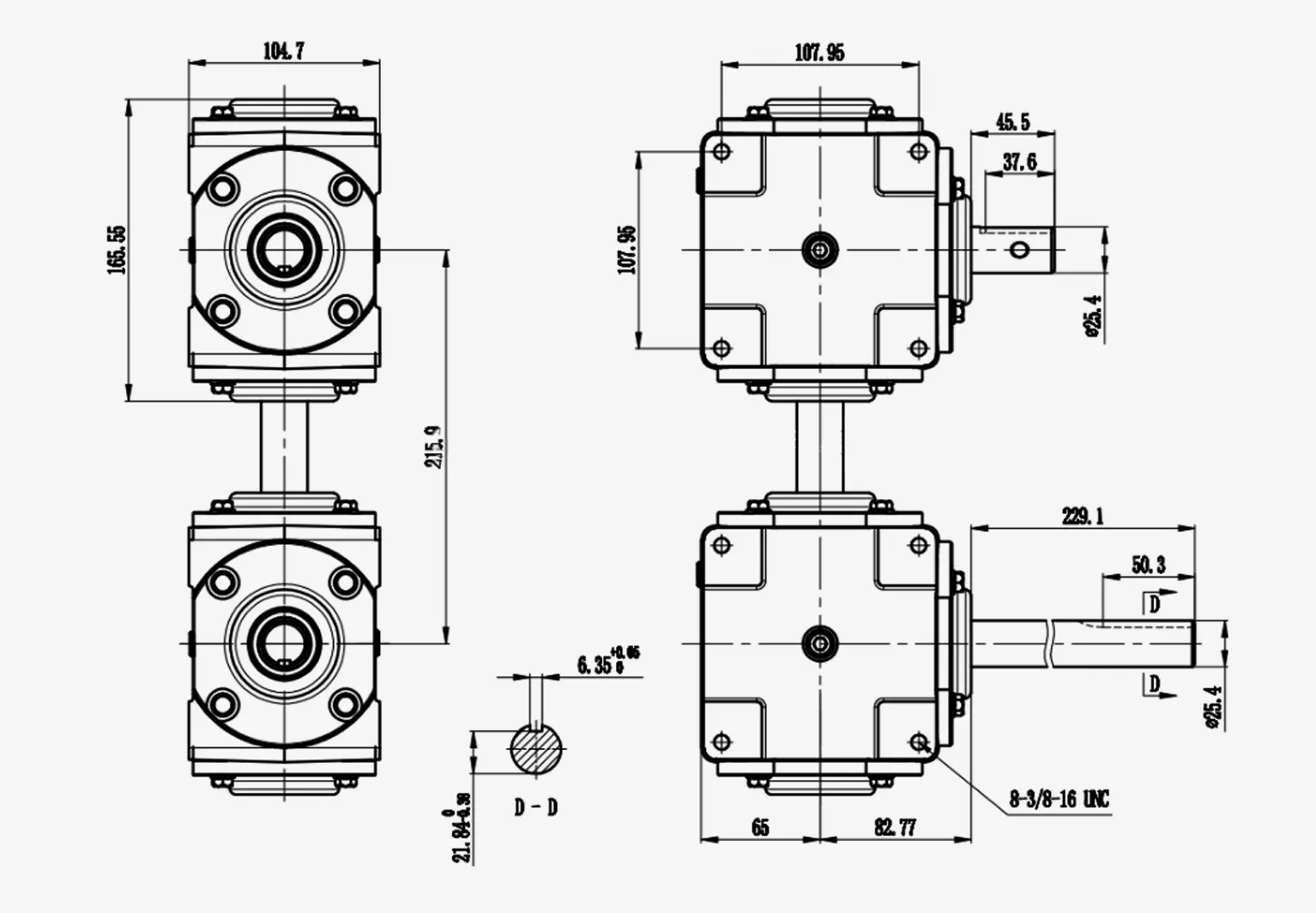

Grain Auger Gearbox FMP-2390 Specifications

| Product Name | Grain auger gearbox FMP-2390 |

| Material | Housing as HT250, Shaft as 20CrMnTi |

| Color | Dark or Red or as customized |

| Type | Bevel gear |

| Ratio | 1:1 |

| Bearing | QC or C&U or NTN |

| Warranty | one and half year |

| Used | grain storage |

Applications of Grain Auger Gearbox for Grain Storage and Transportation

Grain auger gearboxes play a critical role in the efficient movement and handling of grains during storage and transportation processes. The following are key applications of grain auger gearboxes in these sectors:

- Grain Storage Silos:

- Grain Elevators: The gearbox powers the augers used in grain elevators, lifting grain to various storage levels within silos. The efficient movement of grain is essential to prevent clumping or damage, ensuring optimal storage conditions.

- Unloading Systems: Auger gearboxes are integral to unloading grain from storage silos into trucks, conveyors, or other transport systems. Their precision ensures smooth and consistent flow of grain, preventing blockages or delays.

- Grain Handling Facilities:

- Conveyor Systems: In grain handling facilities, auger gearboxes are used to power screw conveyors that move grain across various sections of the processing plant. They ensure grain is transported swiftly between storage, cleaning, and milling areas.

- Drying Systems: Grain auger gearboxes are used in drying systems, where augers move grain through drying chambers, allowing for consistent airflow and moisture reduction. This ensures that the grain remains in optimal condition for long-term storage.

- Grain Transport to Market:

- Truck Loading: Auger gearboxes are essential in truck loading stations, where they are used to move grain from storage facilities or transport silos into trucks for further distribution. The gearbox ensures smooth, fast, and controlled grain transfer.

- Bulk Grain Handling: In facilities dealing with large-scale bulk grain handling, auger gearboxes provide the necessary torque to transport grain efficiently, minimizing spillage and waste while maximizing throughput.

- Grain Processing and Milling:

- Cleaning Systems: Grain augers powered by gearboxes are used in cleaning systems to move grain through various sieving, sorting, and separating machines. These augers help remove unwanted debris and ensure the grains are ready for milling or further processing.

- Milling Units: Auger gearboxes also support grain transport through milling units where grain is ground into flour or processed for other uses. They enable the consistent feeding of grain into grinders or crushers.

- On-Farm Use:

- Farm Augers: For grain transport from harvesters to storage bins or trailers, auger gearboxes are commonly used on farms. The gearboxes provide the necessary torque and control for the augers, making them effective for grain transfer during harvest seasons.

- Grain Bin Systems: Auger gearboxes in grain bins facilitate the movement of grain into different areas of the farm or storage facilities, ensuring that grains are not damaged during the transfer process.

By utilizing grain auger gearboxes, agricultural and storage facilities can streamline operations, reduce operational costs, and maintain high standards of grain quality.

Key Components of Grain Auger Gearbox

The grain auger gearbox is a critical component in agricultural and storage systems, as it ensures the efficient movement of grain through various processes, such as transport, storage, and milling. The key components of a grain auger gearbox are designed for durability, performance, and efficiency. Here are the primary components:

- Housing (Gearbox Casing):

- The outer casing or housing protects the internal components of the gearbox. Typically made from high-strength materials such as cast iron or durable steel, the housing ensures the gearbox can withstand the harsh conditions of agricultural environments, including exposure to dust, moisture, and extreme temperatures.

- Input Shaft:

- The input shaft is the component that receives power from the driving source (e.g., an electric motor, tractor PTO, or engine). It transfers rotational motion into the gearbox, which is then transmitted to the auger mechanism. The input shaft is designed to handle high rotational speeds and torque loads.

- Output Shaft:

- The output shaft is connected to the auger and transmits the rotational motion generated by the gearbox to the auger itself. It plays a vital role in ensuring the auger operates smoothly to move grain. The output shaft is usually designed with heavy-duty bearings to support the load and prevent wear and tear during long operating hours.

- Gears:

- The gears inside the gearbox are the primary components responsible for converting the input torque and speed into the desired output. Common types of gears used in grain auger gearboxes include:

- Helical Gears: Provide smooth and quiet operation with improved efficiency.

- Spur Gears: Simpler and more cost-effective, but typically noisier than helical gears.

- Bevel Gears: Used for changing the direction of rotation, commonly found in right-angle gearboxes.

- The choice of gear type depends on the required torque, speed, and durability.

- The gears inside the gearbox are the primary components responsible for converting the input torque and speed into the desired output. Common types of gears used in grain auger gearboxes include:

- Bearings:

- Bearings support the rotating shafts within the gearbox, minimizing friction and ensuring smooth operation. They are critical for maintaining stability and reducing wear, especially under heavy loads. High-quality bearings are chosen to extend the lifespan of the gearbox and reduce the need for maintenance.

The key components of a grain auger gearbox work together to provide efficient, reliable performance in grain handling and transportation. Proper selection, maintenance, and lubrication of these components are essential to ensure optimal functionality and a long service life, making the grain auger gearbox a vital part of modern agricultural and storage operations.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in designing, developing, and producing high-performance gearboxes, with a primary focus on the agricultural machinery sector. Known for its precision engineering, innovative solutions, and steadfast reliability, FMP has earned a reputation as a trusted partner within both agricultural and industrial markets. Our comprehensive portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide range of essential components, all meticulously crafted to meet the specific demands of various applications.

At FMP, we understand that every client faces unique challenges. This is why we specialize in delivering tailored solutions, whether for individual components or fully integrated systems. Through close collaboration with our clients, we ensure that each solution not only meets their needs but also optimizes performance and maximizes value. Our commitment to swift, professional responses and expert guidance guarantees that every inquiry is addressed with precision, ensuring the best outcomes every time.

We prioritize clear, continuous communication throughout the entire product development cycle. Our dedicated team works closely with clients to thoroughly understand their requirements and provide valuable insights and recommendations to achieve optimal results. Whether designing state-of-the-art products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our mission is to consistently exceed client expectations, providing exceptional service and results with every project.

Quality is at the heart of FMP’s operations. We uphold the highest manufacturing standards and implement rigorous quality control measures to ensure that each product meets, and often exceeds, industry benchmarks. This commitment to excellence, along with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is always eager to cultivate global partnerships, offering expert advice and customized solutions that address the evolving needs of our clients. We strive to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you require innovative solutions for a new initiative or ongoing support for an existing system, FMP is ready to help you overcome technical challenges and ensure your continued success.

Author: CX