|

|

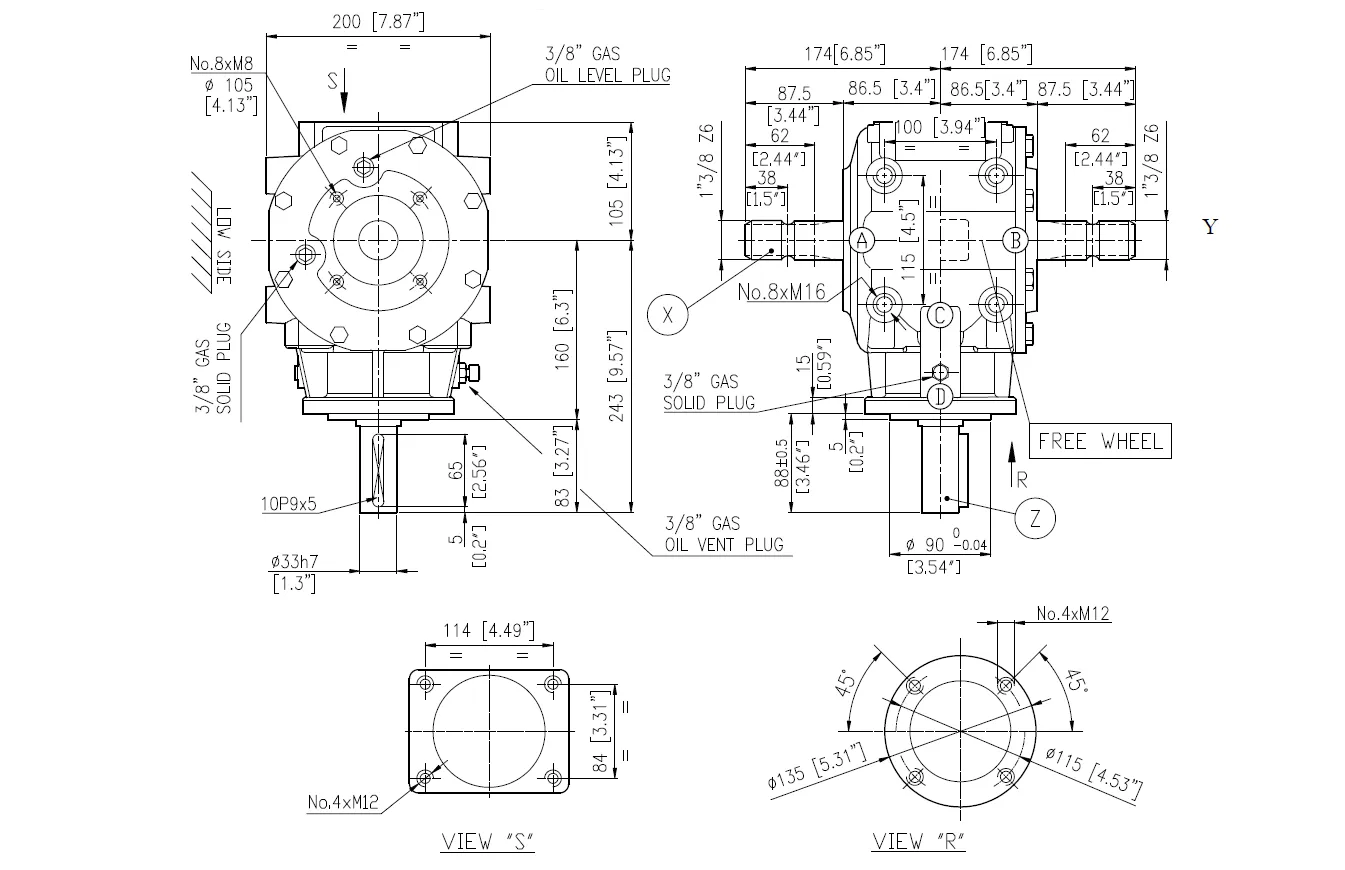

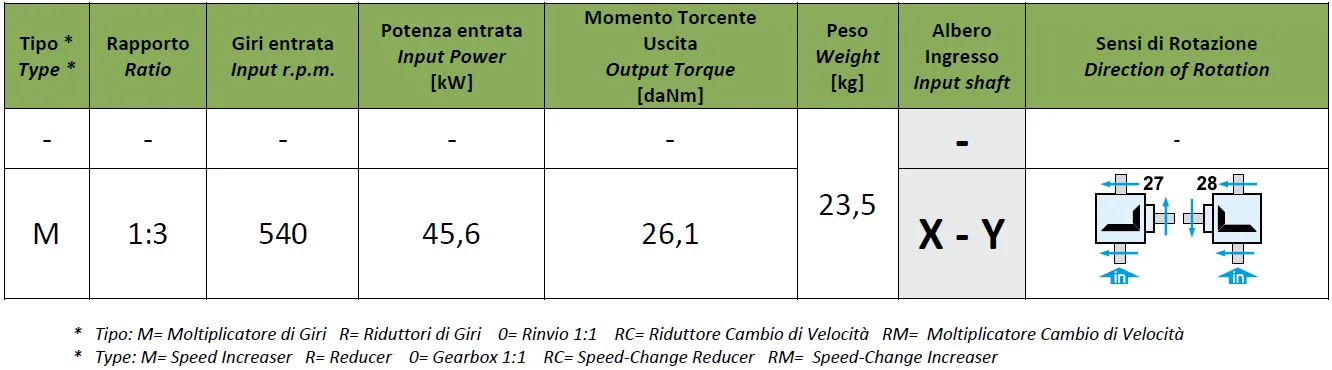

Specifications of Flail Mower Gearbox T-313J (1:3)

| Description |

Flail Mower Gearboxes – Replacement of Comer Gearbox T-313J 1:3

|

|---|---|

| Application |

Mowers

|

| Consists of |

|

| Technical information |

|

| Contains oil |

No

|

| Max. oil capacity |

1.5 l

|

| Oil SAE viscosity grade |

80W-90

|

| Weight |

27 kg

|

| Gear arrangement Increasing |

21-22

|

| Input power kW / HP Increasing |

45.6 / 62 kW/HP

|

| Input shaft Increasing |

X

|

| Output Torque DaNm Increasing |

26.1 daNm

|

| Ratio Increasing |

1 : 3

|

| Ratio Reducing |

3: 1

|

| Shaft X |

1.3/8 (A)

|

| Shaft Z |

33h7 (B)

|

Characteristics of Flail Mower Gearbox T-313J (1:3)

The Flail Mower Gearbox T-313J with a 1:3 gear ratio is designed to provide excellent cutting power and reliability for a variety of agricultural and landscaping applications. Below are the key characteristics of this gearbox:

High Torque Output

The 1:3 gear ratio of the T-313J gearbox provides a high torque output, making it ideal for tackling tougher vegetation and more challenging mowing conditions. This gear ratio ensures that the mower blades receive sufficient power to cut through thicker grass, weeds, and light brush, ensuring a clean and efficient cut even in demanding environments. The higher torque allows the mower to perform better on uneven or rough terrains.

Durable and Heavy-Duty Construction

The T-313J gearbox is built with high-quality materials, ensuring a long service life and reliable operation in agricultural environments. The gearbox features reinforced gears, durable bearings, and a robust housing to withstand the stress of continuous use, especially in conditions where the mower is subjected to heavy workloads. Its rugged construction makes it suitable for intensive tasks without compromising performance.

Enhanced Power Transmission Efficiency

The gearbox is engineered for optimal power transmission efficiency. The 1:3 gear ratio helps maintain smooth operation while transferring power from the tractor’s PTO system to the mower blades. The design of the gearbox minimizes energy loss, ensuring that more of the tractor’s power is used efficiently for cutting. This reduces fuel consumption and increases operational efficiency.

Versatility in Applications

With its high torque and durability, the T-313J gearbox is suitable for a wide range of applications, including mowing grass, weeds, and light brush in agricultural fields, parks, roadsides, and landscaping projects. Its performance makes it ideal for tasks that require more power for cutting thicker or more dense vegetation. Whether used in larger fields or uneven terrain, the T-313J gearbox provides the necessary power for consistent and efficient mowing.

Low Maintenance and Long Service Life

The T-313J gearbox is designed for low maintenance and long-lasting performance. It comes equipped with sealed bearings to reduce the ingress of dirt and moisture, minimizing wear and tear. Regular lubrication and periodic inspections are sufficient to keep the gearbox in optimal condition. Its durability and reduced maintenance needs make it a cost-effective solution for long-term use.

The Flail Mower Gearbox T-313J (1:3) is a powerful, durable, and efficient gearbox, ideal for heavy-duty agricultural and landscaping tasks. With its high torque output, robust construction, and smooth power transmission, it delivers excellent performance in demanding mowing applications. The T-313J gearbox is a reliable choice for those who require a durable and efficient gearbox for their flail mowers, offering low maintenance needs and long-term operational efficiency.

|

|

Common Uses of Flail Mower Gearboxes

Flail mower gearboxes are essential components in a wide variety of agricultural, landscaping, and industrial applications. These gearboxes are designed to provide efficient power transfer from the tractor’s PTO (Power Take-Off) system to the mower blades, enabling effective cutting and shredding of vegetation. Here are the common uses of flail mower gearboxes:

Agricultural Fields and Farms

Flail mowers equipped with powerful gearboxes are widely used in agricultural fields for mowing grass, weeds, and other vegetation. They are particularly useful for maintaining fields that grow crops such as corn, wheat, and soybeans, as well as in pasture land for livestock. The robust power and versatility of flail mower gearboxes make them ideal for clearing overgrown fields or mowing between rows in crop fields, helping improve field conditions and promoting healthy crop growth.

Roadside and Highway Maintenance

Flail mower gearboxes are commonly used in roadside vegetation management, especially in areas with rough terrain or dense undergrowth. These mowers are equipped with high-torque gearboxes, making them capable of mowing through thick grass, bushes, and even small trees along highways, rural roads, and urban streets. The gearboxes allow operators to maintain clean and safe roadways by clearing vegetation that might obstruct traffic, signage, or visibility.

Landscaping and Grounds Maintenance

In landscaping applications, flail mower gearboxes are frequently used to maintain parks, golf courses, sports fields, and other public spaces. These mowers are capable of delivering a clean, even cut on large areas of grass and weeds, providing an aesthetically pleasing result. The ability to handle tougher vegetation like bushes or brambles makes them useful for land reclamation or weed management in landscaped areas. The T-290A, for example, is often used in these environments due to its combination of high torque and versatility.

Forestry and Brush Clearing

Flail mowers with strong gearboxes are an excellent tool for forestry applications, especially for brush clearing and managing small trees, shrubs, and dense underbrush in forests or woodlands. The high torque provided by the gearbox allows the flail mower to handle dense, woody vegetation and clear brush effectively, which is essential for forest fire prevention, improving wildlife habitats, or preparing land for timber production.

Municipal and Utility Work

Flail mower gearboxes are also used for municipal maintenance, such as clearing grassy areas, public parks, and industrial sites. They are essential for utility vegetation control, including maintaining clear access to electricity lines, water pipelines, and communication towers. The gearboxes provide the necessary power to mow through vegetation around utilities while ensuring a consistent cutting action. These mowers are also used in landfills and waste management facilities to clear unwanted vegetation in the vicinity.

Flail mower gearboxes are commonly used in a variety of settings where reliable power and efficient cutting are required. Their high torque and durable construction make them ideal for agriculture, roadside maintenance, forestry, landscaping, utility work, and recreational areas. The ability of the gearbox to convert PTO power into the appropriate speed and torque for the mower blades ensures that flail mowers can handle tough, dense vegetation across a range of challenging environments.

