|

|

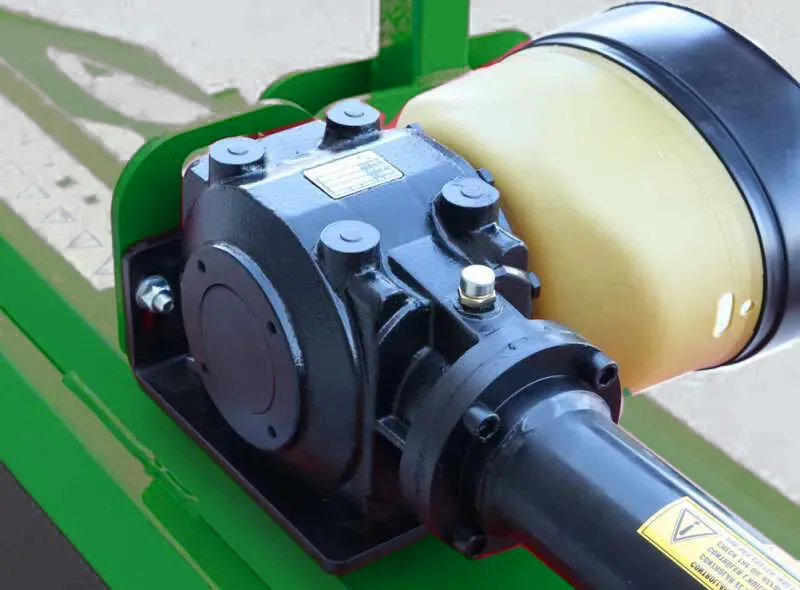

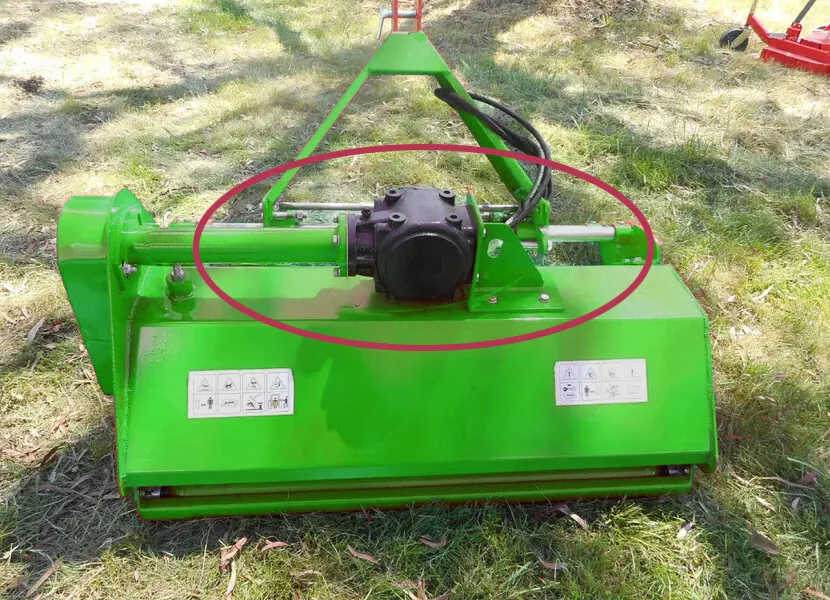

Specifications of Flail Mower Gearbox T-310A

| Product Description |

Flail Mower Gearbox – Replacement of Comer Gearbox T-310A

|

|---|---|

| Product details |

|

| Type |

RT1000

|

| Model |

T-310A

|

| Max. input power |

22.1 kW

|

| Max. input torque |

420 nm

|

| Max. output torque |

12.6 daNm

|

| Connection 1 type |

Splined

|

| Connection 2 type |

n/a

|

| Contains oil |

No

|

| Max. oil capacity |

0.8 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

| Original number equivalent |

310702

|

| Weight |

18 kg

|

| Gear arrangement Increasing |

21 – 22

|

| Gear ratio |

1 : 3

|

| Input shaft Increasing |

X

|

| Input shaft Reducing |

Z

|

| Output Torque DaNm Increasing |

12.6 daNm

|

| Ratio Increasing |

1 : 3

|

| Ratio Reducing |

3 : 1

|

| Shaft X |

1 3/8″ (6) Z6

|

| Shaft Z |

33 h7

|

Features of Flail Mower Gearbox T-310A

The Flail Mower Gearbox T-310A is designed for use in heavy-duty flail mower applications, offering advanced features that ensure reliable performance, durability, and efficiency. Here are the key features of the T-310A gearbox:

High Gear Ratio for Optimal Blade Speed

The T-310A gearbox is engineered with an optimal gear ratio that provides the right balance between speed reduction and torque increase. This gear ratio allows the mower blades to operate at the correct speed for efficient cutting, while also providing sufficient torque to handle tough mowing conditions, such as dense grass, brush, and weeds. The power transmission is smooth and effective, ensuring that the blades cut cleanly and uniformly.

Durable Construction for Heavy-Duty Use

Built to withstand the demands of heavy-duty agricultural and landscaping tasks, the T-310A gearbox is constructed using high-strength, heat-treated steel and precision-machined components. This robust design ensures that the gearbox can handle high-torque loads without compromising its performance or lifespan. The gearbox is highly resistant to wear and tear, making it suitable for continuous operation in tough environments.

Precision-Machined Gears for Smooth Operation

The T-310A features precision-machined gears that minimize friction, ensuring smooth operation with reduced noise and vibration. The high-quality gears contribute to efficient power transfer and help extend the life of the gearbox. This results in quieter operation, reducing operator fatigue and improving overall user experience during long working hours.

Heavy-Duty Bearings for Reliability

Equipped with heavy-duty bearings, the T-310A gearbox ensures high load capacity and long-term reliability. These bearings are designed to operate in high-stress environments, providing smooth rotational movement without excessive wear. The heavy-duty bearings also help absorb shock loads, improving the overall performance of the gearbox and reducing the risk of premature failure.

Compact and Easy-to-Install Design

The T-310A gearbox is designed with a compact and user-friendly structure, making it easy to install and integrate with various flail mowers. Its design allows for quick and simple installation onto the mower frame, reducing downtime during setup. Additionally, the compact size does not add unnecessary weight to the mower, maintaining its maneuverability and overall efficiency during operation.

The Flail Mower Gearbox T-310A stands out for its high durability, smooth operation, and reliable performance under demanding conditions. With features such as a high gear ratio, heavy-duty bearings, overload protection, and corrosion resistance, it is designed to provide efficient and long-lasting power transmission for flail mowers. Whether for agricultural, landscaping, or brush clearing tasks, the T-310A gearbox ensures optimal performance, minimal maintenance, and a longer service life, making it a valuable component for a variety of mowing applications.

Advantages of Flail Mower Gearbox T-310A

The Flail Mower Gearbox T-310A offers numerous advantages, making it a highly efficient and reliable choice for various agricultural, landscaping, and maintenance tasks. Below are the key benefits of using the T-310A gearbox:

Efficient Power Transmission

The T-310A gearbox is designed with an optimal gear ratio that ensures efficient power transmission from the tractor to the mower blades. This reduces the energy loss during operation and maximizes cutting efficiency. The gearbox provides the correct balance of torque and speed to ensure that the mower blades operate effectively, especially when cutting dense grass, brush, or heavy vegetation. This leads to improved fuel efficiency and better overall performance.

Durability and Longevity

Built with high-strength materials such as heat-treated steel and precision-machined gears, the T-310A gearbox is designed to withstand the rigors of heavy-duty use. Whether you are clearing dense brush, mowing thick grass, or handling tough conditions, the robust construction ensures that the gearbox can handle high torque and pressure without failure. This durability translates into longer service life and reduced downtime due to fewer repairs and replacements.

Smooth and Quiet Operation

The T-310A gearbox features precision-machined gears and heavy-duty bearings that minimize friction, resulting in smooth operation with reduced noise and vibrations. This ensures that the gearbox runs efficiently, reducing wear on internal components. The reduced noise level contributes to a quieter working environment, which helps reduce operator fatigue, especially during extended mowing sessions. The smooth operation also prevents the buildup of heat, extending the life of the gearbox.

Overload Protection for Safety

One of the standout features of the T-310A gearbox is its built-in overload protection system. This feature is essential when working in challenging environments where obstacles, such as rocks or dense debris, may cause the mower to become obstructed. The overload protection prevents damage to the gearbox and tractor by disengaging or limiting power transmission when excessive force or resistance is detected. This not only protects the equipment but also enhances safety for the operator during operation.

Low Maintenance Requirements

The T-310A gearbox is designed to be low-maintenance, thanks to its high-quality bearings, precision gears, and corrosion-resistant coatings. Routine maintenance, such as periodic lubrication and basic inspections, is typically sufficient to keep the gearbox running at peak performance. This reduces maintenance costs and downtime, allowing the operator to focus on their work without worrying about frequent repairs or part replacements. Its durability ensures that the gearbox can continue to perform for long periods with minimal attention.

The Flail Mower Gearbox T-310A offers numerous advantages, including efficient power transmission, durability, smooth operation, and overload protection, making it an ideal choice for demanding agricultural and landscaping tasks. Its low maintenance, corrosion resistance, and versatility further enhance its appeal, while the compact design and improved cutting performance ensure that it provides both high performance and ease of use. Whether used in commercial or residential applications, the T-310A gearbox is designed to deliver reliable, long-lasting performance under challenging mowing conditions.

|

|

Flail Mower Gearbox Oil Lubrication

Proper oil lubrication is crucial for maintaining the performance, longevity, and efficiency of a flail mower gearbox. Lubrication reduces friction between the gearbox components, prevents overheating, and protects internal parts from wear and corrosion. Below are key points to consider regarding the oil lubrication of flail mower gearboxes:

Choosing the Right Gearbox Oil

The first step in proper lubrication is selecting the appropriate oil for your flail mower gearbox. Typically, EP (Extreme Pressure) gear oil with the correct viscosity is recommended for flail mower gearboxes. The specific oil type will depend on the manufacturer’s recommendations, which can usually be found in the user manual. The common viscosity grades for gearboxes are SAE 90 or SAE 80W-90, though always refer to the manufacturer’s guidelines to ensure optimal performance.

Checking the Oil Level

Maintaining the correct oil level is essential for the gearbox’s smooth operation. Insufficient oil can lead to increased friction, causing overheating and accelerated wear of the gearbox components. Always check the oil level before each use of the mower. If your gearbox is equipped with an oil sight glass or a dipstick, use it to monitor the oil level and ensure it falls within the recommended range. If the level is low, top up with the specified oil until it reaches the correct level.

Changing the Gearbox Oil

Over time, gearbox oil can degrade and become contaminated with dirt, metal particles, or moisture. It is essential to change the oil at regular intervals to prevent damage to the gearbox. Most manufacturers recommend changing the oil after the first 20-50 hours of use, and then at intervals of around 100-200 hours thereafter. Be sure to drain the old oil completely, replace the drain plug, and refill the gearbox with fresh oil, ensuring it is the correct type and viscosity for your specific model.

Oil Filter Maintenance (If Applicable)

Some advanced flail mower gearboxes may be equipped with an oil filter to further protect the oil and internal components from contaminants. If your gearbox has an oil filter, be sure to inspect and replace the filter at the recommended intervals. A clogged or dirty oil filter can reduce the efficiency of lubrication and lead to premature wear of the gearbox components.

Avoiding Overfilling

While it is important to maintain the correct oil level, overfilling the gearbox can cause problems as well. Excess oil can lead to excessive pressure within the gearbox, which may cause leakage or foaming of the oil. Foamy oil loses its ability to lubricate effectively, which can result in damage to the gears and bearings. Always ensure that the oil level is correct according to the manufacturer’s specifications.

Proper lubrication of a flail mower gearbox is essential for maintaining its performance and longevity. By selecting the correct oil, checking the oil level regularly, changing the oil at recommended intervals, and maintaining the oil filter and seals, you can ensure that your flail mower gearbox operates efficiently and has a long service life. Regular lubrication maintenance also helps prevent unnecessary breakdowns and extends the time between repairs, saving both time and money in the long run. Always consult the manufacturer’s guidelines to ensure optimal care for your specific model.

About FMP

Headquartered in Italy, FMP is a leading manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, primarily for the agricultural machinery sector. Renowned for our precision engineering, innovation, and unwavering reliability, FMP has established itself as a trusted partner in meeting the evolving demands of both the agricultural and industrial markets. Our comprehensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other critical components, all designed to provide effective, customized solutions across a wide range of applications.

At FMP, we understand that every client has unique needs and challenges. This is why we specialize in offering tailored solutions, whether through individual components or fully integrated systems. We take a collaborative approach, working closely with our customers to ensure that each solution is not only effective but also efficient. Our commitment to fast, professional responses and expert guidance guarantees that every inquiry is handled with the utmost care and precision, ensuring the best outcomes for our clients.

We place a strong emphasis on open and ongoing communication, particularly in the development of new products. Our dedicated team works directly with clients to fully understand their requirements, offering valuable insights and recommendations that lead to optimal solutions. Whether we are designing innovative products or fulfilling existing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time, ensuring that our clients receive the best service and results.

At the core of FMP’s operations is our relentless focus on quality. We adhere to the highest manufacturing standards, employing stringent quality control measures to ensure that every product not only meets but exceeds industry expectations. This commitment to quality, coupled with our core values of integrity, teamwork, and perseverance, has allowed us to build lasting, trusting relationships with customers in nearly 30 countries around the world.

FMP is always eager to build global partnerships and remains dedicated to providing expert guidance and custom solutions to meet the diverse needs of our clients. Our approach goes beyond merely delivering products; we aim to cultivate long-term relationships that contribute to the success of every project. Whether you require innovative solutions for a new venture or ongoing support for an existing system, FMP is here to address your technical challenges and help ensure your sustained success.

Author: CX