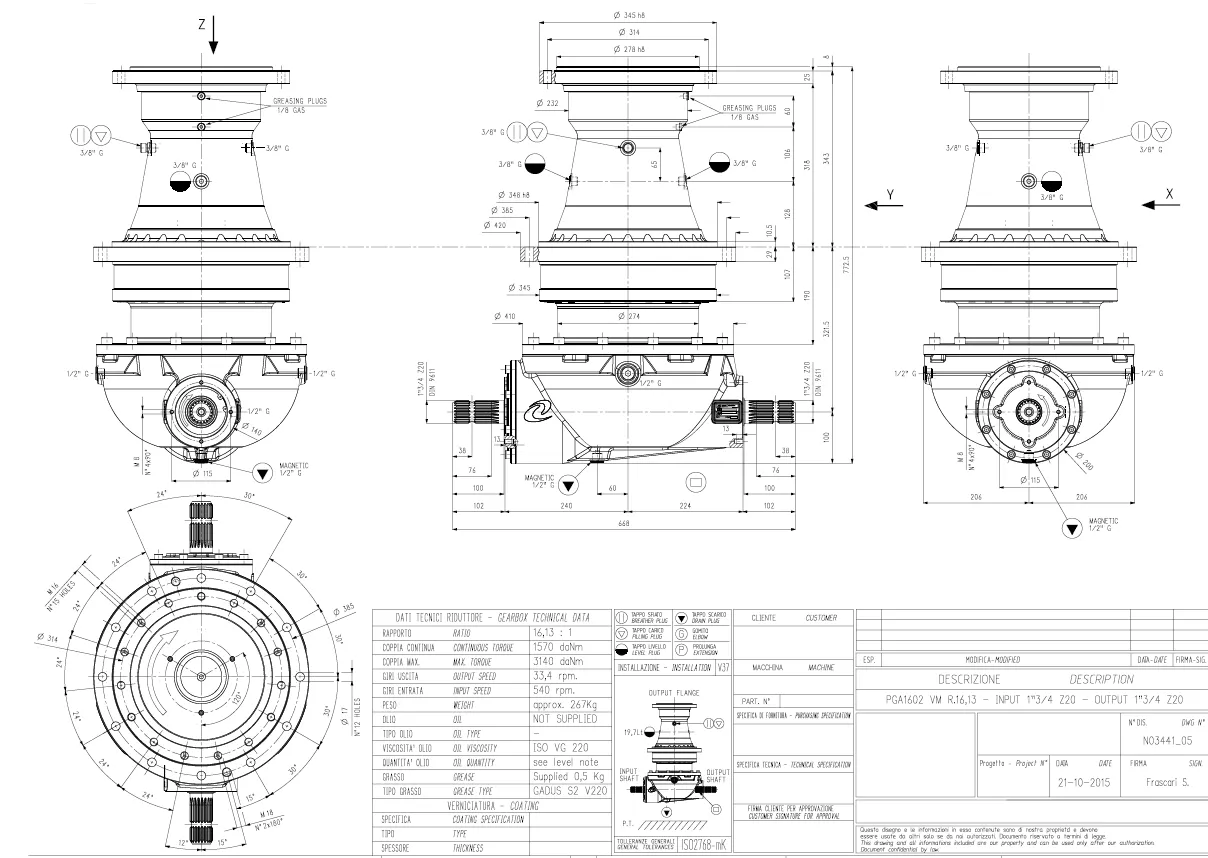

Feed Mixer Machines Gearbox PGA-1602 Specifications

| Description |

Feed Mixer Machines Gearboxes – Replacement of Comer Code PGA-1602

|

|---|---|

| Specifications |

Has a special bearing complete where the screw spindle can be directly connected.

|

| Benefits |

No separate bearing complete required for the winch

|

| Application |

|

| Consists of |

|

| Model |

PGA 1602

|

| Max. output rotation speed |

29 r/min

|

| Max. output torque |

15700 nm

|

| Max. output torque |

1570 daNm

|

| Contains oil |

No

|

| Oil SAE viscosity grade |

90EP

|

| Weight |

265 kg

|

| Gear ratio |

16.1:1

|

| Input power KW / HP Reducing |

88.7 kW/HP

|

| Ratio Reducing |

16,2:1

|

| Shaft type |

2 x 1.3/4 (Z20)

|

Feed Mixer Machines Gearbox PGA-1602 Dimensions

Features of Feed Mixer Machines Gearbox PGA-1602 for Mixing Wagon

The PGA-1602 Feed Mixer Gearbox is an essential component designed specifically for use in mixing wagons. It provides the necessary mechanical power to efficiently mix animal feed and other materials, ensuring uniform distribution and optimal performance. Below are the key features of the PGA-1602 Gearbox:

Robust Construction for Heavy-Duty Use

- Durability: The PGA-1602 gearbox is built to handle the demands of heavy-duty agricultural operations. Made with high-strength materials, it can withstand high torque and frequent use in tough agricultural environments, ensuring reliable performance over extended periods.

- Importance: The heavy-duty construction guarantees that the gearbox can endure the mechanical stress associated with mixing large quantities of feed, making it a durable choice for demanding farming tasks.

High Power Transmission Efficiency

- Efficient Power Transfer: The PGA-1602 gearbox is engineered to provide efficient power transmission from the tractor’s PTO shaft to the feed mixer machine. With optimized gear ratios and a well-designed gear mechanism, it ensures smooth operation and effective mixing.

- Importance: High power transmission efficiency reduces energy losses, ensuring that the mixing process is completed with minimal fuel consumption and maximum output.

Compact and Space-Saving Design

- Compact Structure: The gearbox is designed with a compact form factor, allowing it to be easily integrated into the feed mixer system without taking up unnecessary space.

- Importance: This space-saving design allows for better weight distribution and easier mounting on the mixing wagon, making it an ideal choice for agricultural applications where space is at a premium.

Enhanced Mixing Performance

- Precise Gear Ratios: The PGA-1602 gearbox features carefully calibrated gear ratios that ensure the optimal rotational speed and torque are delivered to the feed mixer augers or paddles.

- Importance: The precise power output ensures that feed ingredients are thoroughly mixed, promoting uniformity and consistency in the final feed mixture. This improves the efficiency of the feeding process and reduces waste.

Easy Maintenance and Lubrication

- Low Maintenance Design: The gearbox is designed for easy maintenance, with simple access points for regular checks and lubrication. The enclosed system minimizes the need for frequent repairs and helps to extend the gearbox’s service life.

- Importance: Reduced maintenance time and ease of lubrication improve operational efficiency and reduce downtime, allowing farmers to focus on other tasks.

The PGA-1602 Feed Mixer Gearbox offers a range of features that enhance the performance, durability, and efficiency of mixing wagons. With its robust construction, high power transmission efficiency, and ease of maintenance, it is an ideal choice for agricultural operations looking to optimize their feed mixing processes. Whether it is for small-scale or large-scale livestock feeding, the PGA-1602 gearbox ensures smooth, consistent, and reliable operation, contributing to the overall success of feeding operations.

Working Principle of Feed Mixer Gearbox PGA-1602 for Mixing Wagon

The PGA-1602 Feed Mixer Gearbox plays a critical role in the operation of mixing wagons by transferring power from the tractor’s PTO (Power Take-Off) shaft to the mixing augers or paddles inside the wagon. It ensures efficient mixing of various feed ingredients, delivering a uniform and consistent mixture. Below is a detailed breakdown of how the PGA-1602 Gearbox works:

Power Transmission from PTO Shaft

- Initial Power Transfer: The feed mixer gearbox is connected to the PTO shaft of a tractor. When the tractor’s engine is running, the PTO shaft rotates and delivers mechanical power to the gearbox.

- Gearbox Input: The gearbox receives the rotational energy from the PTO shaft via its input shaft, which is the first point where power is received.

Gear Mechanism and Torque Conversion

- Internal Gear System: Inside the PGA-1602 gearbox, a series of gears (usually bevel or helical) are used to reduce or increase the rotational speed, depending on the gear ratio. These gears convert the input power into the required torque and rotational speed for the feed mixer.

- Power Adjustment: The gearbox adjusts the power from the PTO shaft by changing the gear ratios, ensuring that the correct amount of torque is delivered to the augers or paddles inside the mixing wagon. Typically, a lower gear ratio results in higher torque and slower speed, ideal for mixing heavy materials, while a higher gear ratio increases the speed for lighter mixes.

Output Power to Mixing Mechanism

- Drive to Augers or Paddles: The adjusted power (torque and speed) is transmitted from the output shaft of the gearbox to the mixing augers or paddles of the feed mixer. This is achieved through a coupling mechanism that connects the gearbox’s output shaft to the auger’s shaft or paddle mechanism.

- Efficient Mixing: The rotating augers or paddles now perform the mixing action, rotating inside the mixing chamber to thoroughly mix feed ingredients. The movement of the augers ensures that all the ingredients are uniformly blended, resulting in a consistent and homogeneous feed mixture.

Continuous Operation with Power Delivery

- Constant Rotation: As long as the PTO shaft is engaged and the tractor’s engine is running, the gearbox will continuously transmit power to the mixing mechanism. The augers or paddles rotate and move the feed ingredients around the mixing chamber.

- Optimal Performance: The feed mixer gearbox ensures that the mixer operates at optimal speed and torque, maintaining constant power delivery for effective and efficient feed mixing, even under varying load conditions.

Safety and Control Features

- Overload Protection: In the event of excessive resistance or blockage within the mixer, the gearbox may incorporate overload protection systems to prevent damage. This system either disengages the PTO connection or activates a safety mechanism to stop the power transfer and protect the machinery.

- Lubrication and Maintenance: To keep the gearbox running smoothly, it requires regular lubrication to ensure that the gears move freely without excessive wear or heat buildup. Lubricants reduce friction, prolong the lifespan of the gearbox, and ensure reliable performance throughout its operation.

The PGA-1602 Feed Mixer Gearbox works by receiving power from the tractor’s PTO shaft and transmitting it through a series of gears to the feed mixer’s augers or paddles. It ensures that the mixing process operates at the correct speed and torque, allowing for optimal feed preparation. Through its efficient power transmission and built-in safety features, it plays a crucial role in achieving a consistent, uniform mixture of feed, which is essential for the health and productivity of livestock.

Applications of Feed Mixer Gearbox PGA-1602 for Mixing Wagon

The PGA-1602 Feed Mixer Gearbox is a highly versatile and essential component for agricultural machinery, particularly in the operation of mixing wagons. It plays a pivotal role in efficiently mixing and blending feed ingredients for livestock. Below are the key applications of the PGA-1602 Gearbox:

Livestock Feed Mixing

- Efficient Feed Preparation: The primary application of the PGA-1602 gearbox is in livestock feed mixing. It ensures that various feed ingredients, such as grains, hay, silage, and supplements, are mixed uniformly. This is crucial for providing livestock with a balanced and consistent diet, promoting their health and productivity.

- Homogeneous Mixture: The gearbox enables the augers or paddles in the mixing wagon to rotate at optimal speeds, resulting in a perfectly blended mixture of feed ingredients, which is vital for digestibility and nutritional balance.

Agricultural Feed Processing

- Customizable Feed Blending: The PGA-1602 gearbox is commonly used in agricultural operations where custom feed formulations are required. This includes farms that raise poultry, cattle, or pigs, where the feed needs to be adjusted to specific nutritional requirements based on growth stages or health conditions.

- Efficient Production of Specialized Feeds: The gearbox helps to achieve efficient mixing of specialized feed ingredients for specific animal breeds or farming practices, making it essential for agricultural feed processors.

Silage and Forage Mixing

- Forage and Silage Preparation: The PGA-1602 gearbox is widely used in the preparation of silage and forage feeds. It facilitates the mixing of chopped hay, straw, and other forage materials to create high-quality silage that is rich in nutrients and ideal for storing feed for winter months.

- Increased Nutritional Value: The gearbox ensures that these materials are evenly blended, which helps in preserving their nutritional content, making silage mixing more effective.

Custom Animal Diet Formulations

- Precision Mixing: For farms that require customized animal diets based on specific feeding programs, the PGA-1602 gearbox allows for the precise blending of ingredients. This is especially beneficial for farms with diverse animal populations or those engaged in research where feed formulations must be consistent and precise.

- Efficient Small-Scale Mixing: The gearbox enables smaller farms or research facilities to efficiently mix smaller quantities of customized feed, ensuring consistent quality across different batches.

Mobile and On-Farm Mixing Operations

- Mobile Mixing Wagons: Many agricultural operations rely on mobile feed mixers, which move from one location to another within a farm. The PGA-1602 gearbox is commonly used in these mobile mixing wagons, enabling them to operate effectively across large areas, ensuring that feed can be mixed on-site without the need for transportation.

- On-Site Feed Production: Farms benefit from the ability to mix feed directly on the field, reducing costs and time associated with transporting feed and ensuring that livestock receive fresh, custom-blended feed.

The PGA-1602 Feed Mixer Gearbox is indispensable in agricultural operations that require effective and uniform mixing of feed. Its key applications span from livestock feed preparation and forage mixing to customized animal diet formulations and mobile mixing operations. By ensuring consistency, efficiency, and precision in the mixing process, the PGA-1602 gearbox significantly contributes to the productivity and success of farms, feed processors, and animal breeders.

|

|

About FMP

Based in Italy, FMP is a premier manufacturer specializing in the design, development, and production of high-performance gearboxes, with a particular emphasis on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unmatched reliability, FMP has earned the trust of clients across both the agricultural and industrial sectors. Our extensive product portfolio includes specialized gearboxes for applications such as lawn mowers, PTO shafts, and a wide range of essential mechanical components, all engineered to provide customized solutions for diverse applications.

At FMP, we recognize that each client has unique needs and challenges. This is why we excel at delivering tailored solutions—whether it’s for individual components or fully integrated systems. We work closely with our customers to ensure that each solution is efficient, effective, and value-driven, optimizing both performance and cost-efficiency. With a commitment to fast, professional responses and expert guidance, we ensure that every customer inquiry is handled with the utmost care, leading to the most effective and beneficial outcomes.

We emphasize open and transparent communication throughout the product development process. Our dedicated team collaborates directly with clients to thoroughly understand their specific requirements, offering valuable insights and recommendations to deliver optimal solutions. Whether we are developing innovative products or fulfilling ongoing orders, FMP is committed to providing high-quality, precision-engineered solutions—on time, every time. Our goal is to surpass client expectations and deliver results that drive success.

At the heart of FMP’s operations is quality. We adhere to the highest manufacturing standards, with stringent quality control processes in place to ensure each product not only meets but exceeds industry benchmarks. This steadfast commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has helped us build lasting relationships with clients in over 30 countries worldwide.

FMP is always eager to foster global partnerships and remains focused on delivering expert advice and customized solutions tailored to meet the diverse needs of our clients. We go beyond simply supplying products—we build enduring relationships that contribute to the success of every project. Whether you require innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to help you tackle technical challenges and ensure continued success.

Author: CX