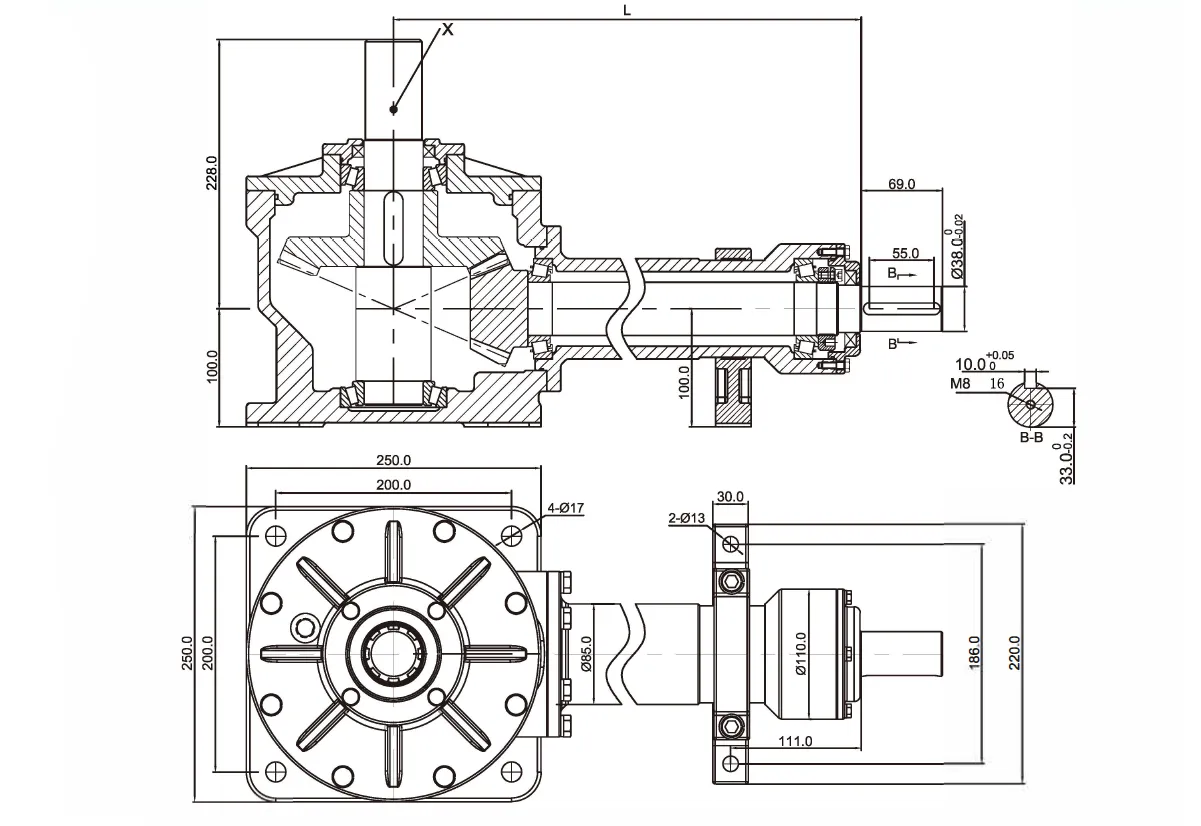

Grader Driven Rake Gearbox FMP100 Dimensions

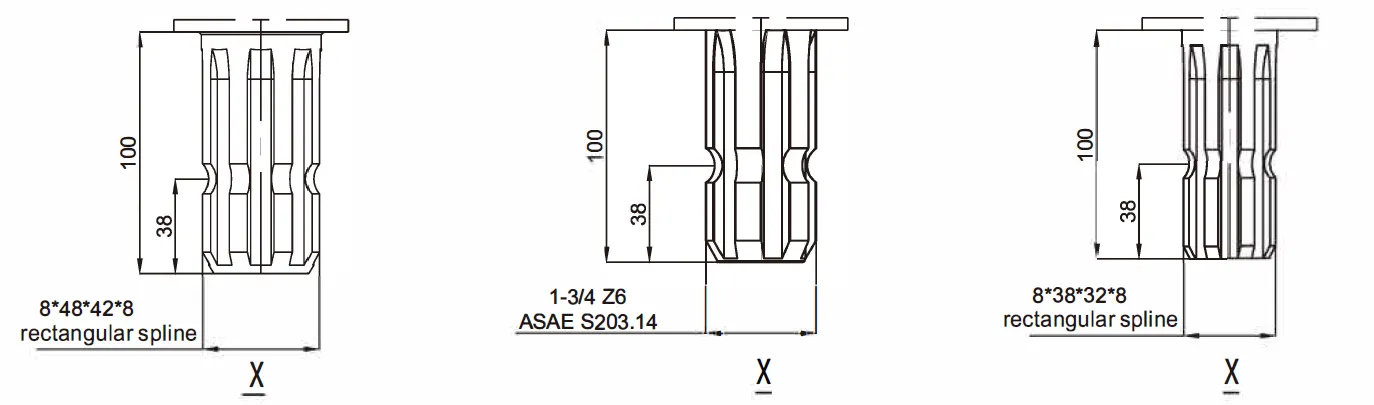

Grader Driven Rake Gearbox FMP100 Shaft Dimensions

Grader Driven Rake Gearbox FMP100 Technical Data

| i | Suitable | Rpm input | Rpm output | KW(Nom) | KW(Max) | L | ||

| r/min | r/min | hp | hp | mm | ||||

| Speed increase | 1 :2.31 | Rotary Tillers, etc | 540 | 1250 | 100 | 140 | 397 | 226 |

| Remark: If you have any special require feel free let me know, we also accept custom. | ||||||||

Grader Driven Rake Gearbox FMP100 Working Principle

The Grader Driven Rake Gearbox FMP100 is designed to drive the rake mechanism of a grader, typically used in agricultural machinery like windrowers or rakes. Here’s an overview of its working principle:

Power Input via PTO Shaft

The working of the Grader Driven Rake Gearbox FMP100 starts with the power input from a PTO (Power Take-Off) shaft. This shaft connects the gearbox to a tractor or other machinery. The PTO transmits mechanical power generated by the engine to the gearbox, which in turn drives the rake mechanism.

Gearbox Reduction

Once the PTO shaft powers the Grader Driven Rake Gearbox FMP100, the gearbox performs a gear reduction. This process converts the high rotational speed of the PTO into a slower, higher-torque output suitable for driving the rake’s components. The reduction is achieved through a set of internal gears, which step down the input speed to a more manageable speed for the rake.

Distribution of Power to the Rake

The gearbox then distributes the power through its output shaft, driving the rake components, such as the wheels, tines, and rotation arms. Depending on the rake’s design, the gearbox may control the movement of several individual rake sections or a central rotating system.

Adjustment Mechanisms

Some versions of the Grader Driven Rake Gearbox, including the FMP100, include adjustment features that allow operators to fine-tune the rake’s speed or operation mode. This is often achieved by adjusting the output shaft’s gear ratios, allowing for the rake to perform different tasks like windrowing or even soil leveling, depending on the application.

Torque Transmission and Control

Throughout the process, the Grader Driven Rake Gearbox FMP100 ensures that the torque is transmitted smoothly to the rake mechanism, providing efficient operation. The gearbox also manages the distribution of power, ensuring the rake operates evenly and consistently, even under varying field conditions or loads.

This working principle allows the Grader Driven Rake Gearbox FMP100 to provide optimal power transfer, consistent rake operation, and high efficiency, making it a reliable choice for agricultural applications.

