Specifications of Feed Mixer Gearbox C-3A

| Description |

Feed Mixer Machines Gearboxes – Replacement of Comer Code C-3A

|

|---|---|

| Product Details |

|

| Application |

Mixing wagon

|

| Consists of |

|

| Technical information |

All technical data corresponds to ISO 6335 and ISO 281

|

| Contains oil |

No

|

| Oil SAE viscosity grade |

80W-90

|

| Weight |

100 kg

|

| Input shaft Reducing |

1.3/4 Z20

|

| Input power KW / HP Reducing |

110 / 150 kW/HP

|

| Ratio Reducing |

1.28/2.3:1

|

Dimensions of Feed Mixer Gearbox C-3A

Feed Mixer Gearbox C-3A Structural Components

The Feed Mixer Gearbox C-3A is an essential component used in agricultural machinery, specifically designed for mixing feed for livestock. Below are the structural components of the C-3A Feed Mixer Gearbox, which contribute to its functionality and durability:

Gearbox Housing

- Description: The housing serves as the outer casing of the gearbox and is typically made from high-strength cast iron or steel for durability and protection against external damage.

- Function: It contains all the internal components, ensuring that they remain properly aligned and lubricated during operation. The robust housing prevents wear and tear, extending the lifespan of the gearbox.

Input Shaft

- Description: The input shaft is connected to the power source, such as a PTO shaft, which transmits rotational force from the tractor or motor to the gearbox.

- Function: The input shaft is designed to handle high torque levels, ensuring the efficient transfer of power from the engine to the internal gears of the gearbox.

Planetary Gear System

- Description: The C-3A gearbox typically features a planetary gear system, comprising a central sun gear, multiple planet gears, and a ring gear.

- Function: This gear system provides the necessary torque multiplication and speed reduction, allowing the feed mixer to operate at the optimal mixing speed for various types of feed.

Output Shaft

- Description: The output shaft is connected to the feed mixer’s auger or other moving parts that perform the mixing action.

- Function: It transmits the rotational motion from the gearbox to the internal mechanism of the feed mixer, driving the mixing blades or augers to blend the feed ingredients efficiently.

Bearings and Bushings

- Description: Bearings and bushings are used throughout the gearbox to reduce friction between moving parts and support the shafts and gears.

- Function: These components ensure smooth rotation of the gears and shafts, improving the efficiency of the gearbox and reducing the wear and tear caused by friction.

The Feed Mixer Gearbox C-3A combines these structural components to deliver efficient, reliable, and durable performance in feed mixing applications. By incorporating high-quality materials and design principles, it ensures smooth operation, effective power transfer, and long-lasting service, making it an essential part of modern livestock feeding systems.

Working Principle of Feed Mixer Gearbox for Mixing Wagon

The working principle of a feed mixer gearbox for a mixing wagon is based on the transmission of rotational power from a power source (typically a tractor’s PTO or an engine) through a series of gears to drive the mixer’s augers or paddles. The gearbox plays a crucial role in adjusting the speed and torque to ensure efficient mixing of feed ingredients. Here’s how it works in detail:

Power Transfer from the PTO to the Gearbox

- Input Shaft: The feed mixer gearbox is typically powered by a PTO shaft connected to a tractor or a motor. The PTO (Power Take-Off) shaft provides the rotational energy to the gearbox.

- Function: When the PTO is engaged, it transmits mechanical energy from the tractor’s engine to the gearbox, turning the input shaft at a specific speed and torque.

Torque and Speed Reduction

- Planetary Gear Set: Inside the gearbox, a planetary gear system or other types of gear mechanisms are used to reduce the high-speed rotation from the PTO. The gears adjust the rotational speed and increase the torque.

- Function: The gearbox takes the high-speed input from the PTO and converts it into the appropriate speed (usually slower) for the augers or mixing paddles, while also increasing the torque to ensure efficient mixing of heavy feed materials.

Power Distribution to the Output Shaft

- Output Shaft: The gearbox’s output shaft is connected to the mixer’s augers or paddles. This shaft transmits the adjusted speed and torque to the mixing mechanism.

- Function: The output shaft drives the augers or paddles, which move and mix the feed ingredients inside the wagon. The rotation of these components ensures that the feed is uniformly mixed, preventing any clumping or segregation of ingredients.

Continuous Rotation and Mixing

- Augers or Paddles: As the output shaft turns, it drives the augers (screws) or paddles inside the mixing wagon. These rotating parts stir and blend the ingredients in the wagon, ensuring that all components are evenly distributed.

- Function: The rotation of the augers or paddles moves the feed ingredients around in a circular or helical motion. The mechanical action of these components ensures thorough mixing, even for bulky or heavy feed mixtures.

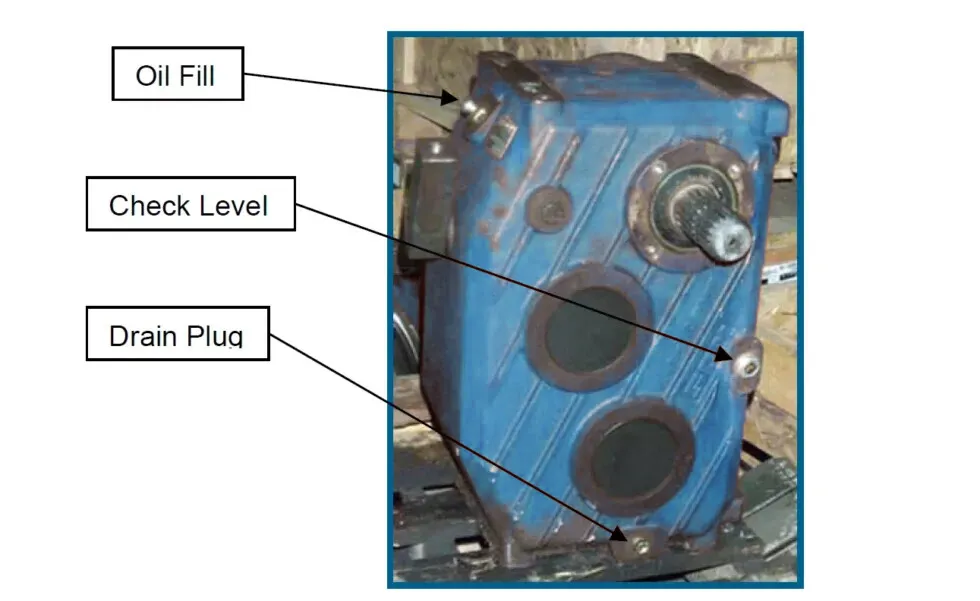

Lubrication and Cooling

- Lubrication System: The gearbox is equipped with an internal lubrication system (oil or grease) that ensures all moving parts remain properly lubricated during operation.

- Function: Lubrication reduces friction between the gears, ensuring smooth operation and minimizing wear and tear. This extends the life of the gearbox and maintains consistent performance. Some gearboxes also have a cooling system to prevent overheating during prolonged operation.

Summary of the Working Principle:

- Power Source: The PTO or engine provides rotational power to the gearbox.

- Speed and Torque Adjustment: The gearbox uses gears to adjust the speed and increase the torque.

- Power Transmission: The output shaft transmits the adjusted power to the mixing mechanism (augers or paddles).

- Mixing Process: The augers or paddles rotate, mixing the feed ingredients thoroughly.

- Lubrication & Cooling: Proper lubrication and cooling ensure efficient and smooth operation, extending the gearbox’s lifespan.

The feed mixer gearbox ensures that the mixing process is both efficient and consistent, allowing operators to achieve the desired feed consistency while minimizing energy loss and wear on the machinery.

|

|

The Importance of Feed Mixer Gearboxes in Mixing Wagons

Feed mixer gearboxes play a crucial role in the efficient operation of mixing wagons, which are essential for preparing balanced feed for livestock. These gearboxes are responsible for transferring power, controlling speed and torque, and ensuring that the feed is uniformly mixed. The importance of feed mixer gearboxes can be summarized in several key areas:

Efficient Power Transmission

- Optimal Power Transfer: The gearbox efficiently transfers mechanical energy from the tractor’s PTO (Power Take-Off) or an engine to the mixing wagon’s augers or paddles. By ensuring the right amount of power is delivered to the mixing components, the gearbox enables the system to work smoothly and efficiently.

- Importance: This ensures that the mixing process is not hindered by power loss or inefficiency, leading to consistent and uniform feed preparation.

Speed and Torque Control

- Precise Adjustment of Speed and Torque: The gearbox regulates the rotational speed and torque, allowing operators to adjust the mixing intensity based on the type and consistency of the feed. For instance, a higher torque setting is needed for dense or fibrous feed, while lighter feed may require faster but lower torque settings.

- Importance: This flexibility ensures that different types of feed, whether coarse, dry, or wet, are mixed correctly and uniformly, providing better nutritional consistency for livestock.

Durability and Longevity

- Robust Design and Durability: Feed mixer gearboxes are designed to withstand the stresses of continuous operation in harsh agricultural environments. They are built with durable materials and feature robust gears that handle the wear and tear from mixing large volumes of feed ingredients.

- Importance: The durability of the gearbox reduces the need for frequent maintenance and replacements, leading to lower operational costs and longer service life of the mixing wagon.

Improved Mixing Efficiency

- Enhanced Mixing Action: The gearbox ensures that the augers or paddles inside the mixing wagon rotate at an optimal speed, resulting in a thorough and consistent mix of ingredients. The even distribution of components in the feed ensures that livestock receive a balanced diet.

- Importance: Properly mixed feed is essential for the health and productivity of livestock. Uneven mixing can lead to nutritional imbalances, which can affect animal growth, milk production, and overall health.

Reduced Energy Consumption

- Energy Efficiency: The gearbox adjusts the speed and torque of the mixer to match the specific requirements of the feed being processed. By optimizing energy use, the gearbox minimizes waste and ensures that the energy from the PTO or engine is used efficiently.

- Importance: Reduced energy consumption not only lowers operating costs but also makes the mixing process more environmentally sustainable by reducing fuel consumption.

Feed mixer gearboxes are essential components in mixing wagons, enabling efficient, reliable, and flexible feed preparation. By optimizing power transfer, controlling speed and torque, ensuring durability, and promoting energy efficiency, the gearbox ensures that the feed mixer operates at peak performance. This ultimately leads to improved feed quality, reduced operational costs, and better overall livestock management. Without a properly functioning gearbox, the performance of the mixing wagon would be compromised, affecting both the efficiency of farm operations and the well-being of the animals.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX