|

|

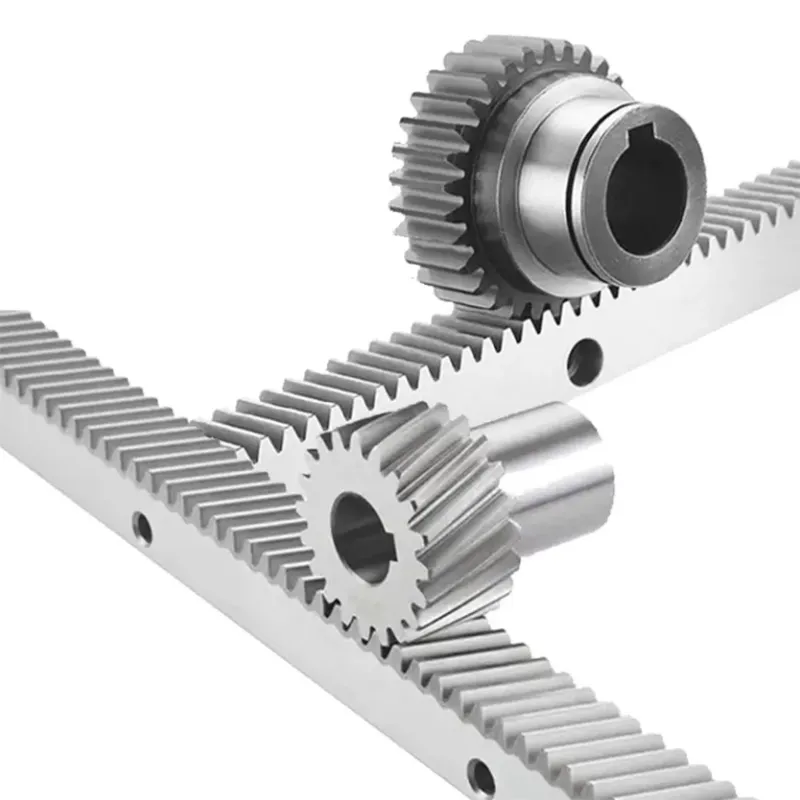

Rack and Pinion Gear Material

As for the materials of racks and pinions, strength, abrasion resistance, and absorbency are considered. Carbon steel is the most common material used to make racks and pinion steel.

- This material is excellent for most settings and usage scenarios.

- The relative strength of the rack tooth combined with the pinion makes this material effective.

- Additionally, the material is well-suited for heat-treating to increase strength, allows for the insertion of threaded or bolt holes, upholds dimensional stability, and may be straightened if required.

| Aluminum | Aluminum is a bluish, silver-white, malleable, ductile, light, trivalent, metallic element with good electrical and thermal conductivity, high reflectivity, and oxidation resistance. It is lighter than steel but not as strong. |

| Brass | Brass has good strength, high-temperature ductility and cold flexibility, electrical conductivity, corrosion resistance, bearing properties, and low magnetic permeability. |

| Bronze | Bronze is a copper base alloy that consists of copper as the primary alloying metal and one or more other metals, such as tin, zinc, or phosphorus. Silicon bronze is a typical bronze alloy. |

| Cast Iron | Cast iron is a very durable iron alloy with high amounts of carbon. Types include ductile iron, gray iron, and white cast iron grades. Differences in grades are due to variations in composition and processing. |

| Carbon / Alloy Steel | Steel is a commercial iron that contains carbon in any amount up to about 1.7 percent as an essential alloying constituent. Many grades of carbon and alloy steel are available. They may require a coating to protect against corrosion, however. |

| Hardened Steel | Steel may be hardened in several ways. These include a variety of quenching techniques in oil and water, passing the steel through induction chambers, etc. Quickly cooling steel during processing freezes, traps, and packs the carbon atoms inside the shrunken iron crystals, producing a rigid and brittle metal. Although challenging, it cannot absorb much shock or impact without breaking. |

| Stainless Steel | Stainless steel is chemical and corrosion-resistant and can have relatively high-stress ratings. Most stainless steels cannot be hardened to the same degree as carbon steels. |

| Acetal | Acetal is a stable plastic material with inherent self-lubricating properties that can be enhanced with lubricating fillers. |

| Delrin | Delrin is an engineered plastic with toughness, stiffness, wear and abrasion resistance, and low frictional characteristics. |

| Nylon | Nylon, comprising several grades of polyamides, is a general-purpose material in wide use. It is challenging and resistant and has good pressure ratings. |

| Polycarbonate | Polycarbonate is an extremely tough polymer that can be machined to close tolerances. Lubrication is sometimes needed, as the wear properties of polycarbonate are not as good as some other polymers. |

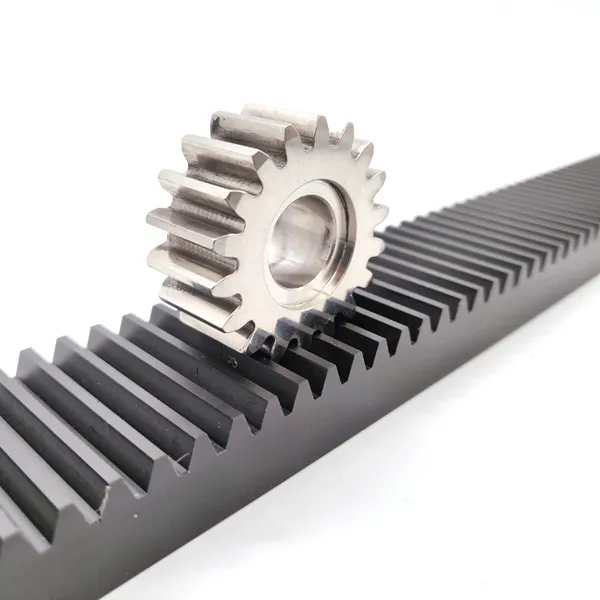

Gear Rack Application

Mainly used in various mechanical transmission systems, such as automated machinery, CNC machine tools, building materials workshops, manufacturing plants, machinery repair shops, construction projects, etc.