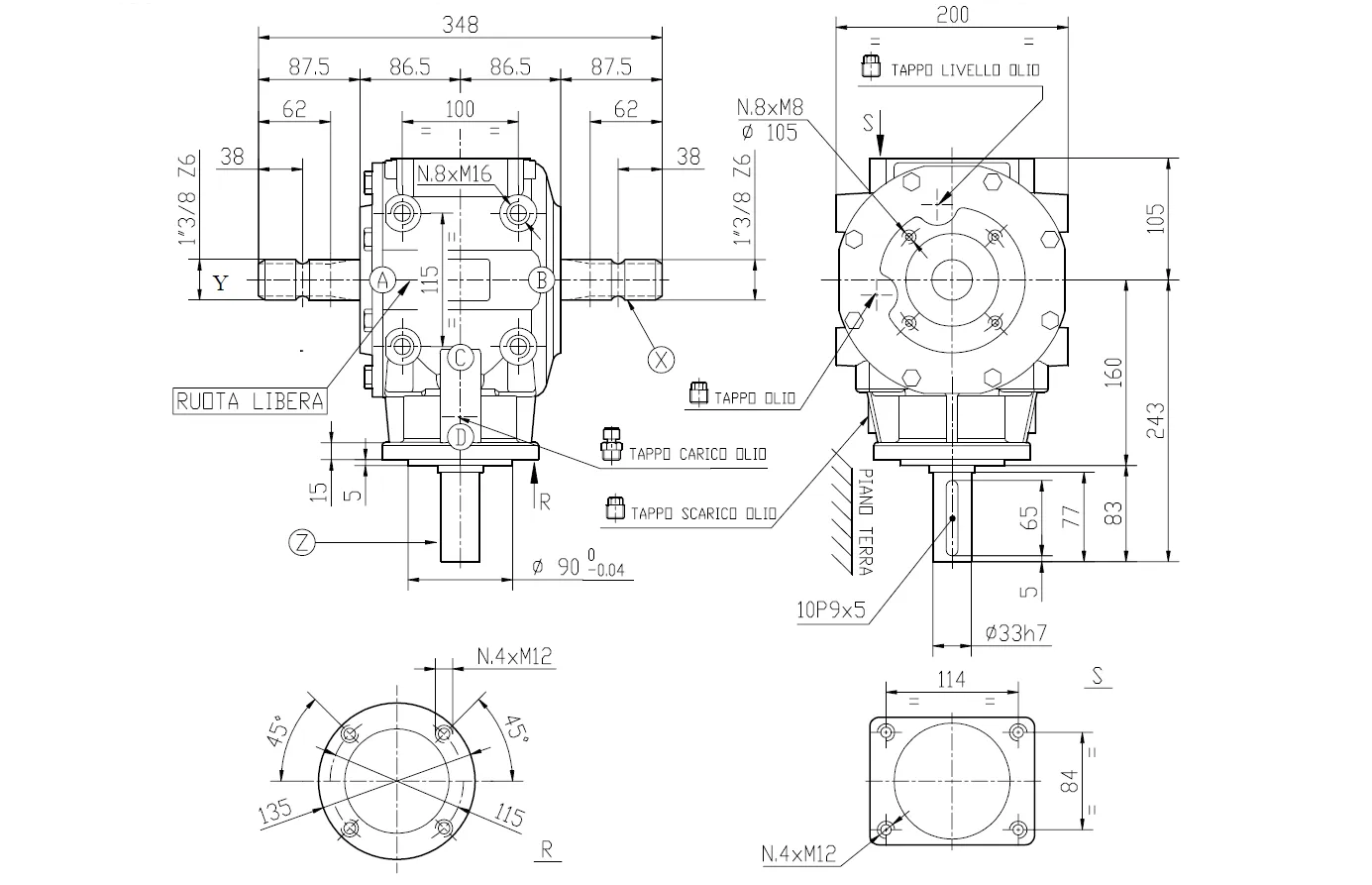

Specifications of Flail Mower Gearbox T-312A (1:1.6)

| Product Description |

Flail Mower Gearbox – Replacement of Comer Gearbox T-312A 1:1.6

|

|---|---|

| Product details |

|

| Application range |

Mowers

|

| Model |

Gearbox T-312A

|

| Max. input rotation speed |

540 r/min

|

| Contains oil |

No

|

| Max. oil capacity |

1.5 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| Weight |

27 kg

|

| Gear arrangement Increasing |

27-28

|

| Input power kW / HP Increasing |

55.9 kW

|

| Input shaft Increasing |

X – Y

|

| Output Torque DaNm Increasing |

59.9 daNm

|

| Ratio Increasing |

1: 1.6

|

| Ratio Reducing |

1.6: 1

|

| Shaft X |

1 3/8″ (6) (A)

|

| Shaft Y |

1 3/8″ (6) (A)

|

| Shaft Z |

33 h7 (B)

|

Features of Flail Mower Gearbox T-312A (1:1.6)

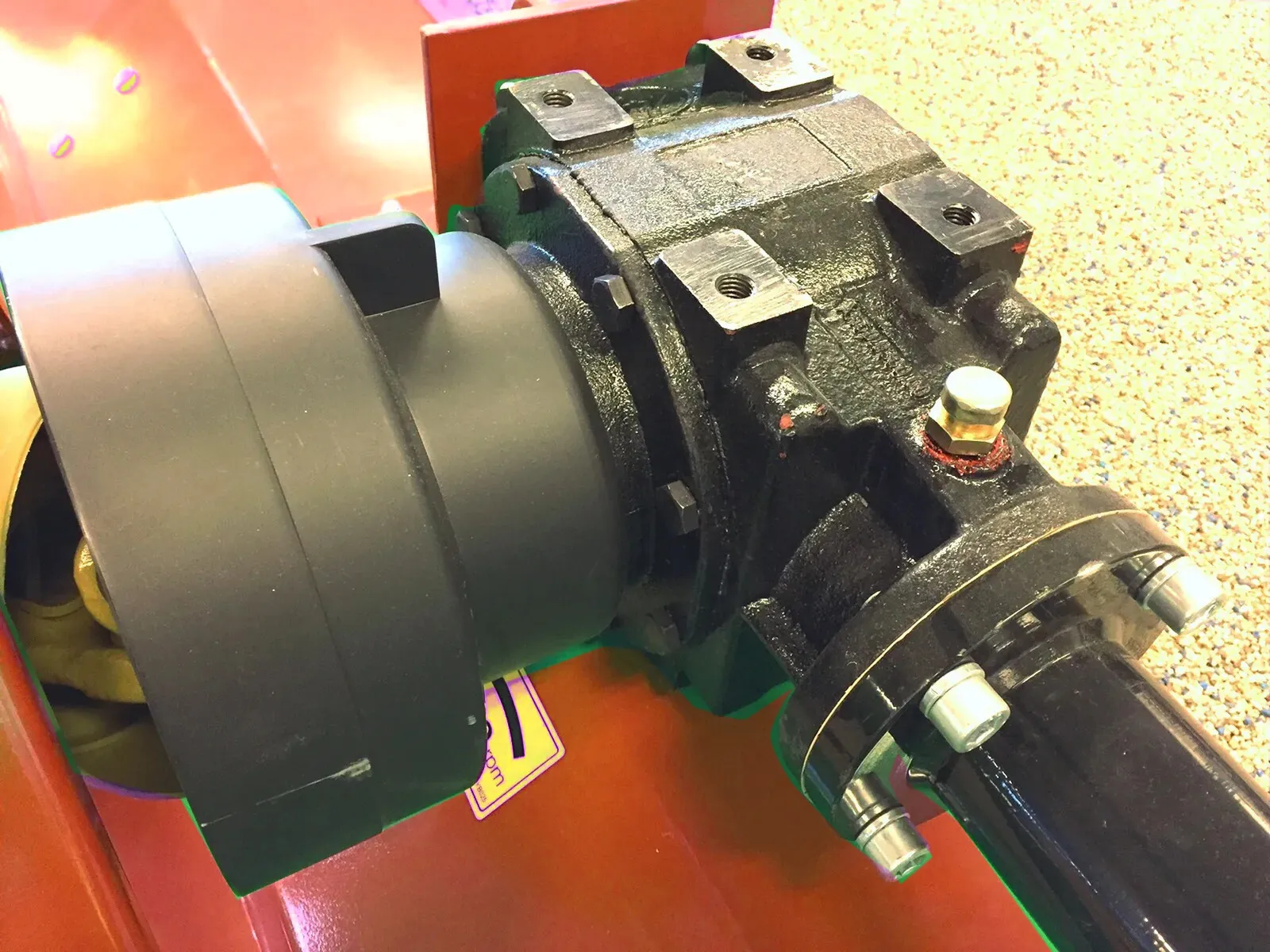

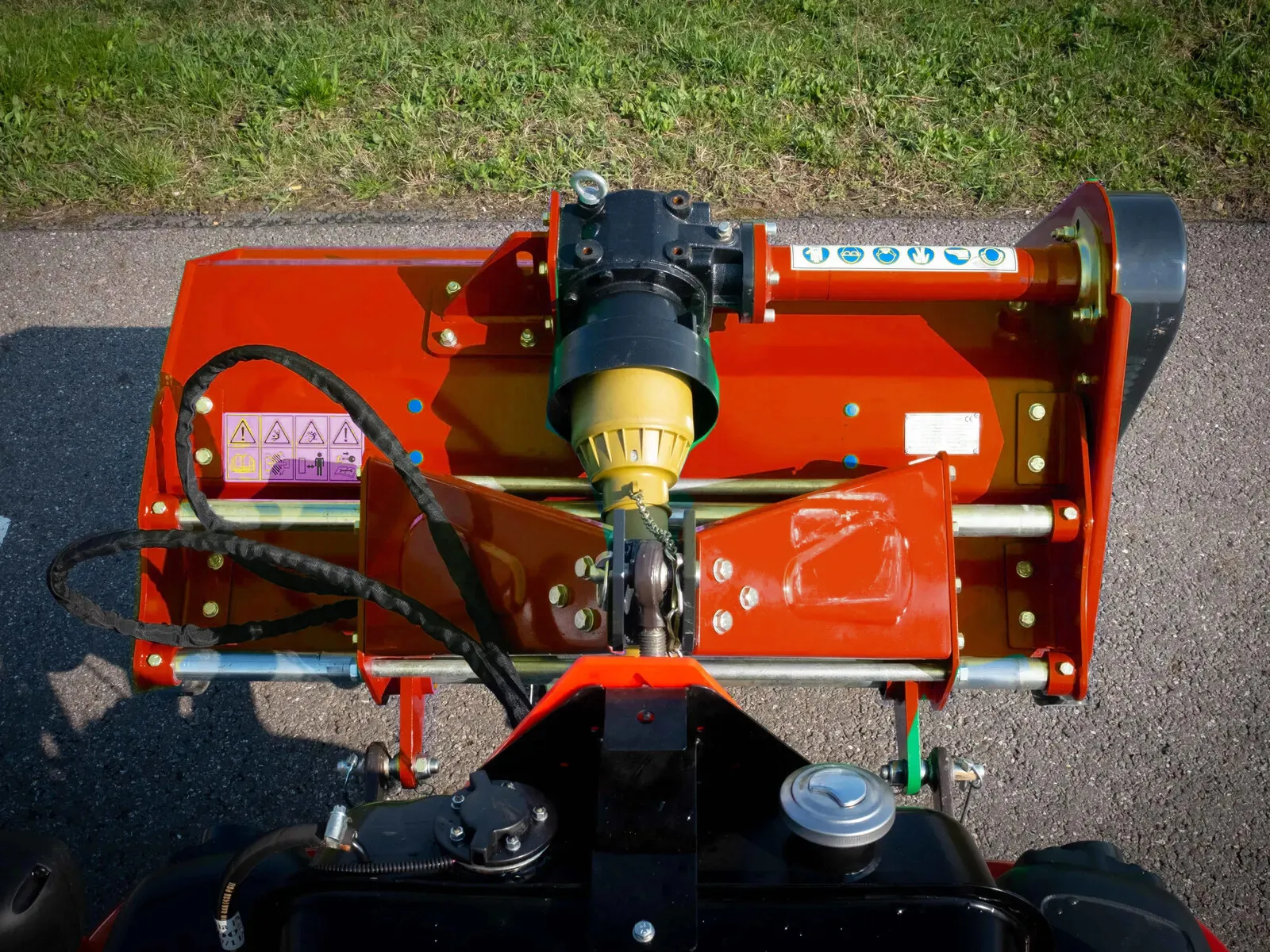

The Flail Mower Gearbox T-312A (1:1.6) is designed for efficient power transmission and high-performance cutting in agricultural and landscaping applications. It provides optimal operation for flail mowers, enabling precise and effective shredding of grass, brush, and other vegetation. Below are the key features of the T-312A Flail Mower Gearbox:

Optimal Gear Ratio (1:1.6)

