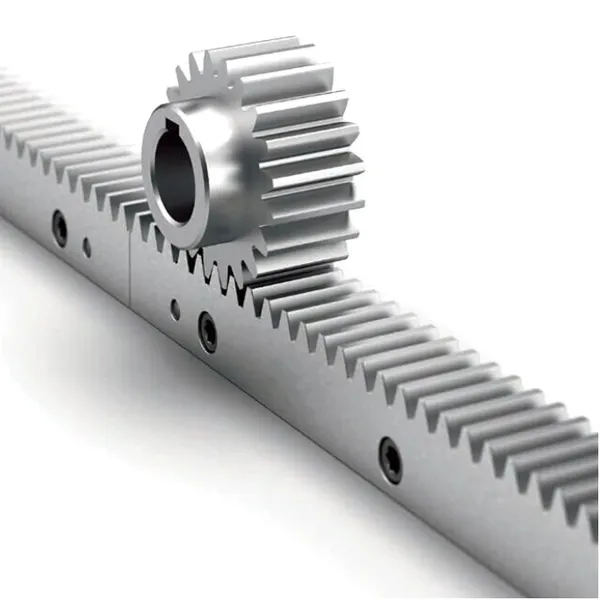

Helical Gear Rack(Finish Milled&Shaped)

| Precision Grade: (JIS Grade 5) 7e25 | Hardening: Tooth area carburized(HRC42-48) |

| Material:(S45C Medium Carbon Steel)C45 | Side Ground: Included |

| Type: Helical Rack | Pressure Angle: 20° |

| Treatment of Teeth: Milled | Right helix angle: 19°31′42″ |

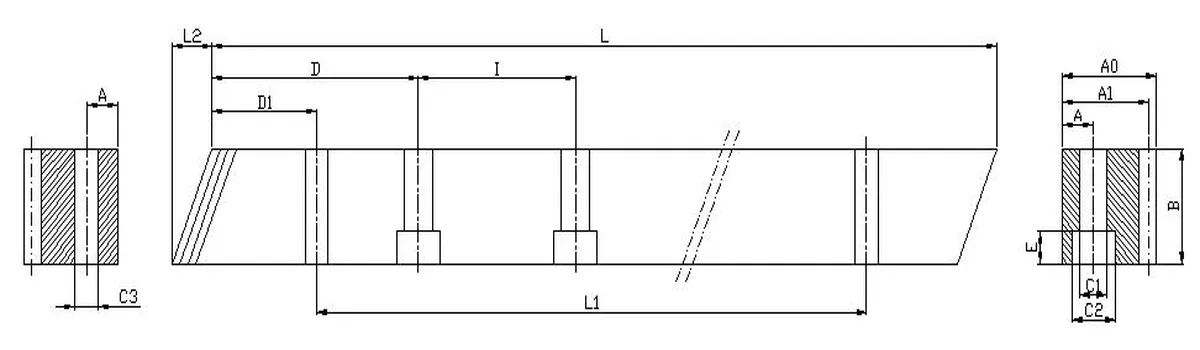

Helical Gear Rack Specification:

| Module | L | L2 | Tooth No. | B | A0 | A1 | D | I | Hole No. | A | C1 | C2 | E | D1 | I1 | C3 | Pitch Error /300mm |

| 1 | 1000.00 | 3.14 | 300 | 15 | 15 | 14 | – | – | – | – | – | – | – | – | – | – | 0.02 |

| 1.5 | 1000.00 | 6.7 | 200 | 19 | 19 | 17.5 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 0.03 |

| 2 | 1000.00 | 8.5 | 150 | 24 | 24 | 22 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 0.031 |

| 2.5 | 1000.00 | 8.5 | 120 | 24 | 24 | 21.5 | 62.5 | 125 | 8 | 9 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 0.033 |

| 3 | 1000.00 | 10.3 | 100 | 29 | 29 | 26 | 62.5 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 | 0.035 |

| 4 | 1000.00 | 13.8 | 75 | 39 | 39 | 35 | 62.5 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.0 | 7.7 | 0.038 |

| 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.5 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 | 0.04 |

| 6 | 1000.00 | 20.9 | 50 | 59 | 49 | 43 | 62.5 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 | 0.042 |

| 8 | 1000.00 | 28.7 | 36 | 79 | 79 | 71 | 60 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 19.7 | 0.045 |

| 10 | 1000.00 | 35.11 | 30 | 99 | 99 | 89 | 62.5 | 125 | 8 | 32 | 33 | 48 | 32 | 125.0 | 750.0 | 19.7 | 0.052 |

Helical Gear Rack and Pinion Product Information

| Process | Machining, Forging, Casting, Cutting |

| Material | C45(1045), A3(low carbon steel), 40Cr, 20CrMnTi, 42CrMo, Cast iron, Ductile iron, Copper, Stainless steel, and so on, as you requested |

| Heat Treatment | High-frequency quenching, Carburizing, Shot peening, Quenching, and Tempering, Nitriding |

| Surface Treatment | I am blacking, Hot-dip Galvanizing, Hard Chrome Plating, Zinc Plating, Electroplating, Nickel plating, Sandblasting, Color painting, Dacromet coating, Powder coating, and customer requirements. |

| Performance | Long lifespan, High precision, High wear resistance, High strength, Low noise, Smooth and steady, Fatigue strength |

| Model | ANSI, DIN, JIS Standard, Non-Standard, Spur Gears, Helical Gears, Straight Bevel Gears, Spiral Bevel Gears, Worm Gears, Gear Racks |

| Packaging | Products are carefully packaged, Inner plastic bags and outer carton boxes or customer requirement; after long-distance transport or long time store, open the package; brand new, no damage, no rust. |

Applications of Helical Gear Rack

Helical rack and pinion drives are used in a variety of applications including axis drives, mobile gantries and columns, pick-and-place robots, CNC routers, and material handling systems where precise positioning and repeatability are required. These drives can also handle heavy load capacities and duty cycles with ease. Industries include material handling, automation, automotive, aerospace, machine tools, and robotics.