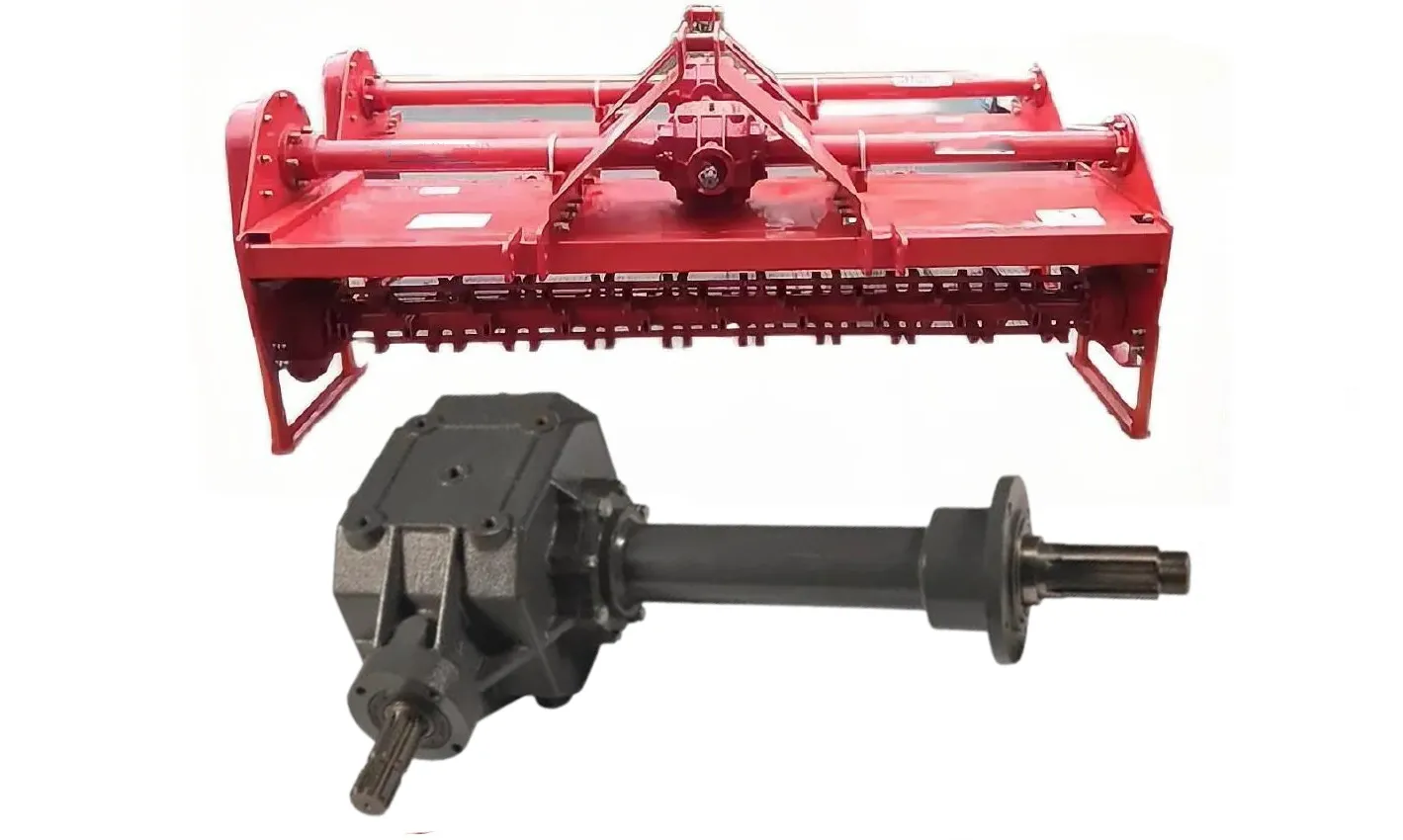

Grader Driven Rake Gearbox FMP100 Common Applications

The Grader Driven Rake Gearbox FMP100 is primarily used in agricultural and industrial machinery, particularly in applications where efficient and durable power transfer is required to operate rake systems. Below are the common applications of the FMP100 gearbox:

Windrowers (Hay Rakes)

- Purpose: The FMP100 gearbox is often used in windrowers to drive the rake mechanism that collects hay, straw, or other crops into rows (windrows). This helps in efficient drying, handling, and later harvesting.

- How It Works: The gearbox transfers power from the tractor’s PTO to the rake, ensuring that the rake moves efficiently through the field and forms even windrows for further processing.

Hay and Straw Rakes

- Purpose: The gearbox is used in hay and straw rakes to gather the cut hay or straw into neatly organized piles or windrows for efficient collection and transportation.

- How It Works: In this application, the gearbox ensures smooth and consistent operation of the rake tines, improving crop handling by reducing damage to the material and increasing efficiency.

Rotary Rakes

- Purpose: In rotary rakes, which use rotating wheels or tines to gather and arrange hay or straw, the FMP100 gearbox is responsible for transmitting power to the rotating elements.

- How It Works: The gearbox’s reduction system allows the PTO input from the tractor to be efficiently converted into a slower, higher-torque output that drives the rake’s rotating arms.

Agricultural Graders

- Purpose: Grader-driven rakes equipped with the FMP100 gearbox are used in agricultural grading applications where soil or crop residue needs to be leveled or spread evenly across fields.

- How It Works: The gearbox drives the rake mechanism to evenly distribute materials over a large area, aiding in the preparation of fields for planting or other agricultural processes.

Tedding Machines

- Purpose: Tedding machines are used to spread out and aerate hay or grass for faster drying. The FMP100 gearbox is used in these machines to power the rake arms or rotors.

- How It Works: The gearbox drives the rotating arms, helping to fluff and spread the hay or grass evenly across the field, ensuring proper aeration and preventing clumping.

In all these applications, the Grader Driven Rake Gearbox FMP100 contributes significantly to the performance, reliability, and efficiency of agricultural machinery, making it an essential component in modern farming and land management.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX