|

|

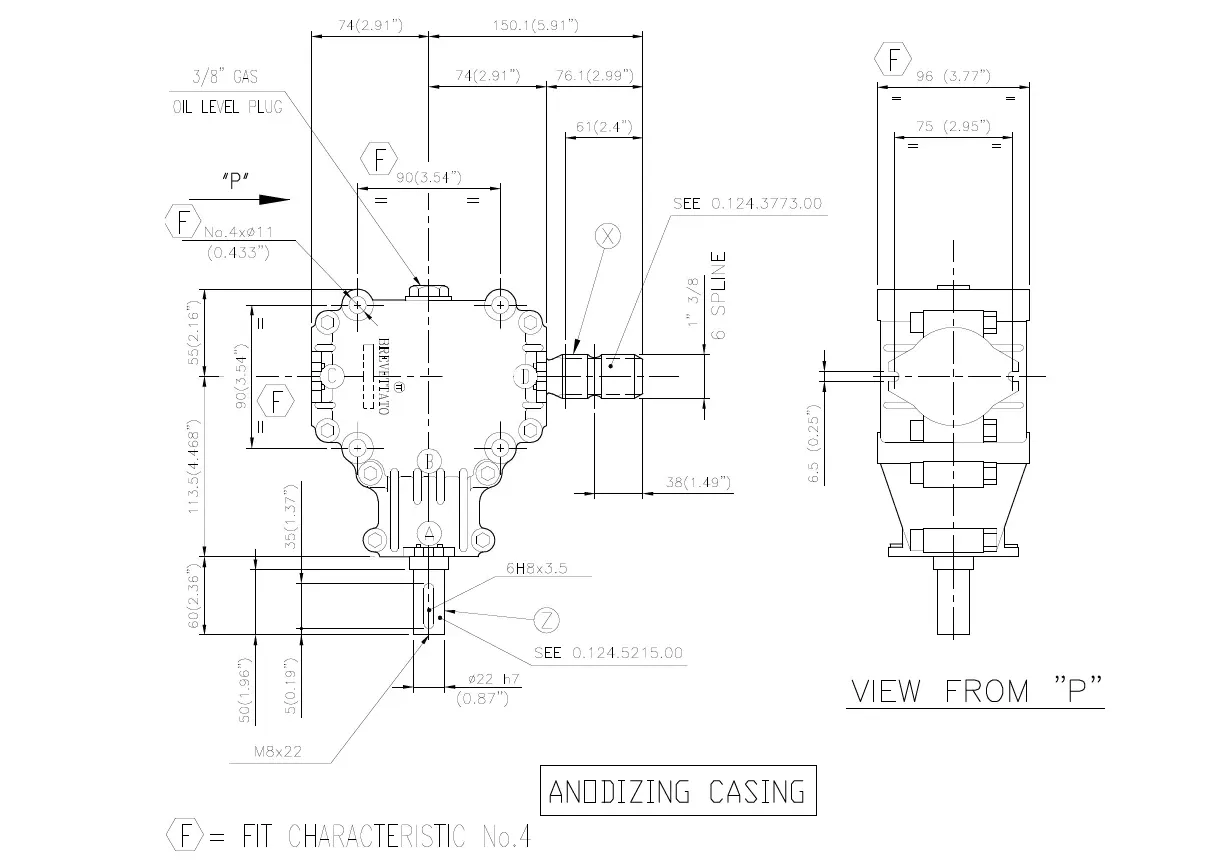

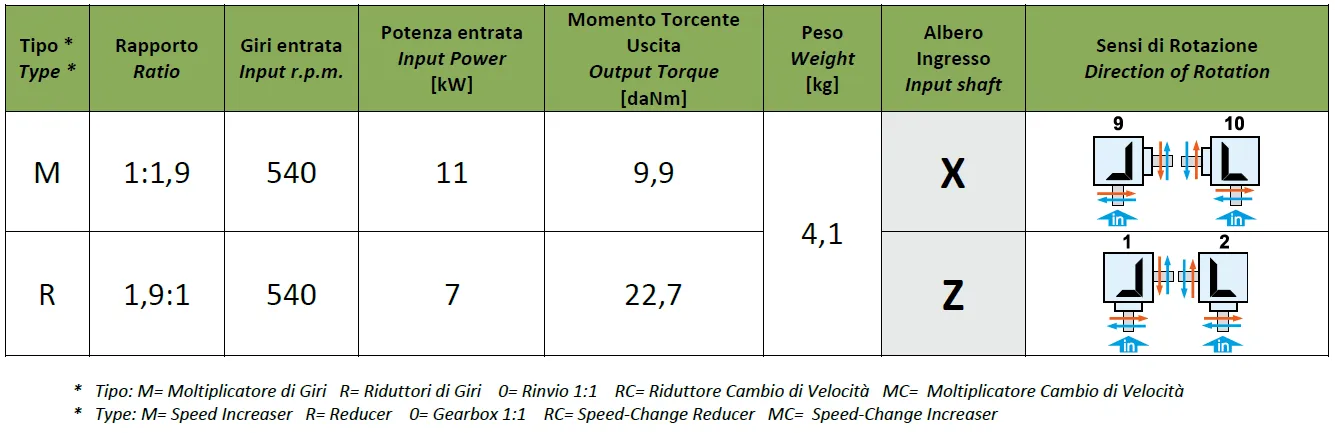

Specifications of Flail Mower Gearbox L-25J (1:1.9)

| Description |

Flail Mower Gearbox – Replacement of Comer Gearbox L-25J 1:1.9

|

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

| Max. output torque |

22.7 daNm

|

| Contains oil |

No

|

| Max. oil capacity |

0.35 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Aluminium

|

| Weight |

4.1 kg

|

| Gear arrangement Reducing |

1 – 2

|

| Input power kW / HP Increasing |

11 / 15 kW/HP

|

| Input shaft Increasing |

X

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

7 / 9.5 kW/HP

|

| Output Torque DaNm Increasing |

9.9 daNm

|

| Ratio Increasing |

1: 1.9

|

| Ratio Reducing |

1.9: 1

|

| Shaft X |

1 3/8″ (6) (A)

|

| Shaft Z |

22 (D)

|

How to Choose the Right PTO Shaft for Flail Mower Gearbox

Selecting the appropriate PTO shaft for a flail mower gearbox is crucial for ensuring efficient and safe operation. A well-chosen PTO shaft will provide optimal power transfer, improve the mower’s performance, and extend the lifespan of both the PTO shaft and the mower gearbox. Here are key considerations to guide you in selecting the right PTO shaft for your flail mower:

Match the PTO Shaft Length to the Equipment

One of the most important factors when choosing a PTO shaft is ensuring it has the correct length to fit your tractor and flail mower. A telescoping PTO shaft offers the flexibility to adjust its length, which is especially important when you work with different tractor and mower combinations. If the shaft is too short, it can put unnecessary strain on the components; if it’s too long, it could cause excess vibration or even disengage during operation. Ensure that the shaft length allows for proper connection, even when the tractor and mower move through their full range of motion.

Check the PTO Shaft Torque Rating

