling and storage. Below are some of the primary applications of this gearbox:

1. Grain Conveyors

- Function: The FMP-1005 gearbox powers grain conveyors, which transport grain from one location to another within a storage facility. It ensures smooth and efficient movement of grain over long distances, reducing delays and improving throughput.

- Benefits: Helps in handling large volumes of grain, providing consistent speed and torque for continuous operation.

2. Grain Elevators

- Function: The gearbox is used in grain elevators to lift grain vertically from lower levels to higher storage silos or bins. Its high torque capacity enables the elevator system to handle heavy loads.

- Benefits: Ensures reliable operation under heavy lifting conditions, minimizing the risk of downtime and damage to the machinery.

3. Augers for Grain Handling

- Function: FMP-1005 gearboxes are commonly used in augers, which are employed to move grain into storage bins, silos, or trailers. Augers are vital for transferring grains from one container to another.

- Benefits: Provides smooth, consistent movement and power to the auger system, ensuring efficient grain transfer with minimal grain damage.

4. Grain Sorting and Cleaning Machines

- Function: The gearbox is used in machines that sort and clean harvested grain. These machines separate debris from the grain and sort it by size or quality.

- Benefits: Supports consistent, reliable power transmission, which is essential for continuous and smooth operation of sorting and cleaning processes.

5. Grain Dryers

- Function: The gearbox can be found in grain drying equipment, where it drives components like fans, conveyors, and augers that circulate hot air through the grain to reduce moisture content.

- Benefits: Enhances the drying efficiency by ensuring smooth operation of the drying system, which is critical for preserving grain quality.

The Grain Storage Gearbox FMP-1005 is a versatile component used in various grain handling and storage applications. Its robust design and reliable performance make it ideal for powering conveyors, augers, elevators, cleaning systems, and other critical machinery used in grain processing, storage, and transportation. Its adaptability ensures smooth operation, reduces downtime, and maximizes the efficiency of grain handling systems in both large-scale and smaller-scale agricultural settings.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in designing, developing, and producing high-performance gearboxes, with a primary focus on the agricultural machinery sector. Known for its precision engineering, innovative solutions, and steadfast reliability, FMP has earned a reputation as a trusted partner within both agricultural and industrial markets. Our comprehensive portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide range of essential components, all meticulously crafted to meet the specific demands of various applications.

At FMP, we understand that every client faces unique challenges. This is why we specialize in delivering tailored solutions, whether for individual components or fully integrated systems. Through close collaboration with our clients, we ensure that each solution not only meets their needs but also optimizes performance and maximizes value. Our commitment to swift, professional responses and expert guidance guarantees that every inquiry is addressed with precision, ensuring the best outcomes every time.

We prioritize clear, continuous communication throughout the entire product development cycle. Our dedicated team works closely with clients to thoroughly understand their requirements and provide valuable insights and recommendations to achieve optimal results. Whether designing state-of-the-art products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our mission is to consistently exceed client expectations, providing exceptional service and results with every project.

Quality is at the heart of FMP’s operations. We uphold the highest manufacturing standards and implement rigorous quality control measures to ensure that each product meets, and often exceeds, industry benchmarks. This commitment to excellence, along with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is always eager to cultivate global partnerships, offering expert advice and customized solutions that address the evolving needs of our clients. We strive to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you require innovative solutions for a new initiative or ongoing support for an existing system, FMP is ready to help you overcome technical challenges and ensure your continued success.

Author: CX