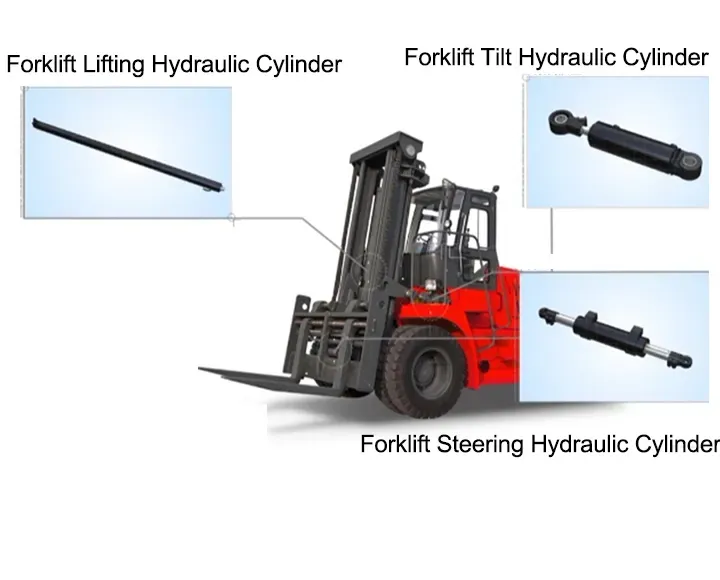

Forklift Steering Hydraulic Cylinder

Forklift Steering Hydraulic Cylinder Parts:

|

1

|

Hex Bolt

|

9

|

Dust Wiper

|

|

2

|

Clevis

|

10

|

Rod Seal

|

|

3

|

Spring Washers

|

11

|

Du Bush

|

|

4

|

Hex Nut

|

12

|

Cylinder Housing assy

|

|

5

|

Guide Bush

|

13

|

Hole Seal

|

|

6

|

O-Ring

|

14

|

Piston

|

|

7

|

O-Ring

|

15

|

O-Ring

|

|

8

|

Round Wire

|

16

|

Piston Rod

|

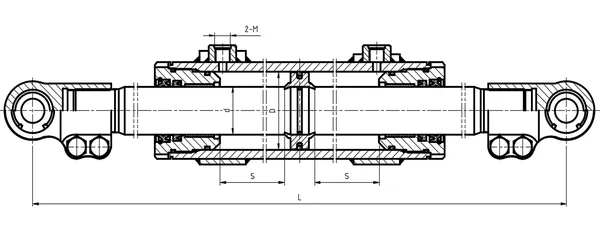

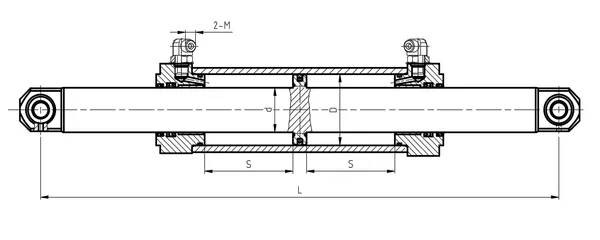

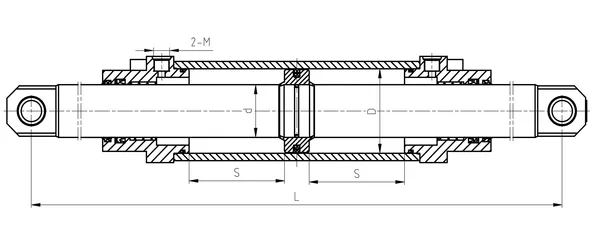

Forklift Steering Hydraulic Cylinder Dimensions:

|

|

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| Steering cylinder | R960-224000-001 | Φ65 | Φ40 | 2*98 | 672 | 10.5MPa | 2-G1/4 | 15kg |

|

|

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| Steering cylinder | A2A300-223000-000 | Φ80 | Φ50 | 2*103 | 652.2 | 10MPa | 2-M16*1.5 | 18kg |

|

|

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| Steering cylinder | XF250-223000-500T | Φ80 | Φ50 | 2*94 | 654 | 16MPa | 2-M16*1.5 | 20kg |

Hydraulic Cylinder Available Brand & Models:

| KOMATSU (PC) | PC30,PC40,PC50,PC56,PC60,PC78,PC100,PC110,PC120,PC130,PC160,PC200-3/5/6/7/8/8MO,PC210,PC220-5/6/7/8/8MO,PC240,PC300/350/360-5/6/7/8/8MO,PC400/450-5/6/7/8/8MO,PC800,PC850 |

| CATERPILLAR (E) | E301.5,E302,E305.5,E306,E307V1/V2/B/C/D/E/F,E308B/C,E120B,E312V1/V2/B/C/D,E313D2,E312D2,E315D, E200B,E320V1/V2/A/B/C/D,E324D,E325C/D,E329D,E330/336C/D,E345C,E349D,E365C,E374,E390 |

| KOBELCO (SK) | SK60-3/5/8,SK75-8/SR, SK100 ,SK120-3/5, SK135-8/SR, SK140-8, SK200-3/5/6/6E, SK210-3/5/6/6E, SK230/250-6E,SK250-8,SK260-8,SK350-8/S8,SK460/480-8 |

| HYUNDAI (R) | R55-5/7, R60-5/7, R80, R110,R130, R200-5, R210-5, R215-5/7,R220-5/7/9, R225-5/7/9, R250,R260,R265,R290,R305,R445,R485, R505 |

| HITACHI (EX.ZX) | EX60,EX100-1/2/3,EX120-1/3/5/6,EX200-1/3/5,EX230-5,EX300-1,EX400 ZAX60,ZAX70,ZA120-6,ZAX200/210-1/3/5/5K,ZAX240,ZAX250,ZAX260,ZAX330-3/5/6,ZAX450/470,ZAX650/670,ZAX850/870 |

|

DOOSAN (DH/DX)

|

DH55, DH60, DH80,DH150, DH215-5/7,DH220-5,DH225-5/7,DH258,DH300-5/7, DH370,DH420,DH500

DX55,DX60,DX75,DX130,DX225-9,DX300,DX380,DX420,DX500 |

|

VOLVO (EC)

|

EC55 ,EC60,EC75,EC80,EC140 ,EC210B/D,EC220D,EC240 ,EC250,EC290,EC300, EC360 EC380,EC460,EC480,EC700,EC750,EC950

|

|

KATO (HD)

|

HD307/308,HD450,HD512,HD700-5/7,HD820-1/2/3/5/R,HD1023-1/3,HD1430-1/3

|

|

OTHER BRAND

|

XCMG,LIUGONG,KUBOTA,CASE,YANMAR,SUNWARD,ZOOMLION,LISHIDE,LIEHERR

|

Application of Forklift Steering Hydraulic Cylinder

Precise Steering Control

The forklift steering hydraulic cylinder plays a crucial role in providing precise control over the forklift’s steering mechanism. By using hydraulic pressure, it ensures smooth and accurate turning of the forklift, allowing operators to navigate through tight spaces and narrow aisles with ease. This precision is essential in environments where forklifts need to maneuver quickly and safely, such as in crowded warehouses, distribution centers, or loading docks.

Increased Maneuverability

One of the key advantages of the forklift steering hydraulic cylinder is its ability to enhance maneuverability. By converting hydraulic power into steering motion, it allows the forklift to make sharp turns with minimal effort from the operator. This is particularly beneficial in environments where forklifts need to change directions frequently or operate in areas with limited space. The ease of steering reduces operator fatigue and improves overall efficiency, allowing forklifts to work in confined or congested areas without sacrificing speed or accuracy.

Enhanced Stability and Safety

Forklifts equipped with a hydraulic steering system benefit from improved stability during operation. The hydraulic steering cylinder helps maintain proper alignment and control, preventing unexpected shifts in direction that could lead to loss of load stability or even tipping. The controlled steering movement allows for smoother transitions between turns, reducing the risk of accidents. This enhanced stability is crucial when operating at high speeds or when transporting heavy loads, as it helps ensure that the forklift remains balanced and safe.

Durability in Harsh Conditions

The forklift steering hydraulic cylinder is designed to withstand the demands of heavy-duty operations. Made from durable materials and engineered to handle high-pressure conditions, the cylinder is capable of enduring constant wear and tear in tough environments. It is built to operate in various weather conditions and environments, including extreme temperatures, moisture, and exposure to dirt or chemicals. This durability ensures that the forklift can continue to perform reliably over extended periods of use, with minimal risk of failure or maintenance issues.

Low Maintenance and Long Lifespan

Thanks to its sturdy construction and efficient design, the forklift steering hydraulic cylinder requires minimal maintenance and provides a long operational lifespan. The system is designed to be self-contained, reducing the risk of external damage or contamination. Regular checks for fluid levels and seals are typically sufficient to maintain optimal performance. With proper maintenance, the hydraulic steering cylinder can deliver consistent and reliable performance throughout the lifespan of the forklift, helping to reduce downtime and lower the overall cost of ownership.

About FMP

FMP is a specialized manufacturer of hydraulic cylinders, with a strong focus on research and production. Since its founding, the company has consistently concentrated on the development of hydraulic cylinders, evolving from producing a variety of products, such as harvesting and construction machinery, to specializing in agricultural tractor components. With over a decade of manufacturing expertise, management experience, and advanced production technology, FMP guarantees the highest quality in its products.

As the company has grown professionally, it has established a comprehensive machining production line, assembly line, and coating line. FMP is supported by a dedicated team of experienced management personnel, skilled mechanical designers, and highly trained technical workers. This ensures stable product quality, while efficiently controlling process continuity and overall production effectiveness.

FMP adheres to the core values of “Technological innovation driving progress, quality creating brands, craftsmanship ensuring quality, and building long-term win-win relationships.” The company remains committed to providing high-quality products while delivering superior customer service, always striving to meet the evolving needs of the market.

|

|

Author: CX