The PTO shaft must be capable of handling the torque requirements of your flail mower. This is particularly important if you are working in tough conditions, such as dense grass, heavy brush, or stony ground. Each PTO shaft is rated for a specific torque range, so it’s crucial to choose one that matches the power output of your tractor and the demands of your mower gearbox. Overloading the shaft can lead to premature wear, damage to the components, or even failure. Always ensure the PTO shaft torque rating aligns with the power output of your tractor and the mower’s cutting requirements.

Compatibility with PTO and Gearbox Connections

Make sure that the PTO shaft is compatible with the tractor’s PTO output and the flail mower’s gearbox input. PTO shafts come in different connection types, such as standard (six-spline), profile (single/double universal joint), and constant velocity (CV). The connection type must match both the tractor and the flail mower gearbox to ensure a secure, stable, and efficient power transfer. Verify the diameter and spline count of both the tractor’s PTO shaft and the mower gearbox input to ensure proper fit.

Consider the Shaft’s Duty Rating

PTO shafts are typically classified into different duty ratings: light, medium, and heavy-duty. The choice of duty rating depends on the type of work the flail mower will be doing. For example, medium-duty shafts are typically used for lighter mowing tasks, while heavy-duty shafts are required for more demanding applications such as clearing thick brush or heavy vegetation. If you frequently operate in challenging environments or need the flail mower to handle substantial loads, opt for a heavy-duty PTO shaft that is designed for maximum durability and performance.

Safety Features

Safety is paramount when using agricultural equipment, so make sure that the PTO shaft comes with appropriate safety features. Look for shafts equipped with safety shields, which cover the rotating parts to prevent accidental contact. In addition, check for overload protection mechanisms such as shear bolts, torque limiters, or clutches, which can help protect the tractor, gearbox, and PTO shaft from damage in the event of sudden obstructions or excessive load. These features enhance operator safety and prevent costly repairs due to overloading.

Choosing the right PTO shaft for your flail mower gearbox is essential for ensuring smooth, efficient, and safe operation. Consider factors such as shaft length, torque rating, compatibility, and safety features to select the correct PTO shaft for your specific equipment. By ensuring that the PTO shaft is properly matched to your tractor and mower, you’ll optimize power transmission, enhance mowing performance, and reduce the likelihood of costly maintenance or repairs. Always prioritize quality, durability, and safety to maximize the lifespan and productivity of your agricultural equipment.

|

|

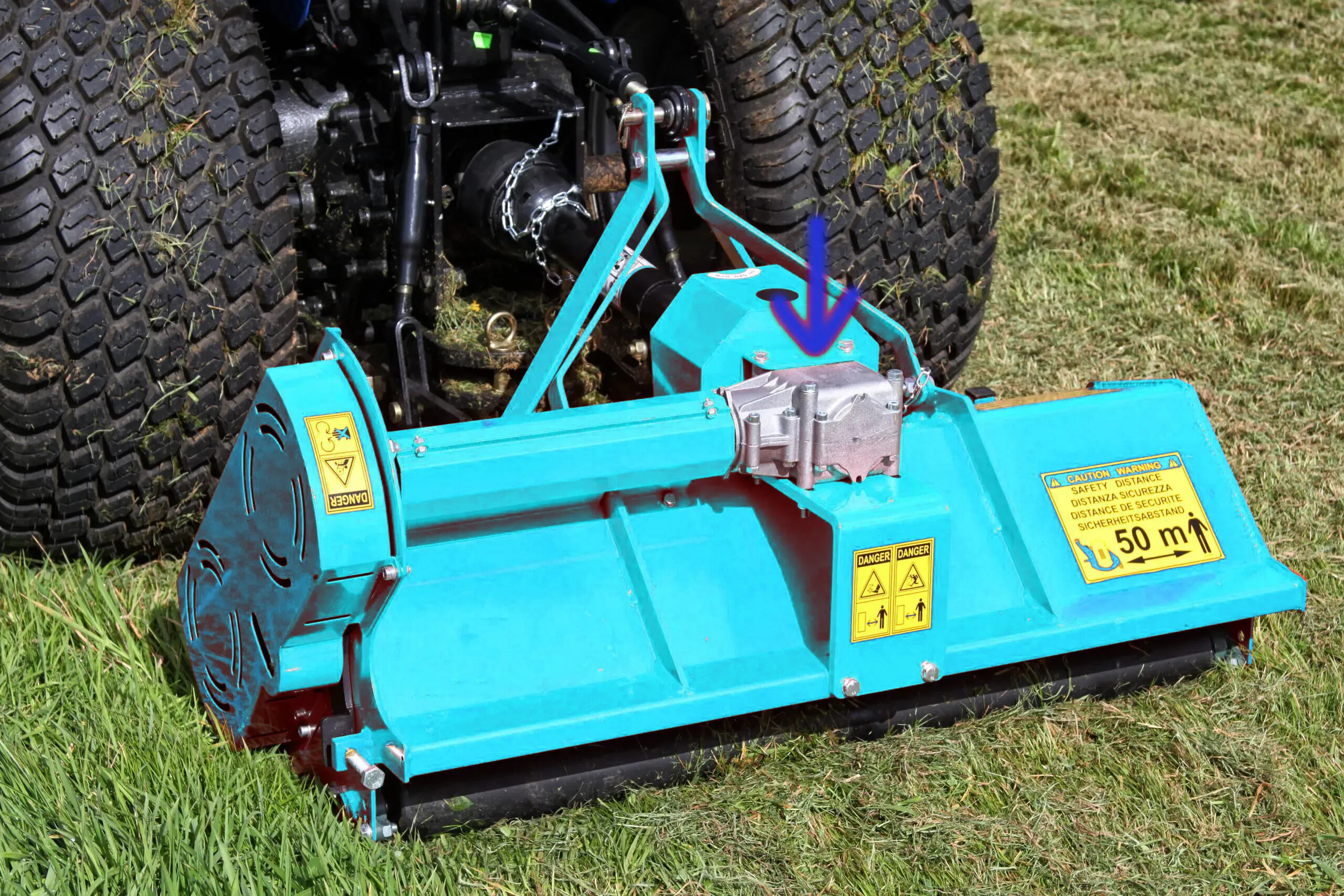

How Does the Flail Mower Gearbox Work?

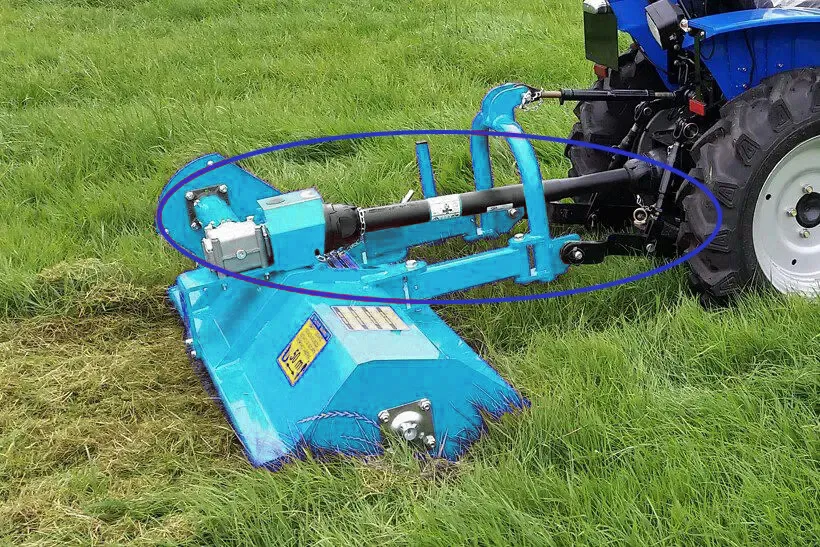

The flail mower gearbox plays a critical role in converting the power provided by the tractor’s PTO (Power Take-Off) into the rotational energy required to operate the mower blades. It helps control the speed, torque, and direction of the blades to ensure effective and consistent cutting performance. Here’s how a typical flail mower gearbox works:

Power Transfer from Tractor to Gearbox

When a tractor is connected to a flail mower, the PTO shaft of the tractor transfers mechanical power to the flail mower’s gearbox. The tractor’s engine provides rotational power, which is delivered through the PTO shaft to the input shaft of the gearbox. The gearbox receives this input power, which is often at a high RPM (rotations per minute) from the tractor, and begins the process of converting it into the necessary output for the mower blades.

Torque and Speed Reduction

The gearbox is designed to reduce the high rotational speed from the PTO shaft to a more appropriate speed for the mower blades. The high RPM from the tractor’s PTO is typically too fast for the flail mower to operate efficiently, so the gearbox contains a series of gears that reduce the speed and increase the torque. This reduction in speed ensures that the mower blades operate at an optimal cutting speed, while the increased torque provides the necessary power to cut through thick vegetation, grass, or brush.

Power Distribution to the Mower Blades

After reducing the speed and increasing the torque, the gearbox distributes the rotational power to the mower blades via the output shaft. The output shaft is typically connected to a set of rotating flails or blades that cut vegetation. Depending on the design, the gearbox may use direct or bevel gears to distribute power evenly across the blades. This ensures that all the blades rotate at a consistent speed, providing uniform cutting performance across the entire cutting width of the mower.

Adjustable Speed and Direction (Optional)

Some advanced flail mower gearboxes allow for the adjustment of the speed and direction of the mower blades. This feature is particularly useful for specific tasks like adjusting the cutting height or switching between different cutting conditions. Gearboxes with multiple output shafts or variable gear settings enable the operator to fine-tune the mower’s performance to achieve the desired results. This adjustability also helps with more efficient operation in varying terrain and vegetation conditions.

Safety Mechanisms

To protect the gearbox and tractor from overload or sudden impact, many flail mower gearboxes incorporate safety mechanisms like shear pins or overload clutches. These mechanisms are designed to disengage the power transmission if the blades encounter an obstruction, such as a large rock or thick piece of debris. This prevents damage to the gearbox, PTO shaft, or mower blades, helping to ensure that the system remains operational even in harsh conditions.

In summary, the flail mower gearbox is a key component in converting the power from the tractor’s PTO into the correct speed and torque to operate the mower blades. It reduces the high rotational speed from the tractor and ensures that the blades rotate at an optimal speed for cutting grass, brush, or other vegetation. The gearbox may also include safety mechanisms and features that allow for speed and direction adjustments, making it a versatile and essential part of the flail mower’s operation. Regular maintenance, including lubrication and checking for wear, is necessary to keep the gearbox functioning properly and to extend its lifespan.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX