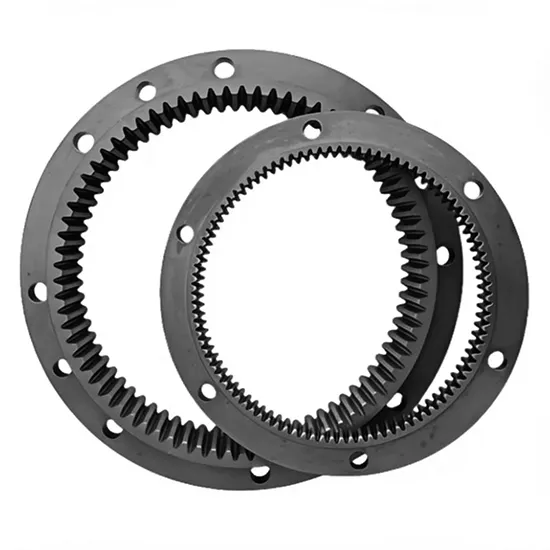

Understanding Internal Ring Gears

Internal ring gears are essential components in mechanical systems designed to reduce speed and increase torque in inline shaft applications. Unlike external gears, these cylindrical gears feature teeth cut into the inside diameter, allowing them to mesh seamlessly with spur gears or pinions. This design enables the driving pinion to rotate within the gear, delivering smooth and efficient performance. Internal ring gears are widely utilized in planetary gear systems, gear couplings, and other setups requiring compact, high-torque solutions. Manufacturing these gears typically involves gear shaping machines with pinion cutters, though modern techniques like skiving have enhanced production efficiency. However, their complex geometry poses challenges—especially for thinner rings, which may face structural integrity issues or stresses from machining.

Specification

Internal ring gear having toothed on the inner surface of its rim.

| Products | Internal Ring Gear |

| Custom Made | √ |

| Gear Profile Type | Cylindrical Ring Gear |

| Gear Teeth manufacturing | Gear Shaping |

| Gear Teeth Grinding | * If needed |

| Module (M) | Custom |

| Number of Teeth (Z) | Custom |

| Pressure Angle (α) | Custom |

| Helix Angle (β) | Custom |

| Teeth Accuracy Grade | ISO 8-9 Grade |

| Heat Treatment | Quenching & Tempring/ Induction Hardening |

| Hardness | 230-260 HB |

| STEEL CODE GRADES COMPARISON | |||||

| CHINA/GB | ISO | ГΟСТ | ASTM | JIS | DIN |

| 45 | C45E4 | 45 | 1045 | S45C | CK45 |

| 40Cr | 41Cr4 | 40X | 5140 | SCr440 | 41Cr4 |

| 20CrMo | 18CrMo4 | 20ХМ | 4118 | SCM22 | 25CrMo4 |

| 42CrMo | 42CrMo4 | 38XM | 4140 | SCM440 | 42CrMo4 |

| 20CrMnTi | 18XГT | SMK22 | |||

| 20Cr2Ni4 | 20X2H4A | ||||

| 20CrNiMo | 20CrNiMo2 | 20XHM | 8720 | SNCM220 | 21NiCrMo2 |

| 40CrNiMoA | 40XH2MA/ 40XHMA |

4340 | SNCM439 | 40NiCrMo6/ 36NiCrMo4 |

|

| 20CrNi2Mo | 20NiCrMo7 | 20XH2MA | 4320 | SNCM420 | |

Design and Application Insights

The performance of an internal ring gear hinges on key parameters like outer diameter, thickness, and tooth profile. A sufficiently large outer diameter ensures structural stability, while adequate thickness prevents excessive stress during operation. These gears can be crafted from materials such as steel, brass, bronze, or plastic, with hardening applied based on strength and durability needs. When pairing with a spur gear or pinion, compatibility in pitch, pressure angle, and helix angle (for helical gears) is critical, alongside checks for involute, trochoid, and trimming interferences to ensure flawless functionality. Internal gears shine in planetary gear drives, offering diverse speed transmission ratios and rotational directions depending on the configuration, making them a versatile choice across industries.

FMP: Your Trusted Partner in Italy

At FMP, we pride ourselves on producing a wide array of internal ring gears to meet industrial demands throughout Italy, from Milan’s thriving manufacturing hubs to Venice’s precision engineering centers, Florence’s artisanal workshops, and Bologna’s automotive sector. Our product range includes standard internal gears in various sizes and specifications, but our strength lies in customization—tailoring solutions to your exact needs. If you don’t see your desired model in our product list, it simply means we haven’t listed it yet. Reach out via email with your specifications, and our skilled engineers will reply within 24 hours with a tailored solution.