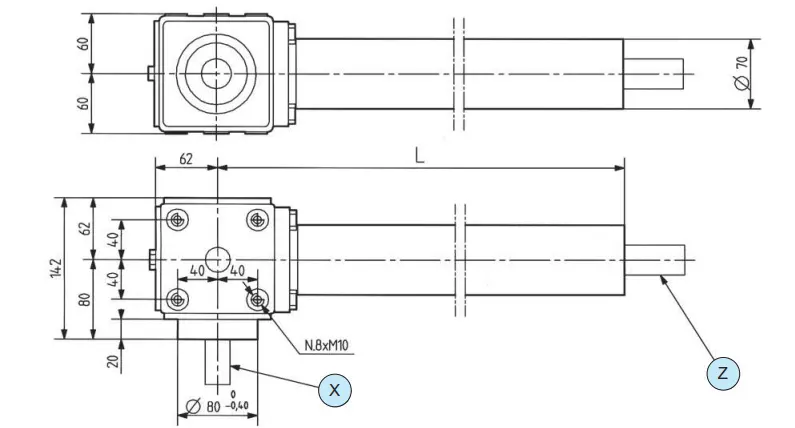

Flail Mower Gearbox LL-5L Specification

| i | 1.9 |

| N1[rpm] | 540 |

| P1[kW] | 11 |

| M2[Nm] | 99 |

Shaft X |

1” 3/8 Z6 |

Shaft Z |

L60 Φ25 |

| Input | X |

Flail Mower Gearbox Features

The Flail Mower Gearbox is an essential component that enables the efficient operation of flail mowers, providing the necessary power transmission to drive the mower blades. Designed for durability, reliability, and high performance, the gearbox ensures optimal cutting efficiency while withstanding the harsh conditions of agricultural and land maintenance applications. Below are the key features of a Flail Mower Gearbox:

High Power Transmission Efficiency

Flail mower gearboxes are designed to provide efficient power transmission from the tractor’s PTO (Power Take-Off) system to the flail mower blades. The gearbox effectively transfers torque, enabling the mower to cut through dense grass, brush, and other vegetation. The design is optimized to ensure that power is delivered efficiently, minimizing energy losses and maximizing operational performance.

Durable and Robust Construction

Flail mower gearboxes are built with high-strength materials to withstand the heavy loads and high torque encountered during operation. Components such as gears, shafts, and housings are engineered for high durability, making the gearbox capable of handling tough mowing conditions, including thick vegetation, stony soil, and rough terrain. The rugged construction ensures that the gearbox can perform reliably for extended periods with minimal maintenance.

Precision Gear Ratio

The gear ratio of the flail mower gearbox is crucial for achieving the correct balance between blade speed and cutting efficiency. A typical gearbox may feature a ratio of 1:1.5 to 1:2, depending on the specific model and application. The precision gear ratio ensures that the blades rotate at an optimal speed for cutting, allowing for clean and uniform cuts while preventing excessive wear on the mower blades and gearbox.

Compact and Lightweight Design

Despite its powerful capabilities, the flail mower gearbox is designed to be compact and lightweight, facilitating easy installation and integration with the mower. Its small size and reduced weight ensure that it does not add unnecessary bulk to the mower, making it easier to maneuver and reducing the load on the tractor. The lightweight design also improves the overall efficiency of the mower by reducing energy consumption.

Overload Protection

Flail mower gearboxes are often equipped with overload protection mechanisms, such as shear pins, torque limiters, or overload clutches. These safety features prevent damage to the gearbox and mower components in the event of sudden obstructions, like rocks or heavy debris. If an obstruction occurs, the overload protection disengages the transmission, preventing further damage and allowing for quick repairs. This feature improves safety and extends the operational life of the gearbox.

The Flail Mower Gearbox is a highly engineered component that provides essential power transmission for flail mowers, ensuring smooth, efficient, and reliable operation. Its key features, including durable construction, precision gear ratios, overload protection, and low-maintenance design, make it an essential part of any flail mower system. Whether used for cutting grass, brush, or heavier vegetation, the flail mower gearbox plays a critical role in optimizing performance and extending the life of the equipment.

Agricultural PTO Shaft for Flail Mower Gearbox

The Agricultural PTO Shaft for Flail Mower Gearbox is a critical component that ensures the efficient transfer of power from the tractor’s PTO (Power Take-Off) system to the flail mower gearbox. This shaft is designed to handle high torque and deliver smooth, consistent power to the mower blades, allowing for optimal cutting performance in demanding agricultural applications. Below are the key features and benefits of the Agricultural PTO Shaft for Flail Mower Gearbox:

Efficient Power Transmission

The primary function of the PTO shaft is to transmit power from the tractor to the flail mower gearbox. By linking the tractor’s PTO system to the mower’s gearbox, the PTO shaft enables the gearbox to turn the mower blades at the required speed for efficient cutting. This power transmission is essential for ensuring that the mower operates at its peak performance, delivering consistent results when mowing grass, brush, or other vegetation.

Durable Construction

The PTO shaft for flail mower gearboxes is built for high strength and durability. Constructed from high-quality, wear-resistant materials, the shaft is designed to withstand the extreme conditions of agricultural operations. The shaft is capable of handling high levels of torque, shock loads, and vibrations without compromising its performance. This robust construction ensures a long service life and reduces the need for frequent replacements or repairs.

Safety Features

Safety is a key consideration in the design of the PTO shaft for flail mower gearboxes. The shaft is equipped with safety shields to prevent accidental contact with rotating parts. These shields protect the operator and others nearby from potential injuries. Additionally, overload protection mechanisms, such as shear bolts or torque limiters, are often included to prevent damage to the gearbox or tractor in the event of an obstruction or excessive load. This ensures that the PTO shaft and its components are safe to use under challenging conditions.

Ease of Installation and Adjustment

The Agricultural PTO Shaft is designed for easy installation and adjustment. The shaft typically features a telescoping design, allowing it to be adjusted to the correct length to fit different tractor and mower configurations. This adjustability ensures that the PTO shaft can accommodate various machine models, improving versatility across different agricultural operations. The PTO shaft is equipped with quick-connect couplings, making it easy to attach and detach from both the tractor and the flail mower gearbox, saving time and effort during setup.

Low Maintenance Requirements

The PTO Shaft for Flail Mower Gearbox is designed to require minimal maintenance. It is equipped with sealed bearings and lubricated components to reduce friction and wear, ensuring smooth operation and extending the shaft’s lifespan. Routine maintenance typically involves inspecting the shaft for damage or wear, checking the lubrication, and ensuring that all safety shields and components are properly in place. These low maintenance requirements make the PTO shaft a convenient and reliable choice for regular use.

The Agricultural PTO Shaft for Flail Mower Gearbox is an essential component for powering flail mowers in agricultural operations. With its durable construction, safety features, and ease of installation, it ensures efficient power transmission while enhancing the performance and longevity of the mower. Its low maintenance requirements, corrosion resistance, and versatility make it a reliable choice for a wide range of agricultural applications. By providing consistent power and ensuring smooth operation, the PTO shaft plays a vital role in optimizing the effectiveness of flail mowers, whether used for routine lawn care, heavy-duty brush clearing, or land maintenance.

About FMP

Headquartered in Italy, FMP is a leading manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, primarily for the agricultural machinery sector. Renowned for our precision engineering, innovation, and unwavering reliability, FMP has established itself as a trusted partner in meeting the evolving demands of both the agricultural and industrial markets. Our comprehensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other critical components, all designed to provide effective, customized solutions across a wide range of applications.

At FMP, we understand that every client has unique needs and challenges. This is why we specialize in offering tailored solutions, whether through individual components or fully integrated systems. We take a collaborative approach, working closely with our customers to ensure that each solution is not only effective but also efficient. Our commitment to fast, professional responses and expert guidance guarantees that every inquiry is handled with the utmost care and precision, ensuring the best outcomes for our clients.

We place a strong emphasis on open and ongoing communication, particularly in the development of new products. Our dedicated team works directly with clients to fully understand their requirements, offering valuable insights and recommendations that lead to optimal solutions. Whether we are designing innovative products or fulfilling existing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time, ensuring that our clients receive the best service and results.

At the core of FMP’s operations is our relentless focus on quality. We adhere to the highest manufacturing standards, employing stringent quality control measures to ensure that every product not only meets but exceeds industry expectations. This commitment to quality, coupled with our core values of integrity, teamwork, and perseverance, has allowed us to build lasting, trusting relationships with customers in nearly 30 countries around the world.

FMP is always eager to build global partnerships and remains dedicated to providing expert guidance and custom solutions to meet the diverse needs of our clients. Our approach goes beyond merely delivering products; we aim to cultivate long-term relationships that contribute to the success of every project. Whether you require innovative solutions for a new venture or ongoing support for an existing system, FMP is here to address your technical challenges and help ensure your sustained success.

Author: CX