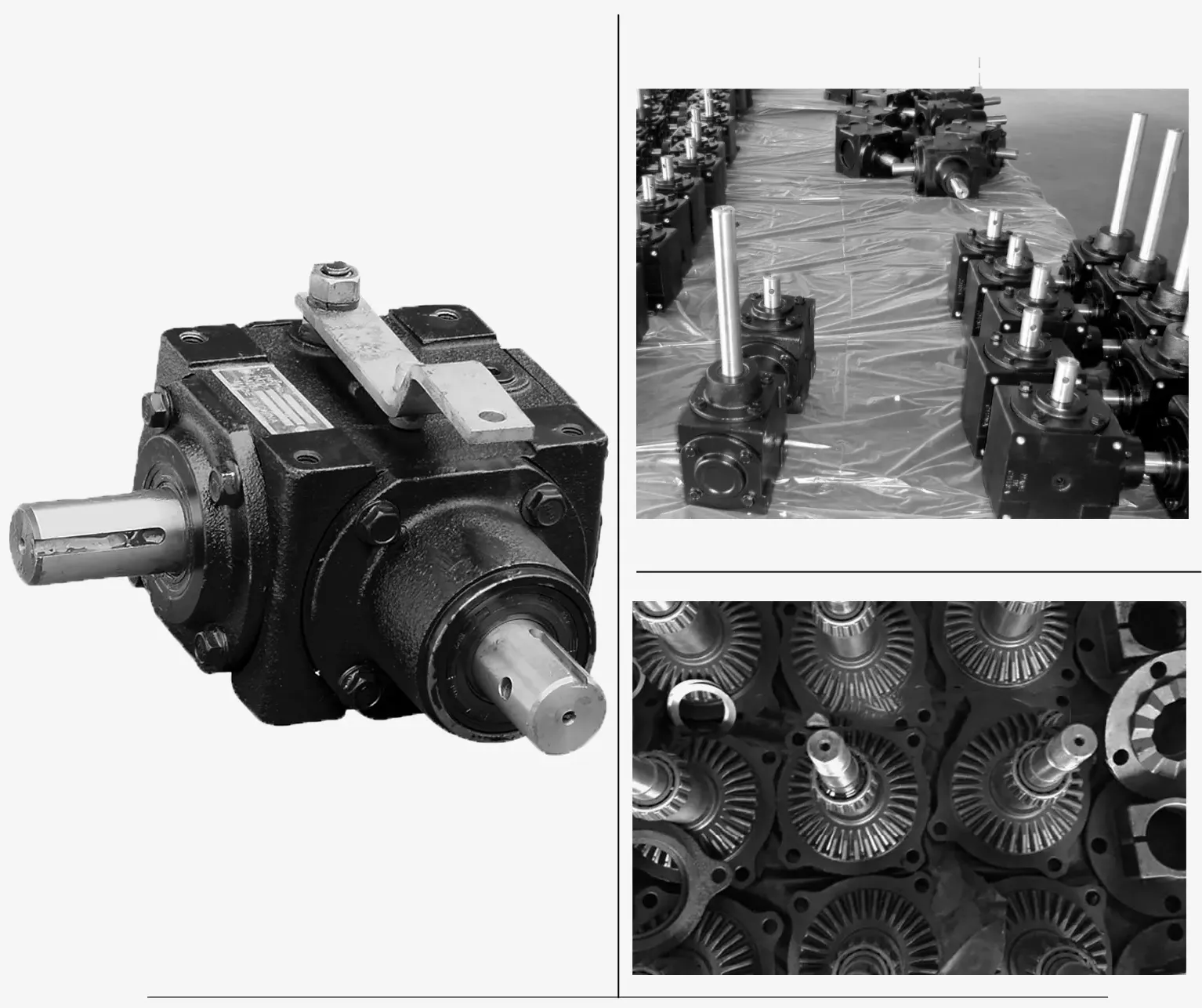

Grain Transportation Gearbox FMP-1002 Specifications

| Product Name | Grain transportation gearbox |

| Model | EP-1002 |

| Color | Customization |

| Material | HT250 for housing, 20CrMnTi for gear shaft. |

| Used | Grain transportation |

Key Components of Grain Transportation Gearbox FMP-1002

The Grain Transportation Gearbox FMP-1002 is designed to provide optimal performance for grain transportation systems, such as conveyors and augers. Key components of this gearbox include:

1. Housing:

- Material: Typically made of high-quality cast iron or durable alloys, the housing serves as the main protective enclosure for the internal components.