The gear ratio of 1:1.6 is carefully selected to provide the perfect balance between torque and speed for flail mower applications. This ratio allows the gearbox to deliver sufficient power to the flail blades while maintaining the appropriate rotational speed for efficient cutting. The design ensures that the mower can handle tougher vegetation like thick grass, weeds, and light brush without overloading the system.

Durable and High-Quality Construction

The T-312A gearbox is made from high-strength, wear-resistant materials, ensuring long-lasting performance under heavy-duty conditions. The housing is constructed to withstand the mechanical stresses and impacts that occur during operation, especially when working with dense or rugged terrain. The internal gears are precision-machined to provide smooth power transmission, reducing wear and tear while maintaining high operational efficiency.

Heavy-Duty Bearings

Equipped with heavy-duty bearings, the T-312A gearbox is built to handle high loads and high rotational speeds. These bearings minimize friction and wear, enhancing the longevity and reliability of the gearbox. The use of quality bearings helps in ensuring smoother operation and reducing downtime due to mechanical failure, making the gearbox highly suitable for continuous and demanding applications.

Easy Maintenance and Lubrication

The T-312A flail mower gearbox is designed for easy maintenance. It features user-friendly access points for lubrication and oil changes, allowing operators to quickly perform routine maintenance. Proper lubrication is critical to ensure the gearbox runs smoothly and remains durable over time. The gearbox is equipped with sealed bearings to reduce the need for frequent maintenance while ensuring effective performance in various working conditions.

Versatile and Flexible Application

The T-312A gearbox is versatile and suitable for a range of flail mower models used in agriculture, landscaping, and grounds maintenance. It can be paired with a variety of PTO shafts and is compatible with both light and medium-duty mowers. This gearbox is perfect for mowing large areas of grass, clearing brush, and performing general land maintenance tasks in both commercial and residential settings.

The Flail Mower Gearbox T-312A (1:1.6) is a high-performance and durable gearbox designed for a wide range of agricultural and landscaping applications. With its optimal gear ratio, high-quality construction, and easy maintenance features, it provides efficient power transmission and reliable operation for flail mowers. Whether used for mowing grass, clearing brush, or maintaining larger agricultural fields, the T-312A gearbox ensures smooth, efficient, and long-lasting performance.

|

|

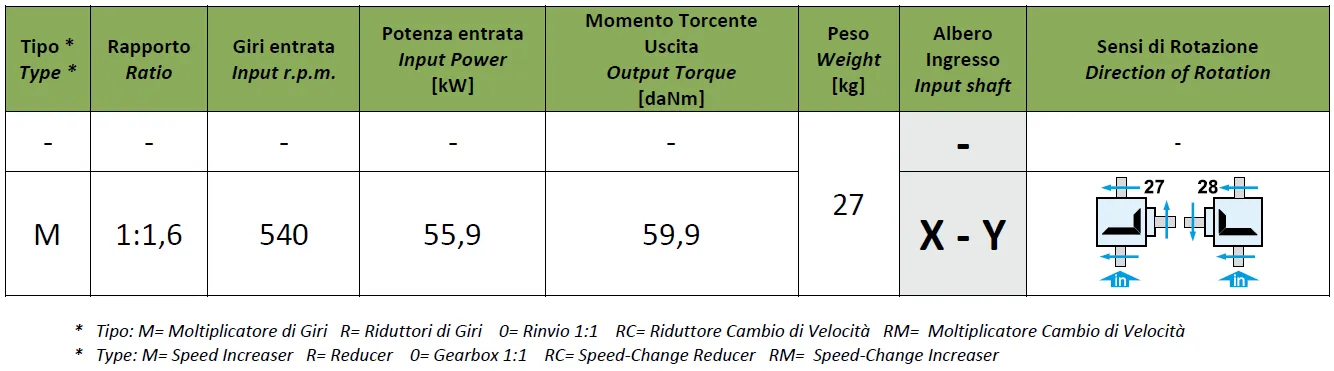

Agricultural PTO Shaft for Flail Mower Gearbox

The Agricultural PTO Shaft for Flail Mower Gearbox is an essential component designed to transfer power from the tractor’s PTO (Power Take-Off) to the flail mower gearbox. This power transfer enables the flail mower to operate efficiently, ensuring that vegetation such as grass, weeds, and light brush is effectively shredded. Below are the key features and benefits of the PTO shaft specifically designed for use with flail mower gearboxes:

Robust Power Transmission

The PTO shaft is engineered to transmit power from the tractor’s PTO system to the flail mower gearbox, ensuring optimal performance in various agricultural and landscaping tasks. It is designed to handle high torque levels and power demands, especially when cutting through dense vegetation. The shaft is equipped with high-quality universal joints that allow for smooth rotation and minimal power loss during operation.

Durable and Heavy-Duty Construction

Constructed with high-strength steel and premium materials, the agricultural PTO shaft is built to withstand the rigors of demanding fieldwork. It features heat-treated shafts, reinforced splines, and heavy-duty bearings, all contributing to a long-lasting, durable component that resists wear and tear. These design features ensure the shaft can operate reliably even under challenging conditions, such as tough terrain or thick brush.

Safety Features

The PTO shaft for flail mower gearboxes comes equipped with safety guards and shear bolts or torque-limiting devices. These features prevent the shaft from becoming overloaded, automatically disengaging in case of excessive resistance or mechanical failure, thus protecting both the tractor and the flail mower gearbox. Safety shields cover the rotating parts, minimizing the risk of injury to the operator or bystanders.

Easy Installation and Compatibility

The PTO shaft is designed for easy installation and seamless compatibility with a wide range of flail mower gearboxes. It features a quick-connect mechanism that allows for fast attachment and detachment from the tractor’s PTO output. Additionally, the shaft is available in various lengths and configurations, ensuring compatibility with different tractor models and flail mower gearboxes, providing flexibility for diverse applications.

Optimal Length and Flexibility

The PTO shaft is adjustable in length, allowing for flexibility in application. Whether the PTO system is being used with a small or large tractor, the adjustable shaft ensures that the correct distance between the tractor and the flail mower gearbox is maintained for optimal power transfer. The shaft’s flexibility also ensures smooth operation even on uneven or hilly terrain by accommodating slight shifts in the tractor’s position during operation.

The Agricultural PTO Shaft for Flail Mower Gearbox is a critical component for efficient and safe power transmission. Built for durability, ease of use, and high performance, this PTO shaft is designed to handle the demanding conditions of agricultural and landscaping tasks. It ensures smooth operation of the flail mower, enhancing its ability to tackle tough vegetation, while providing reliable and efficient service with minimal maintenance requirements. Whether you’re maintaining large fields or managing smaller garden spaces, the PTO shaft ensures your flail mower operates at its best.

|

|

How to Choose the Right Flail Mower Gearbox for Flail Mowers?

Selecting the right flail mower gearbox is crucial for ensuring optimal performance, durability, and efficiency in your mowing operations. The gearbox is responsible for transmitting power from the PTO shaft to the flail mower blades, enabling them to cut through vegetation effectively. Below are key factors to consider when choosing the right gearbox for your flail mower:

Understand the Gear Ratio

The gear ratio is one of the most important aspects of selecting the right flail mower gearbox. It determines the speed and torque delivered to the mower blades. The gear ratio is typically expressed as a ratio of input to output (e.g., 1:1.6, 1:2.91), and it affects both the cutting performance and the efficiency of the mower.

- A higher gear ratio (e.g., 1:2.91) provides more torque, making it ideal for cutting thicker vegetation or working in tough conditions.

- A lower gear ratio (e.g., 1:1.6) provides faster blade rotation, which is more suitable for mowing lighter grass or lawn areas.

Choose a gearbox with a gear ratio that matches the type of vegetation you intend to cut and the specific demands of your operation.

Power and Torque Requirements

Make sure the gearbox can handle the power output of your tractor’s PTO system. The torque rating of the gearbox should be compatible with the power you expect to deliver to the mower blades. If your tractor has a higher horsepower (HP), ensure the gearbox can handle the increased load without excessive wear or failure.

Flail mower gearboxes are generally rated by their power capacity (usually in horsepower or kilowatts) to match different tractor models. For example, a flail mower gearbox rated for 40 HP might be sufficient for light to medium-duty mowing, while a 100 HP-rated gearbox may be needed for heavy-duty, industrial tasks.

Durability and Construction Material

The durability of the gearbox is determined by the materials used in its construction and the quality of its engineering. Look for a flail mower gearbox made from high-quality steel or other durable alloys. This ensures the gearbox can withstand the physical stresses of frequent use in harsh conditions.

Additionally, consider a gearbox with reinforced gears and bearings. These features help reduce wear and extend the lifespan of the gearbox, especially when cutting dense vegetation or working in rugged terrain. Corrosion-resistant coatings are also an important feature, particularly for operations in wet or humid environments.

Compatibility with Your Mower and Tractor

It’s essential to choose a flail mower gearbox that is compatible with both your flail mower and your tractor’s PTO system. This includes considering the PTO shaft size, the input and output flange type, and the mounting configuration of the gearbox.

Flail mower gearboxes come in various sizes and designs to fit different models of mowers and tractors. Make sure the gearbox you choose aligns with the specific model and size of your mower to ensure seamless integration. Check the manufacturer’s specifications to verify compatibility.

Ease of Maintenance and Lubrication

Maintenance is an important consideration when choosing a flail mower gearbox. Gearboxes with easy-to-access lubrication points and sealed bearings are preferable because they reduce maintenance time and effort. Regular lubrication helps prevent overheating and reduces friction, ensuring the longevity of the gearbox.

Look for a gearbox with sealed housings that protect against dirt, debris, and water infiltration. Additionally, some gearboxes come with self-lubricating systems or oil pumps, making maintenance even easier.

Choosing the right flail mower gearbox requires a careful evaluation of factors such as gear ratio, power capacity, durability, compatibility, and maintenance requirements. By considering these key aspects and matching the gearbox to your specific mower and operational needs, you can ensure efficient, reliable, and long-lasting performance in your flail mowing tasks. Always prioritize quality, safety, and compatibility to achieve the best results and optimize your equipment’s longevity.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX