What Are Herringbone Gears?

A herringbone gear is a specific type of double helical gear characterized by its distinctive V-shaped tooth pattern. Imagine two helical gears with opposite hands—left and right—joined side by side. From above, the grooves resemble the letter “V,” forming a herringbone pattern, much like the bones of a fish. Unlike standard helical gears, herringbone gears eliminate additional axial loads because the thrust from one side cancels out the thrust from the other. This unique design makes them ideal for high-torque applications where stability and efficiency are paramount.

Advantages of Herringbone Gears

Herringbone gears stand out due to several key benefits:

- No Axial Load: The opposing helical teeth neutralize axial thrust, eliminating the need for substantial thrust bearings and simplifying mechanical designs.

- Smooth Power Transmission: Multiple teeth engage simultaneously, ensuring smooth, quiet operation with minimal vibration—perfect for precision machinery.

- High Load Capacity: The extended tooth length allows herringbone gears to handle significant torque, making them a top choice for heavy-duty equipment.

- Enhanced Durability: The balanced design reduces wear, extending the gear’s lifespan even under demanding conditions.

These advantages make herringbone gears a superior alternative to traditional helical or spur gears in specific applications.

Herringbone Gear Material

42CrMo steel and 40CrNiMo steel are generally used for the production of herringbone gears.

| Custom Made | √ |

| Gear Profile Type | Herringbone |

| Gear Teeth manufacturing | Gear Milling |

| Gear Teeth Grinding | Null |

| Module (M) | 10 |

| Number of Teeth (Z) | 30 |

| Pressure Angle (α) | 20° |

| Helix Angle (β) | Custom |

| Teeth Accuracy Grade | ISO 8-9 |

| Heat Treatment | Quenching & Tempering |

| STEEL CODE GRADES COMPARISON | |||||

| CHINA/GB | ISO | ГΟСТ | ASTM | JIS | DIN |

| 45 | C45E4 | 45 | 1045 | S45C | CK45 |

| 40Cr | 41Cr4 | 40X | 5140 | SCr440 | 41Cr4 |

| 20CrMo | 18CrMo4 | 20ХМ | 4118 | SCM22 | 25CrMo4 |

| 42CrMo | 42CrMo4 | 38XM | 4140 | SCM440 | 42CrMo4 |

| 20CrMnTi | 18XГT | SMK22 | |||

| 20Cr2Ni4 | 20X2H4A | ||||

| 20CrNiMo | 20CrNiMo2 | 20XHM | 8720 | SNCM220 | 21NiCrMo2 |

| 40CrNiMoA | 40XH2MA/ 40XHMA |

4340 | SNCM439 | 40NiCrMo6/ 36NiCrMo4 |

|

| 20CrNi2Mo | 20NiCrMo7 | 20XH2MA | 4320 | SNCM420 | |

Difference Between Helical Gear and Herringbone Gear

Helical and herringbone gears are both used in mechanical power transmission, offering smooth and quiet operation, but they differ significantly in design, performance, and application. Below is a concise comparison:

Key Differences

- Tooth Design

- Helical Gear: Single helix teeth (left- or right-hand).

- Herringbone Gear: Symmetrical double helix (left- and right-hand combined).

- Thrust Force

- Helical Gear: Generates axial thrust, requiring specialized bearings.

- Herringbone Gear: Symmetrical design cancels axial thrust.

- Helix Angle

- Helical Gear: Limited to 20–25° due to thrust.

- Herringbone Gear: Up to 45°, enhancing performance.

- Power Transmission

- Helical Gear: Axial thrust limits torque capacity.

- Herringbone Gear: Higher torque with no axial force.

- Manufacturing Complexity

- Helical Gear: Simple and cost-effective.

- Herringbone Gear: Complex and expensive.

- Bearings

- Helical Gear: Needs radial + axial load bearings.

- Herringbone Gear: Only radial load bearings required.

- Applications

- Helical Gear: Automotive, general machinery.

- Herringbone Gear: Turbines, large gearboxes.

|

|

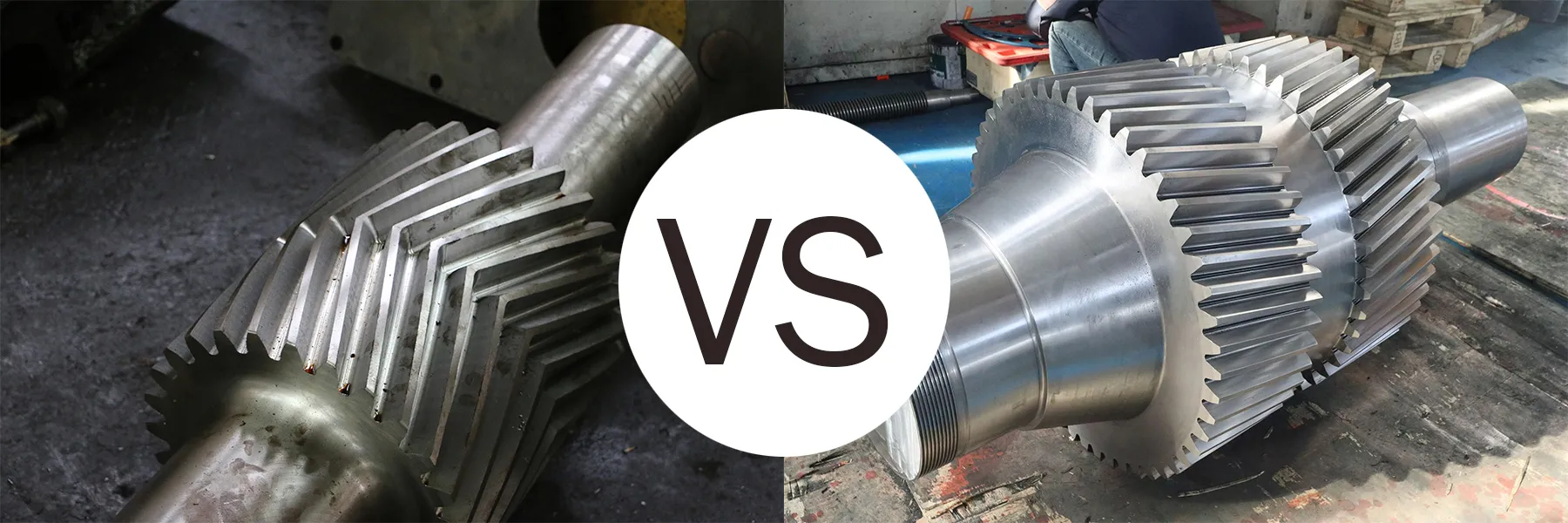

| Left: typical herringbone gear | right: typical double helical gear |

Comparison Table

| Aspect | Helical Gear | Herringbone Gear |

|---|---|---|

| Tooth Design | Single helix | Double symmetrical helix |

| Thrust Force | Present | None |

| Helix Angle | 20–25° | Up to 45° |

| Torque Capacity | Lower | Higher |

| Manufacturing | Simple/Cheap | Complex/Expensive |

| Bearings | Radial + Axial | Radial only |

| Applications | Automotive, Machinery | Turbines, Large Gearboxes |

Terminology Note

“Herringbone gears” typically lack a central groove, while “double helical gears” have one, but both eliminate axial thrust.

Helical gears are cost-effective and versatile for general use, while herringbone gears excel in high-torque applications despite higher costs.

Applications of Herringbone Gears

Herringbone gears shine in industries requiring robust, reliable power transmission. Here’s where you’ll find them across Italy and beyond:

- Heavy Machinery: In Milan, a hub of industrial innovation, herringbone gears power large machine tools and presses, ensuring efficiency in manufacturing plants.

- Marine Propulsion: In Venice, famous for its maritime heritage, these gears are integral to ship gearboxes, delivering reliable torque for vessel propulsion.

- Automotive Industry: In Bologna, a cornerstone of Italy’s automotive sector, herringbone gears enhance gearboxes and differentials, boosting vehicle performance.

- Energy Sector: In Florence, known for its engineering prowess, herringbone gears drive wind turbines and gas turbines, supporting sustainable energy solutions.

From industrial powerhouses to cutting-edge technology, herringbone gears play a vital role in keeping Italy’s economy moving.

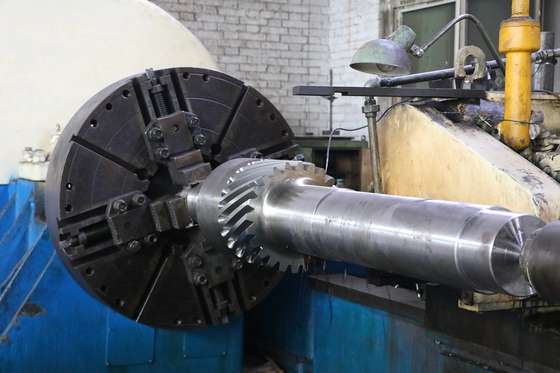

Manufacturing Herringbone Gears

Producing herringbone gears is no simple task. Their complex V-shaped design poses challenges that standard gear-cutting machines can’t handle—traditional hobbing cutters risk interfering with the opposite half of the gear. Specialized equipment, like the Sykes gear shaper or advanced CNC machines, is required to achieve precision. Modern innovations, such as 3D printing, have also made it possible to create lightweight, accurate herringbone gears. At FMP, we leverage state-of-the-art technology to overcome these challenges, ensuring every gear meets the highest standards.

Related Herringbone Gear Products

|

|

|

|

|

|

FMP Company: Your Herringbone Gear Experts

At FMP Company, we pride ourselves on being a leading manufacturer of helical gears, with a special focus on herringbone gears. Whether you’re in Milan, Venice, Florence, or Bologna, our products power industries ranging from automotive to marine and energy. We offer a wide range of helical gear solutions, and our herringbone gears are crafted to deliver exceptional performance in high-torque environments.

Looking for a specific herringbone gear? We provide customized solutions tailored to your needs. If you don’t see the model you require in our product list, don’t worry—it may not be uploaded yet. Simply email us with your specifications, and our skilled engineers will respond within 24 hours with a personalized solution. Contact us today to explore how FMP can elevate your machinery with top-quality herringbone gears.

Herringbone gears are a testament to engineering ingenuity, offering unmatched strength and efficiency for high-torque applications. At FMP Company, we’re committed to delivering these advanced gears to clients across Italy and beyond. Reach out to us via email to discuss your needs—our team is ready to provide the perfect gear solution within 24 hours. Let FMP be your partner in precision engineering!