- Function: Provides structural support and protection against external wear and tear, while ensuring proper alignment of internal gears.

2. Gears:

- Helical Gears: Commonly used for their efficiency and quieter operation, helical gears offer smoother transitions between teeth, reducing noise and enhancing the overall performance of the gearbox.

- Bevel Gears: Used in some designs to change the direction of the power flow, bevel gears allow the gearbox to function at an angle, enabling versatile applications.

- Material: Gears are often made from hardened steel or other durable materials to withstand the high torque and mechanical stresses encountered during operation.

3. Shafts:

- Input and Output Shafts: These shafts are the primary mechanical link between the motor, gearbox, and the grain transportation system.

- Material: Hardened steel shafts ensure strength and longevity under heavy load conditions.

4. Bearings:

- Roller Bearings or Ball Bearings: Bearings reduce friction between rotating parts, ensuring smooth operation and minimizing wear.

- Function: Bearings support the rotating components, allowing the gears and shafts to turn freely and efficiently while maintaining proper alignment.

5. Seals and Gaskets:

- Function: Prevent leakage of lubricant and protect internal components from contaminants like dust, dirt, and moisture. Seals help maintain the gearbox’s efficiency and prevent premature wear.

By combining these components, the FMP-1002 Grain Transportation Gearbox provides reliable and efficient power transmission for grain conveying systems, ensuring smooth and consistent operation even under heavy loads.

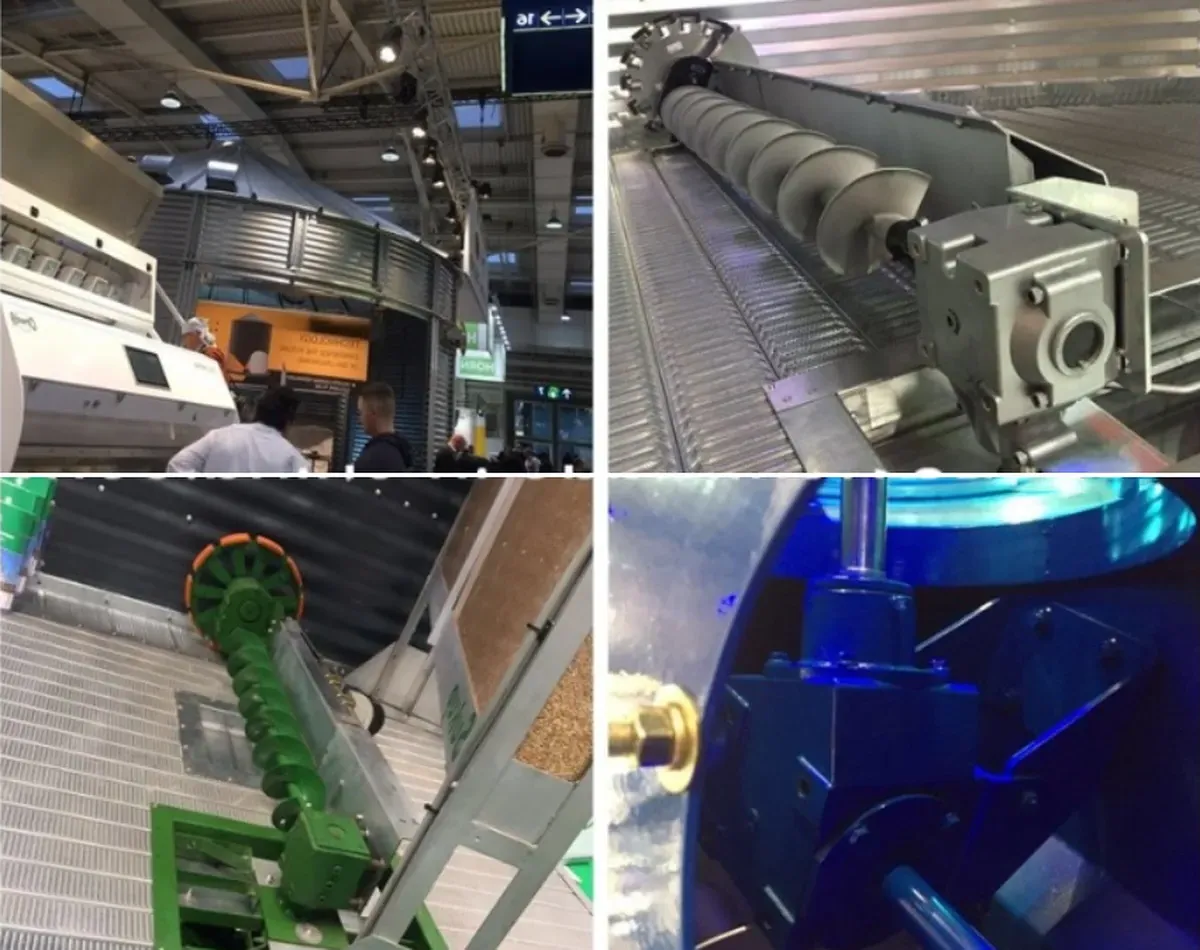

Applications of Grain Transportation Gearbox FMP-1002

Applications of Grain Transportation Gearbox FMP-1002

The Grain Transportation Gearbox FMP-1002 is engineered for optimal performance in various agricultural and industrial applications where the transportation of grain and other bulk materials is involved. Its reliable power transmission and durability make it ideal for the following key applications:

1. Grain Elevators

- Application: Used in grain elevators for lifting and moving grain from one level to another.

- Role: The gearbox transmits power from the motor to the elevator’s conveyor system, enabling the vertical transportation of grain within storage or processing facilities.

2. Conveyor Systems

- Application: Grain transportation gearboxes are essential in conveyor systems, which are commonly used for transferring grain across distances within processing plants, silos, or storage areas.

- Role: The gearbox powers the conveyor belt, ensuring smooth and consistent movement of grain over various distances and through different processing stages.

3. Augers and Screw Conveyors

- Application: Used in augers and screw conveyors for efficiently moving grain and other bulk materials in farming and industrial settings.

- Role: The gearbox drives the screw mechanism, allowing for the transportation of grain from one container to another or between different stages of the processing line.

4. Grain Harvesting Equipment

- Application: Integrated into combine harvesters and other grain harvesting machines, the gearbox facilitates the transfer of harvested grain from the collection area to the storage compartment or bin.

- Role: The gearbox helps in powering the conveyors, augers, or other grain transportation components in the harvester, ensuring quick and efficient unloading of grain.

5. Grain Storage Systems

- Application: Used in grain storage systems, particularly for the transportation of grain into silos or storage bins.

- Role: The gearbox powers conveyors or auger systems, ensuring smooth transfer and storage of grain within the facility.

The FMP-1002 Grain Transportation Gearbox is a versatile and efficient component widely used across the agricultural sector, ensuring smooth, consistent, and reliable transportation of grain and bulk materials in various systems.

About FMP

Headquartered in Italy, FMP is a prominent manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, with a primary focus on the agricultural machinery sector. Renowned for its precision engineering, innovative solutions, and consistent reliability, FMP has established a strong reputation as a trusted partner in both agricultural and industrial markets. Our diverse portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide range of other critical components, each meticulously designed to meet the specific demands of various applications.

At FMP, we recognize that every client faces unique challenges. This understanding drives our commitment to delivering tailored solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution not only meets their specific needs but also optimizes performance and maximizes value. Our dedication to timely, professional responses and expert guidance ensures that every inquiry is handled with precision, consistently delivering optimal results.

We place a strong emphasis on transparent, ongoing communication throughout the entire product development cycle. Our dedicated team collaborates closely with clients to fully understand their requirements and provide valuable insights and recommendations to achieve the best outcomes. Whether designing cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to exceed client expectations, providing exceptional service and results with every project.

At the core of FMP’s operations is a steadfast commitment to quality. We adhere to the highest manufacturing standards and implement stringent quality control processes to ensure that each product not only meets but exceeds industry benchmarks. This unwavering focus on excellence, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients in nearly 30 countries worldwide.

At FMP, we are always eager to foster global partnerships by offering expert advice and customized solutions that address the ever-evolving needs of our clients. We strive to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you are looking for innovative solutions for a new initiative or ongoing support for an existing system, FMP is ready to help you overcome technical challenges and ensure your continued success.

Author: CX