Hydraulic Cylinder for Ro-ro Platform

The Hydraulic Cylinder for Ro-Ro Platform is an essential hydraulic component designed to enhance the functionality and efficiency of roll-on/roll-off (Ro-Ro) vessels. This cylinder plays a critical role in the operation of the platform’s ramps, enabling smooth lifting and lowering to facilitate the seamless loading and unloading of vehicles and cargo.

Key Features:

- High Load Capacity: Engineered to handle significant weights, this hydraulic cylinder ensures safe and reliable operation under heavy loads typical of Ro-Ro operations.

- Robust Construction: Made from high-strength materials, it is built to withstand the harsh marine environment, including exposure to seawater and extreme conditions, ensuring long-lasting durability and reliability.

- Smooth Operation: The advanced hydraulic design allows for precise control and smooth movements, enabling quick adjustments during loading and unloading processes.

- Enhanced Safety: Equipped with safety features to prevent accidental activation and ensure secure operations, protecting both personnel and cargo.

- Versatile Application: Suitable for various Ro-Ro platforms, this hydraulic cylinder can adapt to different operational needs, making it an ideal choice for diverse maritime logistics tasks.

- Low Maintenance Requirements: Designed for minimal wear and tear, it reduces maintenance needs and operational downtime, contributing to overall productivity.

In summary, the Hydraulic Cylinder for Ro-Ro Platform is a vital component for optimizing the performance and safety of Ro-Ro vessels, significantly improving the efficiency of maritime transportation and cargo handling operations.

Ro-ro Platform Main Operating Cylinder

The Ro-Ro Platform Main Operating Cylinder is a vital hydraulic component designed to manage the primary lifting and lowering functions of roll-on/roll-off (Ro-Ro) vessels. This cylinder provides the necessary force to operate the platform’s ramps and other mechanisms, ensuring smooth and efficient loading and unloading of vehicles and cargo. Constructed from high-strength materials, it is built to withstand the harsh marine environment and the significant stresses associated with heavy loads, ensuring long-lasting durability and reliable performance. The advanced hydraulic design allows for precise control and rapid adjustments, enhancing operational efficiency and safety during cargo operations. This main operating cylinder is essential for optimizing the functionality of Ro-Ro platforms, significantly contributing to effective maritime logistics and transportation.

| Product Name | Ro-ro Platform Main Operating Cylinder |

| Features: | Retract the springboard and ramp |

| Bore diameter: | 100mm~400mm |

| Rod diameter: | 50mm~180mm Stroke≤7300mm |

| Thrust force: | Maximum 3500KN (Cylinder diameter: 125mm/pressure28MPa) |

| Applications: | Ro-ro Platform |

Ro-ro Platform Latch Cylinder (Mechanical Self-Locking)

The Ro-Ro Platform Latch Cylinder (Mechanical Self-Locking) is a specialized hydraulic component designed for roll-on/roll-off (Ro-Ro) applications, ensuring secure and reliable locking of platform mechanisms during loading and unloading operations. This self-locking cylinder features a robust mechanical design that automatically engages when the platform is in position, preventing accidental disengagement and enhancing safety. Its durable construction is engineered to withstand harsh marine environments, making it ideal for use in various transport and logistics scenarios. With precise control and ease of operation, the Ro-Ro Platform Latch Cylinder ensures efficient and safe handling of cargo, contributing to streamlined logistics processes.

| Product Name | Ro-ro Platform Latch Cylinder |

| Features: | Lock the bolt after the springboard or ramp is recovered in place |

| Specification: | Specifications: 80/45*S, 60/32*S,front and rear locking Having DNVGL-type approval With standard size series selection |

| Pressure | 25MPa (stainless steel piston rod) |

| Applications: | Ro-ro Platform |

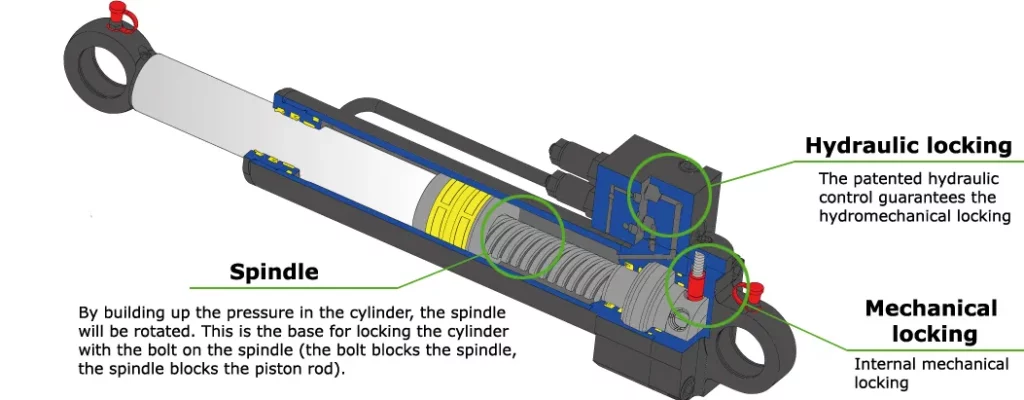

Ro-Ro Platform Latch Cylinder (Hydraulic Self-Locking)

The Ro-Ro Platform Latch Cylinder is an essential hydraulic component that secures and releases the ramps on roll-on/roll-off (Ro-Ro) vessels. This cylinder provides the necessary force to engage the latching mechanism, ensuring that the ramps are safely locked during transit and easily released for loading and unloading operations. Made from high-strength materials, it is designed to withstand the harsh marine environment and the heavy stresses associated with cargo handling. The smooth hydraulic action allows for quick and precise operation, enhancing safety and efficiency during cargo transfers. This latch cylinder is vital for the reliable performance of Ro-Ro platforms, significantly improving maritime logistics and operational effectiveness.

| Product Name | Ro-ro Platform Latch Cylinder |

| Features: | Lock the bolt after the springboard or ramp is recovered in place |

| Specification: | Specifications: 80/50*S, 63/40*S, 40/28*S,front and rear Having DNVGL type approval With standard size series selection |

| Pressure | 25MPa (stainless steel piston rod) |

| Applications: | Ro-ro Platform |

Ro-Ro Platform Jacking Cylinder

| Product Name | Ro-Ro Platform Jacking Cylinder |

| Features: | Retract the springboard and ramp |

| Bore diameter: | 50mm~125mm |

| Rod diameter: | 25mm~75mm Stroke≤1000mm |

| Thrust force: | Maximum 361KN (Bore diameter: 125mm/pressure29.4MPa) |

| Applications: | Ro-ro Platform |

Advantages of Ro-Ro Platform Hydraulic Cylinder

The Ro-Ro Platform Hydraulic Cylinder offers numerous advantages that enhance the performance and reliability of roll-on/roll-off (Ro-Ro) vessels.

One of the primary benefits is its high load capacity, which allows for the safe and efficient handling of heavy vehicles and cargo during loading and unloading operations. This ensures that the platform can accommodate a variety of loads without compromising safety.

The hydraulic cylinder also provides precise control, enabling smooth and accurate movements of the ramps. This precision is crucial for preventing accidents and ensuring that vehicles can safely navigate on and off the platform.

Constructed from robust materials, the cylinder is designed to withstand the harsh marine environment, including exposure to saltwater and extreme weather conditions. This durability ensures long-lasting performance, reducing the need for frequent replacements or repairs.

Another significant advantage is the enhanced safety features integrated into the hydraulic design. These features help prevent accidental activation and overextension, protecting both personnel and cargo during operations.

The hydraulic cylinder’s versatility allows it to be used with various Ro-Ro platforms, making it adaptable to different operational needs and enhancing its utility in maritime logistics.

Additionally, it requires low maintenance, which helps minimize downtime and operational costs. The design focuses on reducing wear and tear, ensuring that the cylinder remains functional for extended periods.

Finally, the smooth hydraulic operation provided by the cylinder contributes to overall operational efficiency. Quick adjustments facilitate faster loading and unloading processes, improving turnaround times and productivity in maritime transportation.

Overall, the Ro-Ro Platform Hydraulic Cylinder is essential for optimizing the efficiency, safety, and reliability of Ro-Ro vessels in the logistics and shipping industry.

Application of Ro-Ro Platform Hydraulic Cylinder

The Ro-Ro Platform Hydraulic Cylinder is utilized in various applications within the maritime and logistics sectors, playing a vital role in enhancing the efficiency and safety of roll-on/roll-off (Ro-Ro) vessels. Here are some key applications:

In vehicle transportation, the hydraulic cylinder is essential for lifting and lowering the ramps of Ro-Ro vessels, allowing for the seamless loading and unloading of cars, trucks, and other vehicles. This application is crucial for ferry services and shipping lines that transport vehicles across waters.

During cargo handling, the hydraulic cylinder facilitates the movement of various types of cargo, including heavy machinery and equipment, ensuring safe and efficient transfers. Its precise control enables operators to manage the loading process effectively, reducing the risk of accidents.

In maritime logistics, the hydraulic cylinder is used to optimize the operations of Ro-Ro terminals and docks. By enabling quick adjustments to the ramps, it enhances the overall efficiency of loading and unloading operations, helping to minimize turnaround times for vessels.

The hydraulic cylinder is also crucial in ferry services, where it allows for the rapid and safe embarkation and disembarkation of passengers and vehicles. This application is vital for maintaining schedules and ensuring customer satisfaction in passenger transport.

In construction and infrastructure projects, Ro-Ro vessels equipped with hydraulic cylinders are used to transport heavy materials and equipment to offshore sites. The ability to quickly load and unload large items makes these vessels an ideal choice for such applications.

Furthermore, the hydraulic cylinder plays a role in emergency response operations, where Ro-Ro vessels may be used to transport rescue equipment and personnel to affected areas. The efficient loading and unloading capabilities of these vessels can be critical in disaster relief scenarios.

Overall, the Ro-Ro Platform Hydraulic Cylinder is integral to various applications, significantly contributing to the efficiency, safety, and reliability of maritime operations across different sectors.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX