Forklift Lifting Hydraulic Cylinder

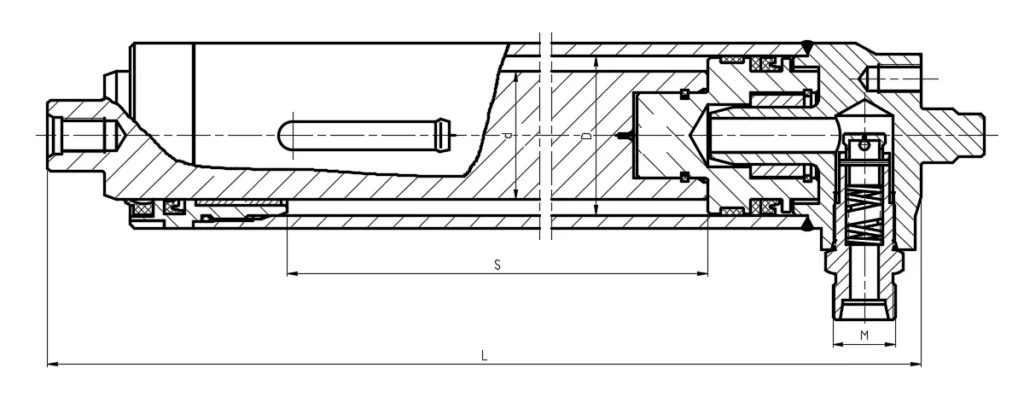

Forklift Lifting Hydraulic Cylinder Dimensions:

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| Lifting cylinder | N30M300-5/400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | G1/2 | 32.6kg |

| Lifting cylinder | A2A30M300-400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | M22*1.5 | 36kg |

| Lifting cylinder | 3.5N4.5H-400000-003 | Φ60 | Φ45 | 1505 | 1780 | 17.5MPa | M22*1.5 | 41kg |

| Lifting cylinder | N35M300-5/400000-001A | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | G1/2 | 46kg |

| Lifting cylinder | A2A35M300-400000-000 | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | M22*1.5 | 50kg |

Features of Forklift Lifting Hydraulic Cylinder

High Lifting Capacity

The forklift lifting hydraulic cylinder is designed to handle heavy loads, providing the necessary force to lift substantial weights. With its robust construction and high-pressure hydraulic system, it ensures smooth and efficient lifting of goods, pallets, and equipment. The cylinder’s strength is vital for forklifts operating in warehouses, distribution centers, and manufacturing plants, where the lifting capacity is essential to handling large and bulky items safely and efficiently.

Durability and Reliability

Forklift lifting hydraulic cylinders are built to endure harsh working conditions, including heavy-duty cycles and extreme environmental factors. Made from high-quality materials, they are resistant to wear, corrosion, and damage caused by frequent use. The cylinder’s reliable performance ensures the forklift operates with minimal downtime, which is crucial for maintaining productivity in fast-paced environments. Routine maintenance and inspection ensure that these cylinders continue to perform at optimal levels, enhancing the longevity of the equipment.

Smooth and Precise Operation

The forklift lifting hydraulic cylinder provides smooth and precise lifting and lowering operations. The hydraulic system allows for controlled, gradual movement, reducing the risk of jerky motions or sudden shifts that could damage the load or compromise safety. This precise control improves operator confidence and efficiency, as they can lift and position loads with accuracy, even in confined or high-stakes situations. The result is a safer, more effective lifting operation that enhances overall forklift performance.

About FMP

FMP is a specialized manufacturer of hydraulic cylinders, with a strong focus on research and production. Since its founding, the company has consistently concentrated on the development of hydraulic cylinders, evolving from producing a variety of products, such as harvesting and construction machinery, to specializing in agricultural tractor components. With over a decade of manufacturing expertise, management experience, and advanced production technology, FMP guarantees the highest quality in its products.

As the company has grown professionally, it has established a comprehensive machining production line, assembly line, and coating line. FMP is supported by a dedicated team of experienced management personnel, skilled mechanical designers, and highly trained technical workers. This ensures stable product quality, while efficiently controlling process continuity and overall production effectiveness.

FMP adheres to the core values of “Technological innovation driving progress, quality creating brands, craftsmanship ensuring quality, and building long-term win-win relationships.” The company remains committed to providing high-quality products while delivering superior customer service, always striving to meet the evolving needs of the market.

|

|

Author: CX