Forklift Tilt Hydraulic Cylinder

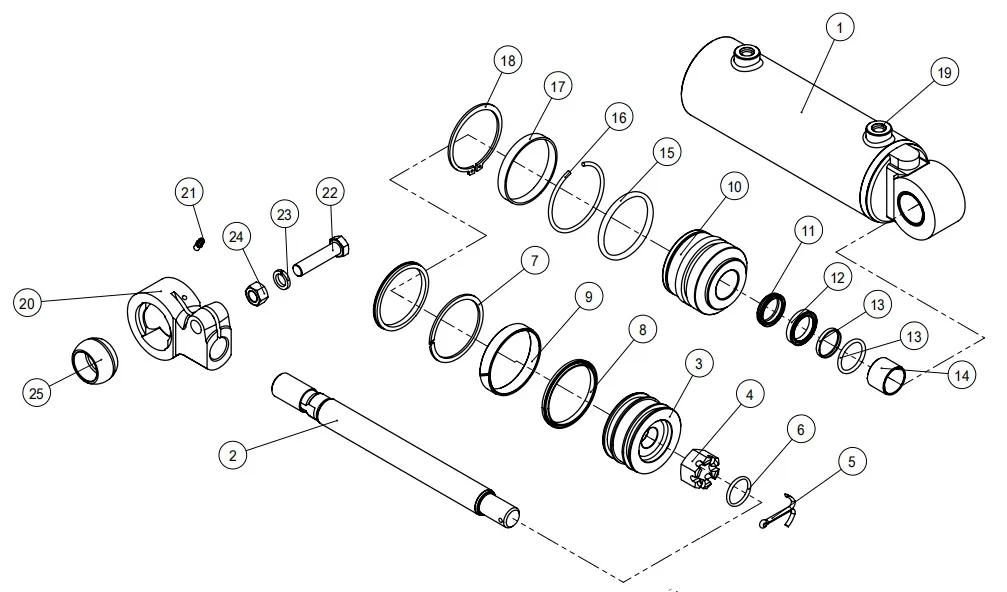

Forklift Tilt Hydraulic Cylinder Parts:

|

1

|

Cylinder Housing assy

|

10

|

Guide Bush

|

18

|

Circlips For Shaft

|

|

2

|

Piston Rod

|

11

|

Dust Wiper

|

19

|

Plug

|

|

3

|

Piston

|

12

|

U-Ring

|

20

|

Clevis

|

|

4

|

Hex Nut

|

13

|

Rod Seal

|

21

|

Grease Nipple

|

|

5

|

Cotter Pins

|

14

|

Du Bush

|

22

|

Bolt

|

|

6

|

O-Ring

|

15

|

O-Ring

|

23

|

Spring Washers

|

|

7

|

Back-Ring

|

16

|

Round Wire

|

24

|

Nut

|

|

8

|

Hole Seal

|

17

|

Key Ring

|

25

|

Spherical Bearing

|

|

9

|

Wear-Ring

|

Forklift Tilt Hydraulic Cylinder Dimensions:

|

|

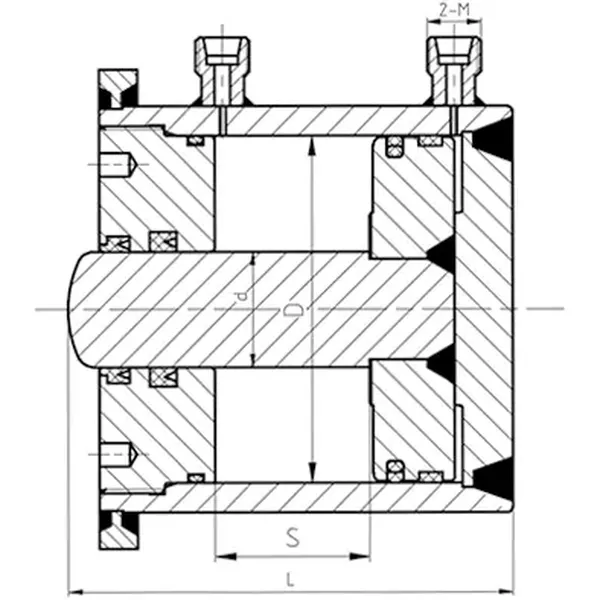

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| TILT CYLINDER | QA20V500-405000-000 | Φ60 | Φ30 | 32 | 109 | 18MPa | 2-M14*1.5 | 3.4kg |

|

|

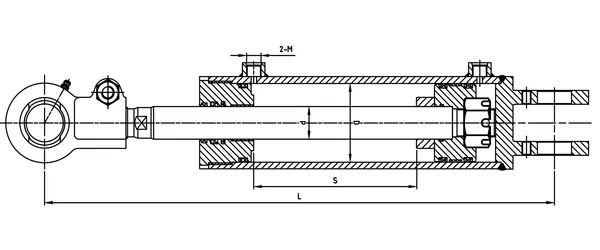

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| TILT CYLINDER | S16N450-600000-001Z | Φ63 | Φ25 | 55 | 368 | 18.1MPa | 2-G1/4 | 8.2kg |

| TILT CYLINDER | RTE35M300-600000-500 | Φ85 | Φ35 | 180 | 565 | 18.1MPa | 2-M16*1.5 | 17kg |

| TILT CYLINDER | A15N450-600000AZ | Φ65 | Φ25 | 109 | 514 | 18.1MPa | 2-G1/4 | 11.6kg |

|

|

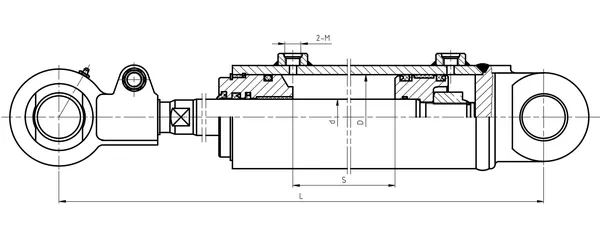

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| TILT CYLINDER | A30M300-600000-000B | Φ70 | Φ30 | 156 | 453 | 18.1MPa | 2-G1/4 | 12kg |

| TILT CYLINDER | A35M300-600000-000C | Φ80 | Φ30 | 156 | 456.5 | 18.1MPa | 2-G1/4 | 13kg |

| TILT CYLINDER | A45M300-600000Z | Φ100 | Φ40 | 193 | 498 | 18.1MPa | 2-M16*1.5 | 22kg |

What is the difference between lift cylinder and tilt cylinder?

Lift Cylinder

A lift cylinder is primarily designed to provide vertical movement by lifting and lowering heavy loads. It operates by moving in a straight, linear direction, usually up or down, to raise or lower equipment, machinery, or materials. The lift cylinder is essential in applications where a vertical lifting motion is required, such as in cranes, forklifts, excavators, and loaders. It is often used to move heavy objects or raise components such as booms, lift arms, or containers. The lift cylinder plays a critical role in providing lifting force, making it a key component in construction machinery, material handling systems, and agricultural equipment that involves heavy-duty lifting tasks.

Tilt Cylinder

A tilt cylinder, on the other hand, is designed to create rotational or angular movement, enabling the tilting of an object or mechanism around a horizontal axis. Instead of lifting or lowering, a tilt cylinder adjusts the angle of a load or attachment, allowing it to tilt forward or backward. This type of cylinder is commonly used in applications where precise angle adjustments are needed, such as controlling the tilt of a loader bucket, a snowplow, or the bed of a dump truck. Tilt cylinders are often found in equipment like skid-steer loaders, excavators, and tractors, where tilting is necessary to position tools, attachments, or materials accurately. These cylinders typically work in conjunction with lift cylinders to provide full-range movement, where lifting and tilting motions are both required to complete the task.

Advantages of Forklift Tilt Hydraulic Cylinder

Enhanced Precision and Control

The forklift tilt hydraulic cylinder provides precise control over the tilting angle of the forklift’s mast or attachments. This allows operators to adjust the angle of the load for optimal stability, ensuring that heavy or delicate loads are positioned safely and efficiently. With the ability to tilt the mast forward or backward, operators can improve their ability to stack, unstack, or maneuver loads in tight spaces, increasing both the safety and productivity of the forklift operations.

Increased Load Handling Versatility

One of the key advantages of the forklift tilt hydraulic cylinder is its ability to improve load handling versatility. It enables operators to adjust the forklift’s mast to different angles, making it easier to handle a variety of load types and sizes. For instance, it facilitates loading and unloading of materials from trucks, adjusting the mast angle to accommodate different pallet heights or angles. This versatility is essential in environments with diverse material handling needs, such as warehouses, distribution centers, and manufacturing facilities.

Improved Stability and Safety

The tilt hydraulic cylinder contributes to enhanced stability and safety during forklift operations. By allowing the forklift mast to tilt backward, the cylinder helps to better balance heavy loads and prevent the risk of tipping or losing control of the load. Additionally, when tilting forward, it can help safely position the load closer to the ground during handling, minimizing the risk of accidents caused by unbalanced loads or improper load positioning. This added stability ensures the safety of both the operator and the surrounding environment, reducing potential damage to goods, equipment, and the work area.

About FMP

FMP is a specialized manufacturer of hydraulic cylinders, with a strong focus on research and production. Since its founding, the company has consistently concentrated on the development of hydraulic cylinders, evolving from producing a variety of products, such as harvesting and construction machinery, to specializing in agricultural tractor components. With over a decade of manufacturing expertise, management experience, and advanced production technology, FMP guarantees the highest quality in its products.

As the company has grown professionally, it has established a comprehensive machining production line, assembly line, and coating line. FMP is supported by a dedicated team of experienced management personnel, skilled mechanical designers, and highly trained technical workers. This ensures stable product quality, while efficiently controlling process continuity and overall production effectiveness.

FMP adheres to the core values of “Technological innovation driving progress, quality creating brands, craftsmanship ensuring quality, and building long-term win-win relationships.” The company remains committed to providing high-quality products while delivering superior customer service, always striving to meet the evolving needs of the market.

|

|

Author: CX