Jaw couplings represent a versatile mechanical component widely used for power transmission applications. This flexible coupling mechanism functions by interconnecting two rotating shafts to transmit rotational force while simultaneously absorbing vibrational energy and compensating for axial/angular misalignments. Such operational characteristics help safeguard connected machinery from excessive stress and premature wear.

The assembly comprises three primary components:

- Dual metallic hubs featuring radial protrusions (jaw elements)

- A resilient elastomeric insert (commonly called a spider element)

These components are precision-assembled in an alternating engagement pattern where the hub jaws interlock with the spider’s compliant lobes. Torque transmission occurs through elastic deformation of the compressed polymer insert, which provides both torsional flexibility and damping properties. The spider’s viscoelastic material characteristics enable effective vibration attenuation while maintaining continuous power transfer between connected shafts.

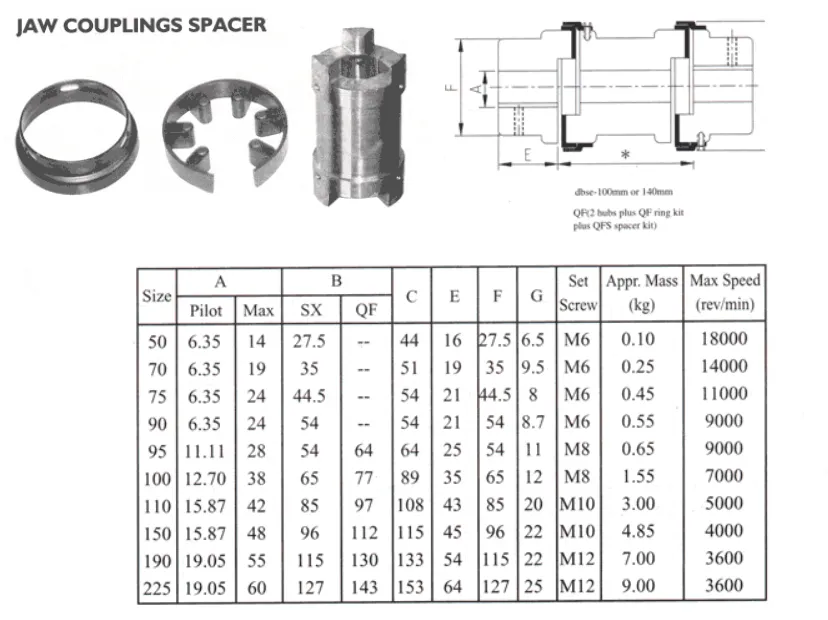

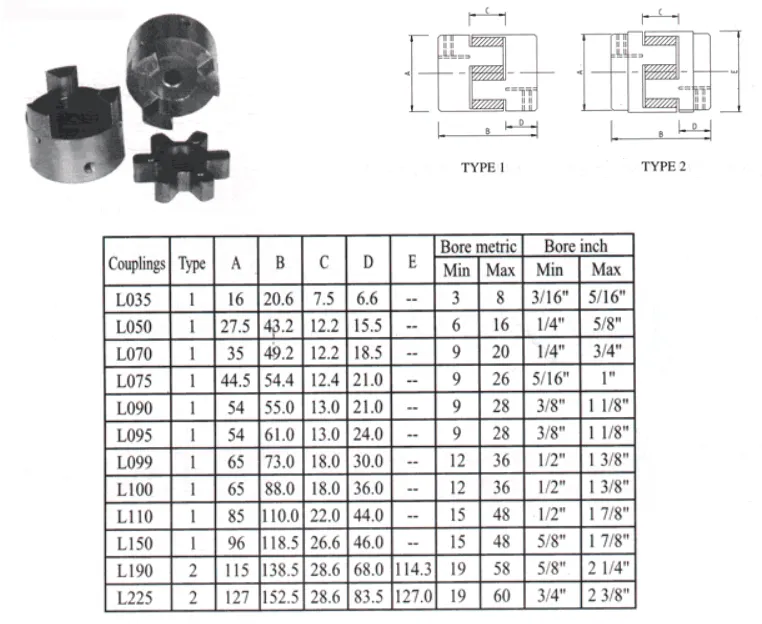

Jaw Coupling Dimensions

Features of Jaw-Type Flexible Couplings

The elastomeric components in jaw-type couplings are typically engineered from high-performance plastics or rubber. These inserts define the coupling’s operational lifespan, which generally spans up to 10 years under standard conditions. Due to their design, elastomers primarily endure compressive forces rather than tensile stress. Known for their vibration damping and shock absorption properties, these couplings are ideal for high-vibration environments. Unlike rigid couplings, their operational temperature range (-35°C to +80°C) is dictated by the elastomer’s thermal limits.

Key Advantages:

- Compact Design: Backlash-free construction with elastomer options in three hardness grades.

- Dynamic Performance: Effectively dampens vibrations and accommodates radial/angular misalignment.

- Ease of Use: Simplified structure for straightforward installation, inspection, and maintenance.

- Durability: Maintenance-free operation with oil resistance and electrical insulation; optimal performance between 20°C and 60°C.

- Elastomer Variants: Features multi-lobe configurations (4, 6, 8, or 10 petals) for tailored flexibility.

- Mounting Options: Supports diverse installation methods, including set screws, clamping mechanisms, and keyway fixation.