|

|

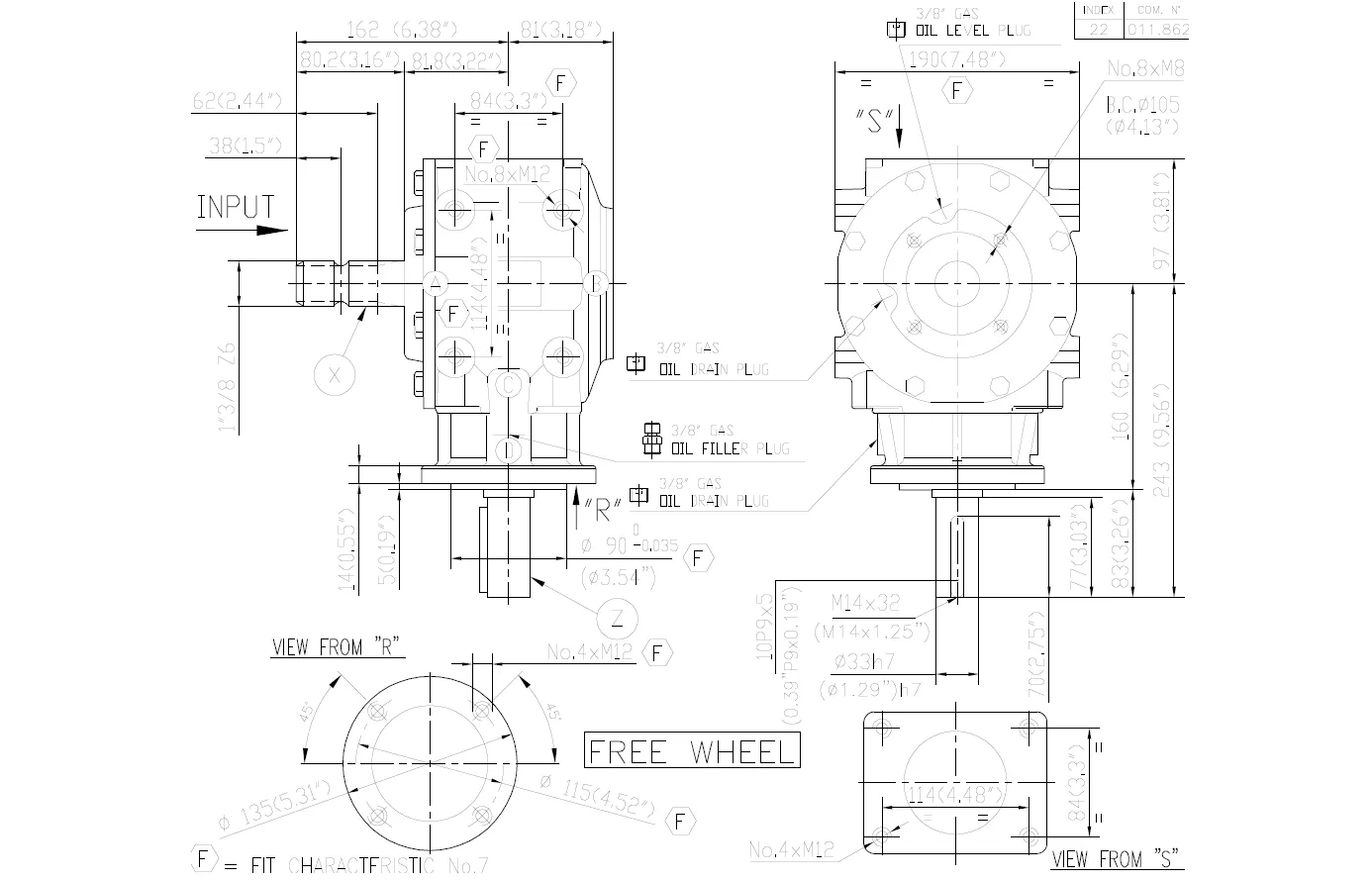

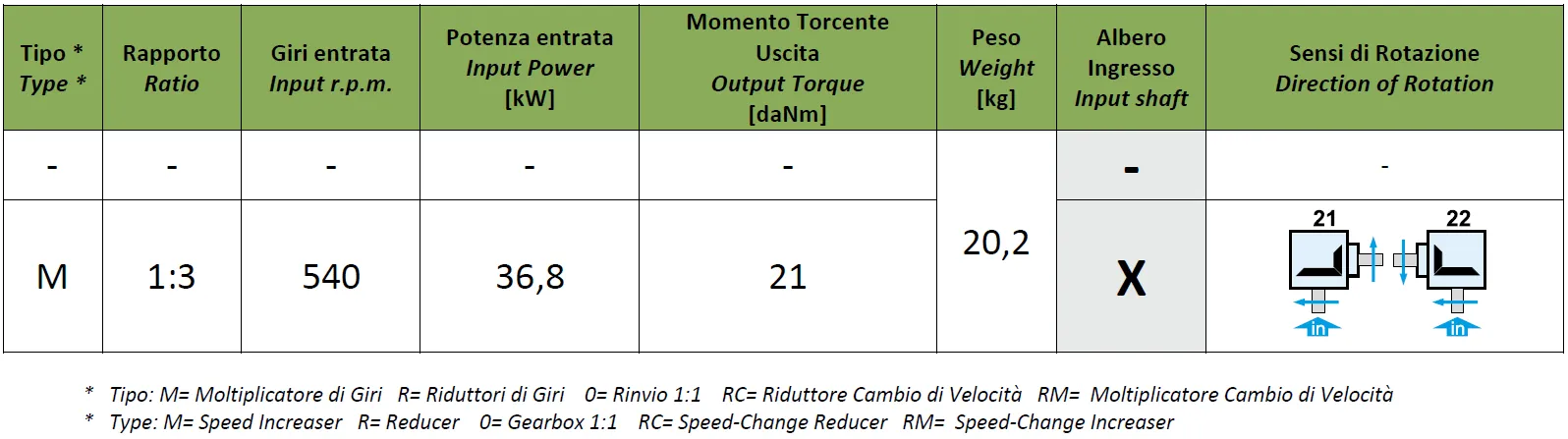

Specifications of Flail Mower Gearbox T-311J (1:3)

| Product Name |

Flail Mower Gearbox – Replacement of Comer Gearbox T-311J (1:3)

|

|---|---|

| Long description |

Gearbox with freewheel and only apply as an accelerator in the specified direction.

|

| Product details |

|

| Application range |

|

| Consists of |

|

| Contains oil |

No

|

| Max. oil capacity |

1.2 l

|

| Oil SAE viscosity grade |

80W-90

|

| Weight |

20.5 kg

|

| Gear arrangement Increasing |

21-22

|

| Input power kW / HP Increasing |

36.8 / 50 kW/HP

|

| Input shaft Increasing |

X

|

| Output Torque DaNm Increasing |

21 daNm

|

| Ratio Increasing |

1 : 3

|

| Shaft X |

1 3/8 Z6

|

| Shaft Z |

33H7

|

Characteristics of Flail Mower Gearbox T-311J

The Flail Mower Gearbox T-311J is a high-performance, durable gearbox designed for use in a variety of agricultural, landscaping, and heavy-duty mowing applications. Below are the key characteristics of the T-311J gearbox that make it an excellent choice for flail mowers:

High Torque and Power Transmission

The T-311J gearbox is designed to efficiently transmit high torque from the tractor to the mower blades, ensuring consistent and effective cutting performance even in tough conditions. With a well-calibrated gear ratio, the gearbox ensures that sufficient power is delivered to the mower’s rotor, allowing it to tackle dense grass, brush, and tough vegetation with ease. This high torque output reduces strain on the tractor, improving overall fuel efficiency and operational effectiveness.

Heavy-Duty Construction

Built with high-strength materials such as forged steel gears and reinforced housing, the T-311J gearbox is engineered to handle heavy-duty operations. The robust design ensures that the gearbox can withstand high stresses and impacts during use, offering excellent resistance to wear and tear. This heavy-duty construction makes the gearbox suitable for demanding environments, such as clearing thick brush or cutting through dense vegetation, while ensuring reliable and long-lasting performance.

Precision Engineering for Smooth Operation

The T-311J gearbox features precision-machined gears and advanced bearing systems that ensure smooth, quiet, and efficient operation. The optimized gear design reduces vibrations and noise during operation, leading to a quieter working environment and less wear on internal components. The smooth operation also prevents the buildup of excess heat, contributing to the gearbox’s durability and extending its service life.

Corrosion-Resistant Coatings

The T-311J gearbox is equipped with corrosion-resistant coatings to protect it from the elements, especially in outdoor conditions where moisture, dirt, and chemicals are prevalent. The corrosion resistance ensures that the gearbox maintains its integrity and performance even when exposed to challenging environments such as humid conditions, heavy rainfall, or dusty fields. This feature prolongs the life of the gearbox and reduces the need for maintenance and repairs.

Overload Protection

The T-311J gearbox comes with built-in overload protection to prevent damage during unexpected situations. For instance, if the mower encounters a hard obstacle (like a rock or a large tree stump), the gearbox’s overload protection feature disengages or limits the transmission of power, protecting both the gearbox and the tractor from damage. This safety feature helps to minimize the risk of gearbox failure and ensures that the machine remains operational under varying conditions.

The Flail Mower Gearbox T-311J stands out for its high torque transmission, heavy-duty construction, smooth operation, and corrosion-resistant design. It is an ideal solution for tackling tough mowing tasks in diverse agricultural and landscaping applications. With its overload protection, low maintenance requirements, and compact design, the T-311J gearbox provides a reliable, durable, and efficient solution for improving mowing productivity and ensuring the longevity of the equipment.

PTO Shaft for Flail Mower Gearbox

A PTO shaft (Power Take-Off shaft) is an essential component that connects the tractor to the flail mower gearbox, transmitting mechanical power from the tractor’s engine to the mower’s cutting mechanism. Proper selection and maintenance of the PTO shaft are crucial for ensuring the efficient operation and longevity of the flail mower system. Below are the key features and considerations for the PTO shaft for flail mower gearboxes:

Power Transmission Efficiency

The PTO shaft for flail mower gearboxes is designed to efficiently transmit power from the tractor’s PTO output to the gearbox, ensuring that the mower blades rotate at the correct speed to cut grass, brush, or other vegetation effectively. It is engineered to handle high torque and power demands, enabling the mower to operate at peak performance under various working conditions, from light mowing to heavy-duty brush clearing.

Durability and Heavy-Duty Construction

Flail mower PTO shafts are typically built with heavy-duty materials such as high-strength steel to withstand the mechanical stresses encountered during operation. The shaft is designed to endure harsh conditions such as shock loading, constant rotation, and exposure to dirt, moisture, and chemicals. Many PTO shafts feature a durable coating or corrosion-resistant treatment, ensuring longevity and reliability even in demanding agricultural and landscaping environments.

Customizable Lengths and Attachments

PTO shafts for flail mower gearboxes come in various lengths to accommodate different mower models and tractor configurations. The shaft must be adjusted to the appropriate length to ensure it fits securely between the tractor’s PTO output and the mower gearbox. PTO shafts often come with adjustable sections or telescoping designs that allow for easy modification of length, ensuring a proper fit and alignment for optimal power transmission.

Safety Features

Modern PTO shafts are equipped with various safety features to protect both the operator and the equipment. Common safety features include:

- Shear pins or torque-limiting devices: These safety mechanisms protect the PTO shaft and gearbox from overloads by disengaging if the system experiences excessive force, such as when hitting an obstacle.

- Safety shields: To prevent accidental contact with the rotating shaft, PTO shafts come with protective shields or covers that minimize the risk of injury.

- Quick-connect couplings: Many PTO shafts feature quick-connect mechanisms that allow for easy and secure attachment and detachment without the need for tools.

Universal Joint Compatibility

PTO shafts for flail mower gearboxes are often designed with universal joints (U-joints) at both ends to allow for flexible movement and ensure proper alignment between the tractor and the gearbox. The U-joints accommodate any slight misalignment of the PTO shaft while maintaining smooth, continuous power transmission. The flexible nature of U-joints helps prevent undue wear on the shaft, gearbox, and tractor PTO output, ensuring the longevity of all connected components.

The PTO shaft for flail mower gearboxes is a critical component in transmitting power from the tractor to the mower, enabling efficient cutting and operation. When choosing a PTO shaft, it is important to consider compatibility with the tractor and gearbox, as well as safety features, durability, and ease of maintenance. Regular maintenance, proper lubrication, and safety checks are essential to ensuring the longevity and reliability of both the PTO shaft and the mower gearbox, minimizing downtime and ensuring safe, efficient operation in all types of agricultural or landscaping tasks.

The Difference Between Flail Mower Gearbox and Rotary Mower Gearbox

Both flail mowers and rotary mowers are widely used for land maintenance, but their gearboxes differ in terms of design, application, and operation. These differences affect their performance, reliability, and maintenance needs. Here is a detailed comparison between the flail mower gearbox and the rotary mower gearbox:

Design and Operation

- Flail Mower Gearbox:

- The flail mower gearbox is designed to power a set of flail blades or hammers that are mounted on a rotating drum. These blades move in a swinging motion, effectively cutting and shredding vegetation into fine pieces.

- Gear Ratio: Flail mower gearboxes typically have a higher gear ratio (e.g., 1:1.89, 1:2.91) to provide the necessary power for swinging the heavy flail blades.

- The gearbox design is often robust, designed to handle the rotational forces required for cutting thick grass, brush, and even small trees.

- Rotary Mower Gearbox:

- The rotary mower gearbox powers a set of rotating blades (often flat, straight blades) mounted on a horizontal spindle or deck. These blades spin rapidly to cut vegetation in a similar manner to a traditional lawnmower.

- Gear Ratio: Rotary mower gearboxes generally have a lower gear ratio (e.g., 1:1.33 or 1:1.46) since the blade speed required is typically higher to achieve clean cutting results.

- The design of a rotary mower gearbox focuses on achieving high-speed rotation for smooth cutting of grasses, weeds, and light brush.

Cutting Mechanism

- Flail Mower Gearbox:

- The cutting action of a flail mower is achieved through the swinging motion of the flail blades, which can handle tougher vegetation like thick grass, small trees, and brush. The swinging action creates a mulching effect, leaving the shredded material behind.

- The gearbox must provide enough torque to move the flail blades with enough force to break down dense materials efficiently.

- Rotary Mower Gearbox:

- Rotary mowers cut through vegetation using spinning blades, which are similar to those found on most traditional lawnmowers. These blades rotate at high speeds to chop and cut the material, leaving behind clean, evenly cut grass.

- The gearbox in a rotary mower is designed to deliver higher rotational speeds to keep the blades spinning at optimal cutting speeds.

Power Requirements

- Flail Mower Gearbox:

- Due to the swinging motion of the blades, the flail mower gearbox requires more torque to move the heavier flail blades, especially when cutting through thicker, denser vegetation.

- The gearbox is built to handle heavy-duty tasks, making it ideal for land clearing or brush cutting, where higher torque is necessary.

- Rotary Mower Gearbox:

- The rotary mower gearbox is designed for speed rather than torque. Since the blades rotate rather than swing, the gearbox needs to deliver high-speed rotation rather than high torque.

- Rotary mowers are more suited for mowing lawns or cutting lighter grass and weeds, requiring less torque but higher rotational speed.

Maintenance and Durability

- Flail Mower Gearbox:

- Flail mower gearboxes are generally more rugged and built to handle heavy-duty usage. However, they require careful maintenance to ensure that the flail blades are correctly balanced, and the gearbox is properly lubricated and free of debris.

- The maintenance of a flail mower gearbox may involve inspecting the swinging blades, checking the oil, and ensuring that no obstructions cause the gearbox to overheat.

- Rotary Mower Gearbox:

- The maintenance of a rotary mower gearbox is typically simpler than that of a flail mower, as it is mainly designed to handle lighter cutting tasks. Regular checks of the oil levels, the blades, and the seals are required.

- Durability is generally sufficient for lighter applications, but rotary mower gearboxes may not be suitable for heavy brush clearing tasks.

Applications

- Flail Mower Gearbox:

- Flail mowers are commonly used in agriculture, landscaping, and forestry for heavy-duty applications such as brush cutting, grass clearing, and land reclamation.

- The gearbox is designed to provide the power needed for tough cutting tasks, handling thicker vegetation such as weeds, scrub, and small trees.

- Rotary Mower Gearbox:

- Rotary mowers are most commonly used for maintaining grass in lawns, golf courses, and pastures. They are also used for light to medium-duty brush cutting.

- The gearbox in rotary mowers is ideal for faster cutting, as it is designed for clean and even cuts of softer vegetation like grass and light weeds.

While both flail mower gearboxes and rotary mower gearboxes are designed to power mowing equipment, they differ in their cutting mechanisms, gear ratios, power requirements, and applications. The flail mower gearbox is built for heavy-duty tasks and can handle dense vegetation, requiring higher torque and offering a mulching effect. In contrast, the rotary mower gearbox is designed for higher rotational speeds and is best suited for maintaining grass and light brush, offering cleaner cuts.

Choosing the right gearbox depends on the type of vegetation being cut, the power requirements of the tractor, and the specific tasks to be performed.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX