Specifications of Flail Mower Gearbox L-5A (1:1.89)

| Product Description |

Flail Mower Gearboxes – Replacement of Comer Gearbox L-5A 1:1.89

|

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

| Max. output torque |

22.8 daNm

|

| Contains oil |

No

|

| Max. oil capacity |

0.4 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG20

|

| Weight |

7.7 kg

|

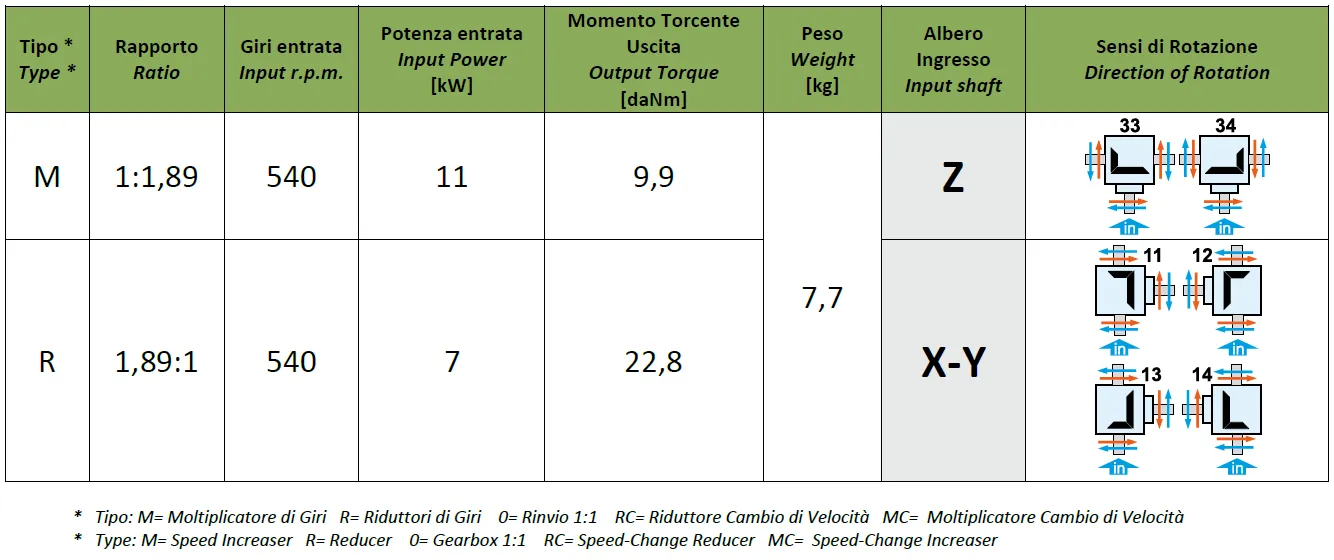

| Gear arrangement Increasing |

13 – 14

|

| Gear arrangement Reducing |

1 – 2

|

| Input power kW / HP Increasing |

11 / 15 kW/HP

|

| Input shaft Increasing |

X

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

7 / 9.5 kW/HP

|

| Output Torque DaNm Increasing |

9.9 daNm

|

| Ratio Increasing |

1: 1.89

|

| Ratio Reducing |

1.89: 1

|

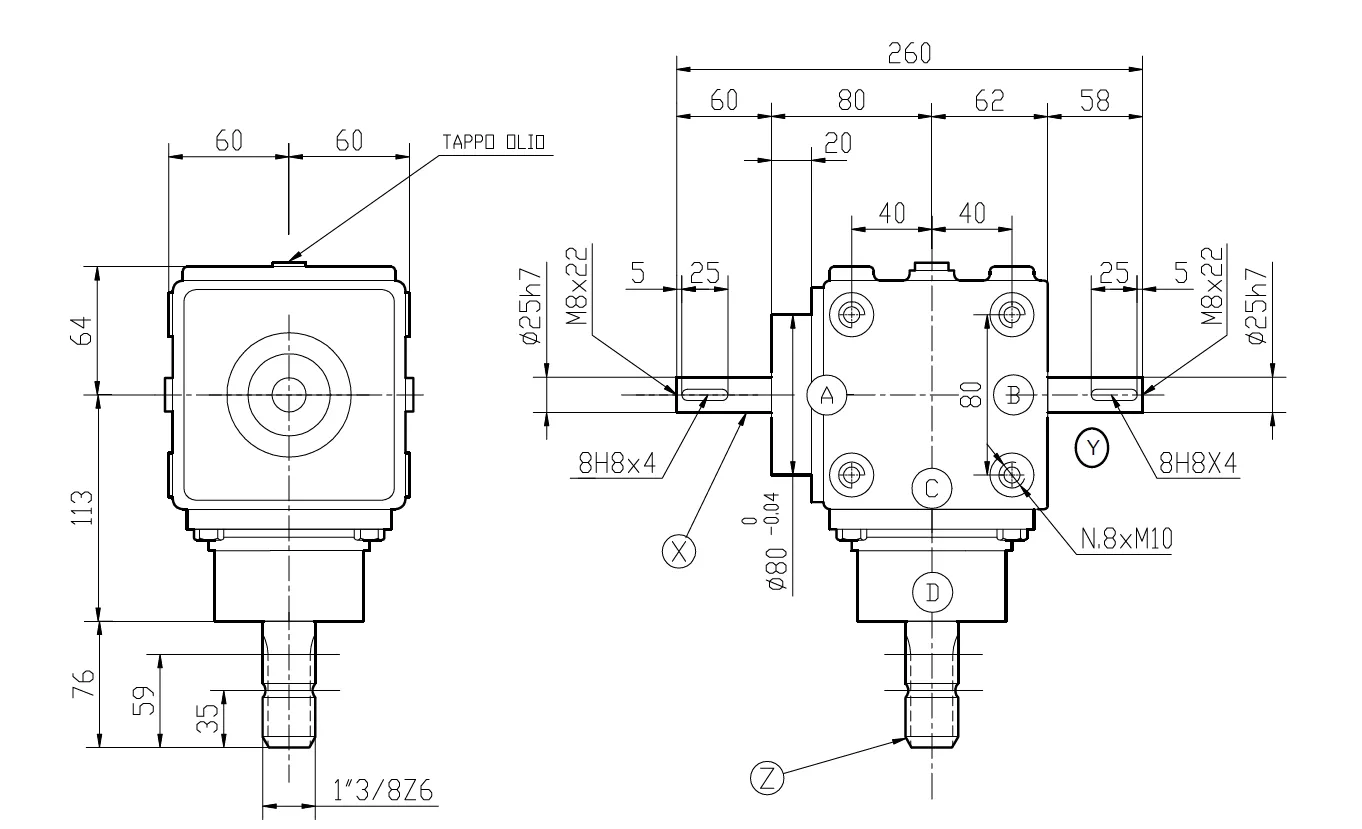

| Shaft X |

25 (M)

|

| Shaft Z |

25 (D)

|

Benefits of Flail Mower Gearbox L-5A (1:1.89)

The Flail Mower Gearbox L-5A (1:1.89) is designed to provide efficient power transmission for flail mowers, ensuring smooth and reliable performance in various agricultural and industrial mowing applications. With its optimized gear ratio of 1:1.89, the gearbox offers several advantages that contribute to improved productivity, reduced maintenance, and longer operational life. Below are the key benefits of the L-5A Flail Mower Gearbox:

Efficient Power Transmission

The L-5A gearbox is designed with a 1:1.89 gear ratio, providing efficient power transfer from the PTO (Power Take-Off) shaft to the mower blades. This high-efficiency design allows the gearbox to transmit power effectively, ensuring that the mower blades operate at optimal speeds for cutting grass, brush, and other vegetation. The gearbox helps maximize the mower’s performance, providing consistent cutting results and reducing energy consumption.

Enhanced Durability and Reliability

Constructed with high-quality materials and precision engineering, the L-5A gearbox is built to withstand the demanding conditions of flail mowing. It offers high durability and reliability, ensuring that it can handle the high torque and stress associated with heavy-duty mowing tasks. Whether used in agricultural, landscaping, or industrial applications, the gearbox is designed to perform under tough conditions, reducing the risk of breakdowns and extending the operational life of the flail mower.

Smooth Operation with Reduced Vibration

The L-5A gearbox is engineered for smooth operation, which helps minimize vibrations during mowing. This is important not only for maintaining the quality of the cut but also for improving operator comfort and reducing wear on the mower. The smooth operation also reduces the overall noise levels, making it more pleasant for operators to use the equipment for extended periods without fatigue.

Low Maintenance and Cost-Effectiveness

The L-5A gearbox is designed for low maintenance, thanks to its robust construction and high-quality seals that protect internal components from dirt, debris, and moisture. This reduces the frequency of maintenance checks and ensures longer intervals between oil changes or other maintenance activities. With fewer maintenance requirements, the gearbox helps lower the overall cost of ownership, providing a more cost-effective solution for users in both short-term and long-term operations.

Versatility for Various Mowing Applications

The L-5A (1:1.89) gearbox is a versatile component suitable for use in a wide range of flail mower applications, including grass cutting, brush clearing, and land reclamation. Its compatibility with different mower models and its ability to handle varying mowing conditions make it an excellent choice for users who require reliable performance in diverse environments. The gearbox can be used effectively in agricultural fields, roadsides, parks, and other vegetation management tasks, offering flexibility for different operational needs.

The Flail Mower Gearbox L-5A (1:1.89) provides significant benefits in terms of efficient power transmission, enhanced durability, and low maintenance. Its robust design ensures reliable performance in demanding mowing applications, while its smooth operation helps improve both the quality of the cut and operator comfort. With a versatile range of applications and cost-effectiveness, the L-5A gearbox is an excellent choice for anyone looking to improve the performance and longevity of their flail mower.

|

|

Installation of Flail Mower Gearboxes: Precautions

Installing a Flail Mower Gearbox requires careful attention to detail to ensure optimal performance, safety, and longevity of both the gearbox and the mower. Following the correct installation procedures and taking necessary precautions can prevent damage, improve efficiency, and extend the life of your equipment. Below are some essential precautions to follow during the installation of a flail mower gearbox:

Check Compatibility with the Mower

Before installation, verify that the flail mower gearbox is the correct model for your mower. Ensure the gearbox’s shaft size, coupling, and mounting align with the mower’s specifications. The gearbox ratio (e.g., 1:1.89) should match the recommended power and torque requirements of the mower for optimal cutting performance. Using an incompatible gearbox could result in mechanical failure or poor mower efficiency.

Ensure Proper Alignment

Correct alignment of the gearbox with the PTO shaft is crucial for preventing misalignment-related damage, such as excessive wear, vibration, or power loss. The gearbox input shaft and the PTO output shaft should be properly aligned to ensure smooth and efficient power transmission. Misalignment can cause increased wear on the bearings, seals, and gears, which may shorten the gearbox’s lifespan.

Lubrication and Oil Levels

Before installation, inspect the lubrication levels of the gearbox. Ensure that the gearbox is filled with the correct type and amount of lubricant as specified by the manufacturer. Lubrication is essential for reducing friction and wear inside the gearbox, ensuring smooth operation and preventing overheating. Use only the recommended oil grade to avoid damaging the internal components. Always check the oil level after installation and top up if necessary.

Tighten Bolts and Fasteners Properly

During installation, securely tighten all bolts and fasteners to prevent any looseness that could result in malfunction. Ensure that the gearbox is mounted firmly to the mower frame to avoid vibration and reduce the risk of failure. Use the recommended torque specifications for each fastener to prevent over-tightening or under-tightening, which could lead to damage or operational issues.

Inspect PTO Shaft and Couplings

Inspect the PTO shaft, couplings, and universal joints before installation. Ensure that the PTO shaft is free from wear, cracks, or damage that could compromise power transmission. If the shaft or couplings are worn, replace them before proceeding with the installation. Also, ensure the couplings fit snugly without excessive play or gaps, as improper coupling can lead to vibrations and stress on the gearbox.

Proper installation of a flail mower gearbox is essential to ensure reliable operation and maximize the lifespan of both the gearbox and the mower. By verifying compatibility, ensuring proper alignment, maintaining correct lubrication, and securing all fasteners, you can prevent common installation issues that may lead to mechanical failure. Regular inspection and maintenance are equally important to keep the gearbox running smoothly throughout its service life.