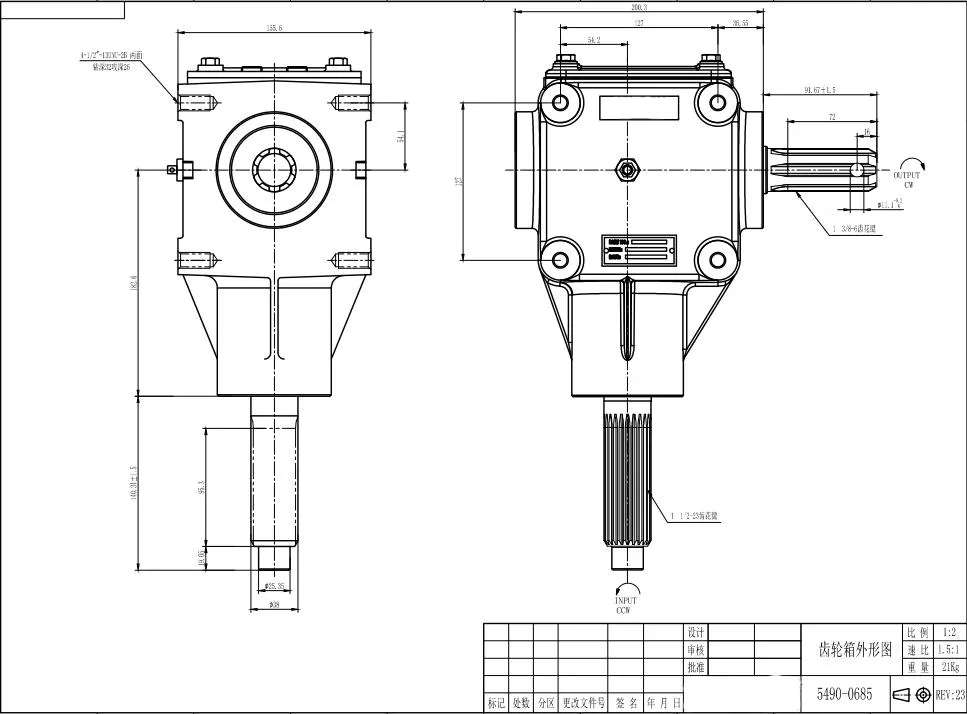

Grain Storage Gearbox FMP-5490 Specifications

| Product Name | Grain storage gearbox |

| Material | HT250 for housing, 20CrMnTi for gear shaft. |

| Color | Customization |

| Weight | 21KG |

| Ratio | 1.5:1 |

| Power | 40HP |

| Used | Grain storage |

Benefits of Using the L Series Grain Storage Gearbox for Agricultural

The L Series Grain Storage Gearbox offers several key benefits for agricultural applications, particularly in grain storage systems. These benefits include:

1. Durability and Longevity

- The L Series gearboxes are designed to withstand the demanding conditions of agricultural environments. Built with high-quality materials, they are resistant to wear and tear, offering long-lasting performance in grain storage systems that operate under heavy loads and continuous use.

2. High Efficiency

- With precision engineering, the L Series gearboxes provide exceptional efficiency in transferring power. This results in smooth, reliable operation of equipment such as grain conveyors, augers, and elevators, helping to optimize performance and reduce energy consumption.

3. Compact and Space-Saving Design

- The compact design of the L Series gearboxes allows for easy integration into tight spaces within grain storage systems. Their small footprint ensures that they do not take up unnecessary space while still delivering the power required for efficient grain handling.

4. Reliable Performance in Harsh Conditions

- Agricultural environments can be harsh, with exposure to dust, moisture, and varying temperatures. The L Series gearboxes are designed to operate reliably even in these tough conditions, ensuring uninterrupted operation of grain storage equipment and minimizing downtime.

5. Customization Options

- The L Series gearboxes can be tailored to meet the specific needs of different grain storage systems. Whether for varying capacities, unique operational requirements, or different mounting configurations, FMP offers flexible solutions to ensure compatibility with a range of agricultural machinery.

In summary, the L Series Grain Storage Gearbox delivers durability, efficiency, and reliability, making it an ideal choice for agricultural applications where grain storage and handling equipment must perform under demanding conditions.

Applications of the L Series Grain Storage Gearbox for Agricultural

The L Series Grain Storage Gearbox is versatile and can be used in a variety of agricultural applications, particularly in systems related to grain handling and storage. Some of the primary applications include:

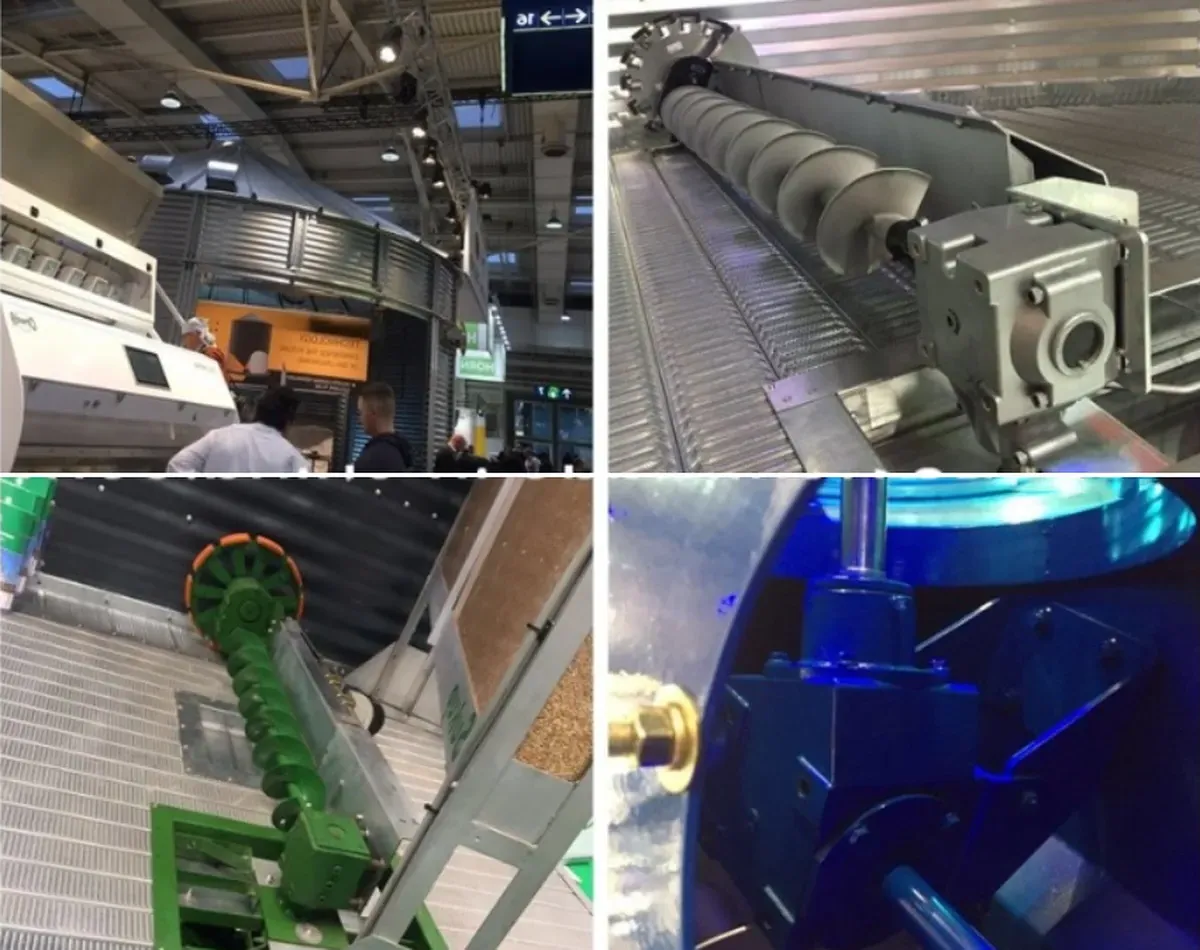

1. Grain Elevators

- The L Series gearbox is widely used in grain elevators, where it drives the vertical transportation of grain from one level to another. Its reliability and durability ensure smooth operation, even under heavy loads, making it ideal for elevating grain to storage bins or silos.

2. Grain Conveyors

- In grain conveyor systems, the L Series gearbox plays a key role in transferring grain horizontally or at an incline. It ensures efficient and continuous movement of bulk grain from one location to another, whether for loading, unloading, or storage.

3. Grain Augers

- The L Series gearbox is commonly used in grain augers, which are vital for moving grain from one place to another, often from bins to trucks or storage areas. The gearbox provides the necessary torque and reliability for efficient operation.

4. Grain Handling Equipment

- The L Series gearbox is an essential component in various other grain handling machines, including those used for mixing, sorting, and drying. Its rugged construction makes it ideal for continuous, heavy-duty operations.

5. Grain Bin Sweeps

- The L Series gearbox is used in grain bin sweep augers, which help remove grain from storage bins. It drives the sweeper mechanism that ensures efficient emptying of grain from bins, reducing the need for manual labor.

In essence, the L Series Grain Storage Gearbox is designed to meet the diverse demands of grain storage, handling, and transportation, ensuring reliable, efficient, and cost-effective solutions in agricultural operations. Its robust performance in a range of applications helps optimize workflow and improve productivity across the agricultural sector.

Working Principle of the L Series Grain Storage Gearbox for Agricultural

The L Series Grain Storage Gearbox is designed to efficiently transfer power and provide the necessary torque for various agricultural applications, particularly in grain storage systems. Below is a breakdown of the working principle of the L Series gearbox:

1. Power Input

The gearbox receives power from a prime mover, typically an electric motor, engine, or PTO (Power Take-Off) system. This power is transmitted via an input shaft connected to the driving motor.

2. Transmission of Motion

The L Series gearbox is designed with multiple gears that facilitate the transfer of rotational energy from the input shaft to the output shaft. As the input shaft rotates, it engages with the gears inside the gearbox, which convert the rotational motion into the desired torque and speed for the application.

3. Gear Reduction

The L Series gearbox uses a series of gear reductions to step down the speed of the input shaft while simultaneously increasing the output torque. This reduction in speed allows for more controlled and efficient operation of the equipment it’s driving, such as conveyors, augers, and other grain handling machinery.

4. Torque Transmission

The gearbox provides torque to the output shaft, which is directly connected to the agricultural machinery, such as grain elevators or augers. The L Series gearbox ensures that the necessary torque is delivered without overloading the motor or other components of the system.

5. Efficient Power Conversion

The L Series gearbox is designed with high-efficiency gears that minimize energy loss during the transmission process. This ensures that a significant portion of the input power is converted into usable output power, thereby optimizing fuel consumption or electricity usage in the system.

In summary, the L Series Grain Storage Gearbox efficiently converts power from the motor or PTO, steps down the speed while increasing torque, and provides smooth and reliable motion to the connected agricultural equipment. This enables optimal performance in grain handling and storage, making it an essential component in many agricultural applications.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a primary emphasis on the agricultural machinery sector. Celebrated for precision engineering, innovative solutions, and unwavering reliability, FMP has built a solid reputation as a trusted partner within both the agricultural and industrial markets. Our expansive portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide variety of essential components—each meticulously designed to meet the specific demands of diverse applications.

At FMP, we understand that each client faces distinct challenges. This understanding drives our specialization in delivering tailored solutions, whether for individual components or fully integrated systems. By collaborating closely with our clients, we ensure that every solution not only meets their unique needs but also enhances performance and maximizes value. Our commitment to timely, professional responses and expert guidance guarantees that every inquiry is addressed with precision, consistently delivering optimal results.

We place a strong emphasis on clear, continuous communication throughout the entire product development cycle. Our dedicated team works hand-in-hand with clients to deeply understand their requirements and provide valuable insights and recommendations that ensure the best outcomes. Whether we are designing cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on schedule, every time. Our mission is to consistently exceed client expectations, delivering exceptional service and results with every project.

Quality lies at the core of FMP’s operations. We adhere to the highest manufacturing standards and implement rigorous quality control processes to ensure that each product not only meets but exceeds industry benchmarks. This unwavering dedication to excellence, combined with our core values of integrity, teamwork, and perseverance, has allowed us to forge long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

At FMP, we are always eager to cultivate global partnerships by offering expert advice and customized solutions that address the ever-evolving needs of our clients. We aim to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you require innovative solutions for a new initiative or ongoing support for an existing system, FMP is ready to assist you in overcoming technical challenges and ensuring your continued success.

Author: CX