|

|

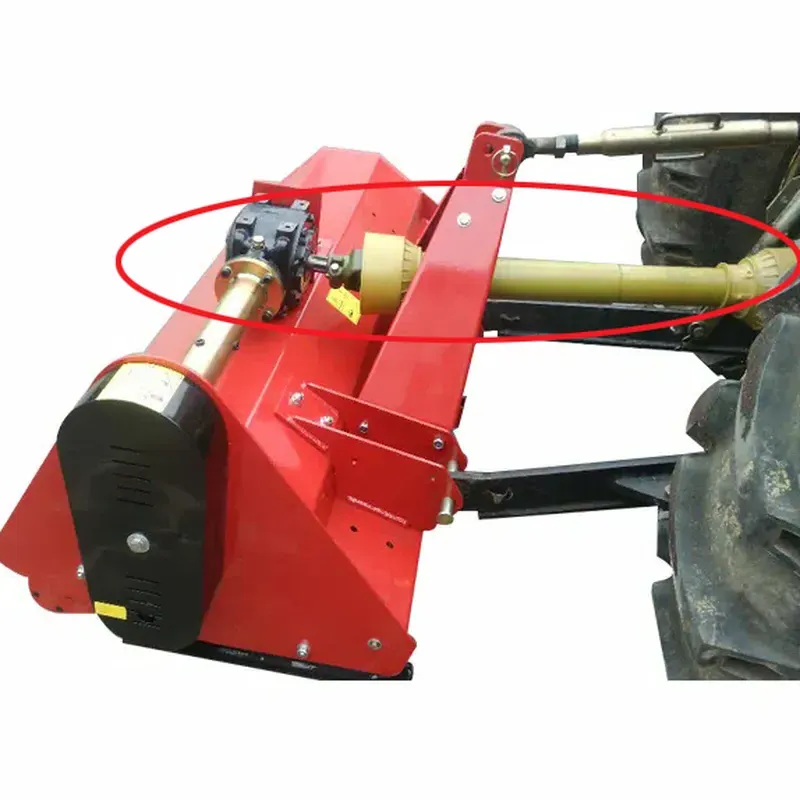

How to Connect a Flail Mower Gearbox to a Flail Mower

Connecting a flail mower gearbox to a flail mower is a critical step to ensure smooth operation, optimal performance, and longevity of the equipment. The gearbox is responsible for converting the rotational power from the tractor’s PTO (Power Take-Off) system into the necessary speed and torque to rotate the mower blades. Here’s a step-by-step guide on how to connect the flail mower gearbox to the mower:

Preparation:

Before starting the installation process, ensure that you have the following tools and equipment ready:

- Wrenches or socket set

- Screwdrivers or impact driver (if needed)

- Lubricating oil or grease (for lubrication during assembly)

- PTO shaft (compatible with your gearbox and tractor)

- Safety gloves and goggles

Additionally, make sure both the flail mower and gearbox are clean and free from debris to ensure proper installation.

Position the Gearbox and Mower:

- Lift or support the flail mower using a suitable lifting device (e.g., hoist or jack), if needed, to provide adequate clearance for easy connection.

- Place the gearbox in position: Align the gearbox with the mounting bracket or frame of the mower where it will be attached. Most flail mower gearboxes have a designated mounting point on the mower frame. The output shaft (which drives the mower blades) should be pointing towards the blades.

Align the Input and Output Shafts:

- Align the input shaft of the gearbox (where the PTO shaft will connect) with the corresponding PTO input on the tractor or implement.

- Align the output shaft (where the mower blades are driven) with the shaft or pulley system on the flail mower that transmits power to the mower blades.

- Ensure that both shafts are aligned straight and parallel to avoid undue stress on the gearbox or PTO shaft during operation.

Secure the Gearbox to the Mower:

- Mount the gearbox: Most flail mower gearboxes are bolted onto the mower frame. Use the provided bolts, nuts, and washers to securely attach the gearbox to the frame. Tighten the bolts using a wrench or impact driver to ensure a tight connection.

- Check alignment again after securing the gearbox to ensure no misalignment occurs during tightening.

Connect the PTO Shaft:

- Attach the PTO shaft to the gearbox input: The PTO shaft will typically have two ends—one for the tractor and one for the gearbox. Slide the PTO shaft over the input shaft of the gearbox and secure it in place using the appropriate clamp or pin.

- Connect the other end of the PTO shaft to the tractor’s PTO output shaft.

- Ensure that the PTO shaft is the correct length to avoid overextension or misalignment. If the shaft is adjustable, ensure it is correctly set for the right length.

By following these steps, you can successfully connect the flail mower gearbox to the mower, ensuring that the machine operates efficiently and safely. Proper alignment, secure connections, and lubrication are crucial to maintaining the longevity of the gearbox and ensuring optimal mowing performance.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX