Examples: JSZD120-12/15 motorized spindle is mainly used for small parts processing of non-ferrous metals. Customers own feeding mechanism, spindle hollow feeding, front elastic clamping, processing zero. lt has low roughness, good dimensional stability, and high efficiency.

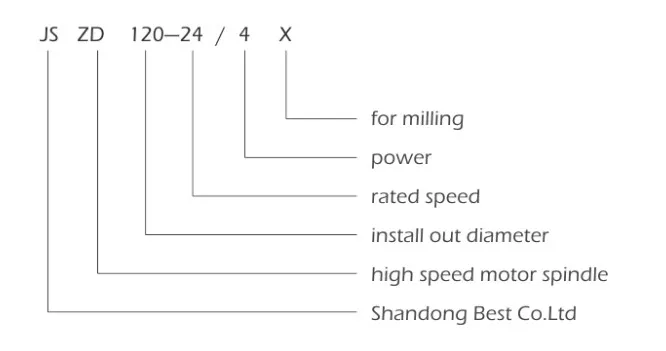

Nomenclature Explanation of Motor Spindle

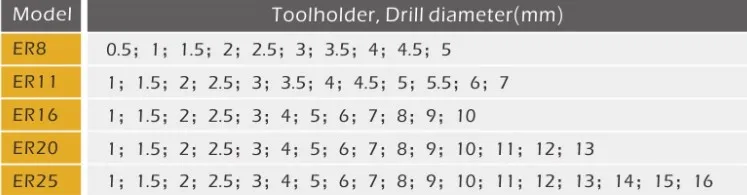

The End of the Spindle Connection

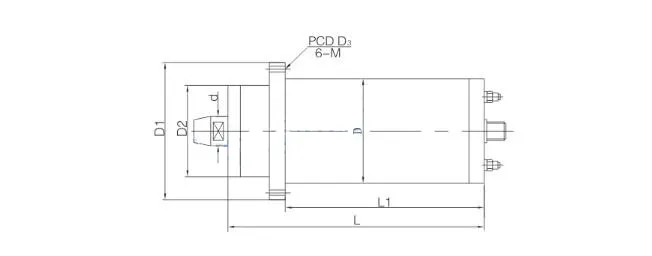

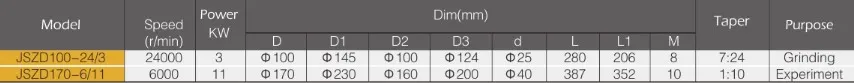

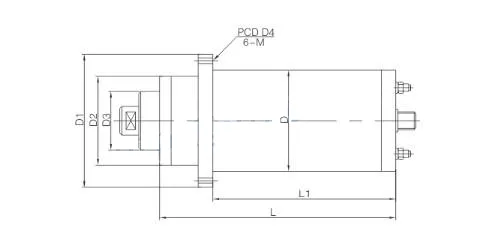

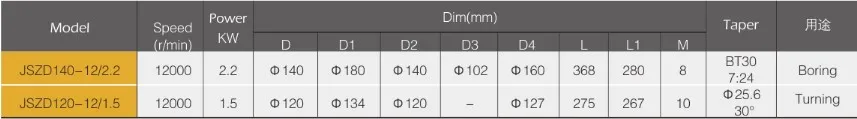

Its have many different types of connection, depending on the different model spindle, please refer to the table below.

Spindle Instruction

1. The frequency converter has to match the electric spindle unit. The basic frequency or even the nominal frequency as well as voltage will have to meet the technical parameters of the electrical spindle.

2. Electric spindle is generally cooled by circulating water. Cooling water needs to be rust-proof and filtered clean. When acquiring water, the inlet must be under the electric spindle.

three. When working with an oil mist lubricated spindle, the stress regulating valve on the oil mist gadget should be adjusted to 0.25~0.3 MPA the fog pressure should be 0.1~0.2 MPA and the variety of drops of oil must be 60-70 drops/min. and also the lubricating oil ought to be bell oil or turbine oil No. 20.

four. The velocity around the motorized spindle guide is definitely the highest velocity, and it can not be elevated, nevertheless, it may be employed to reduce

the pace, voltage, and frequency are reduced once the speed is lowered.

5. The rotation course with the motorized spindle is usually counter-clockwise (viewed in the shaft). except for exclusive

demands.

6. The motorized spindle lubricated by oil mist has to be linked with water and gasoline prior to it could possibly commence and cease water and fuel supply after shutdown.

Explanation: unique operation is required according to the electric spindle guidelines.

2. Electric spindle is generally cooled by circulating water. Cooling water needs to be rust-proof and filtered clean. When acquiring water, the inlet must be under the electric spindle.

three. When working with an oil mist lubricated spindle, the stress regulating valve on the oil mist gadget should be adjusted to 0.25~0.3 MPA the fog pressure should be 0.1~0.2 MPA and the variety of drops of oil must be 60-70 drops/min. and also the lubricating oil ought to be bell oil or turbine oil No. 20.

four. The velocity around the motorized spindle guide is definitely the highest velocity, and it can not be elevated, nevertheless, it may be employed to reduce

the pace, voltage, and frequency are reduced once the speed is lowered.

5. The rotation course with the motorized spindle is usually counter-clockwise (viewed in the shaft). except for exclusive

demands.

6. The motorized spindle lubricated by oil mist has to be linked with water and gasoline prior to it could possibly commence and cease water and fuel supply after shutdown.

Explanation: unique operation is required according to the electric spindle guidelines.

Author: CX