Double Disc Silage Machine Gearbox FMP-QZ115 Technical Data

Double Disc Silage Machine Gearbox FMP-QZ115 Technical Data

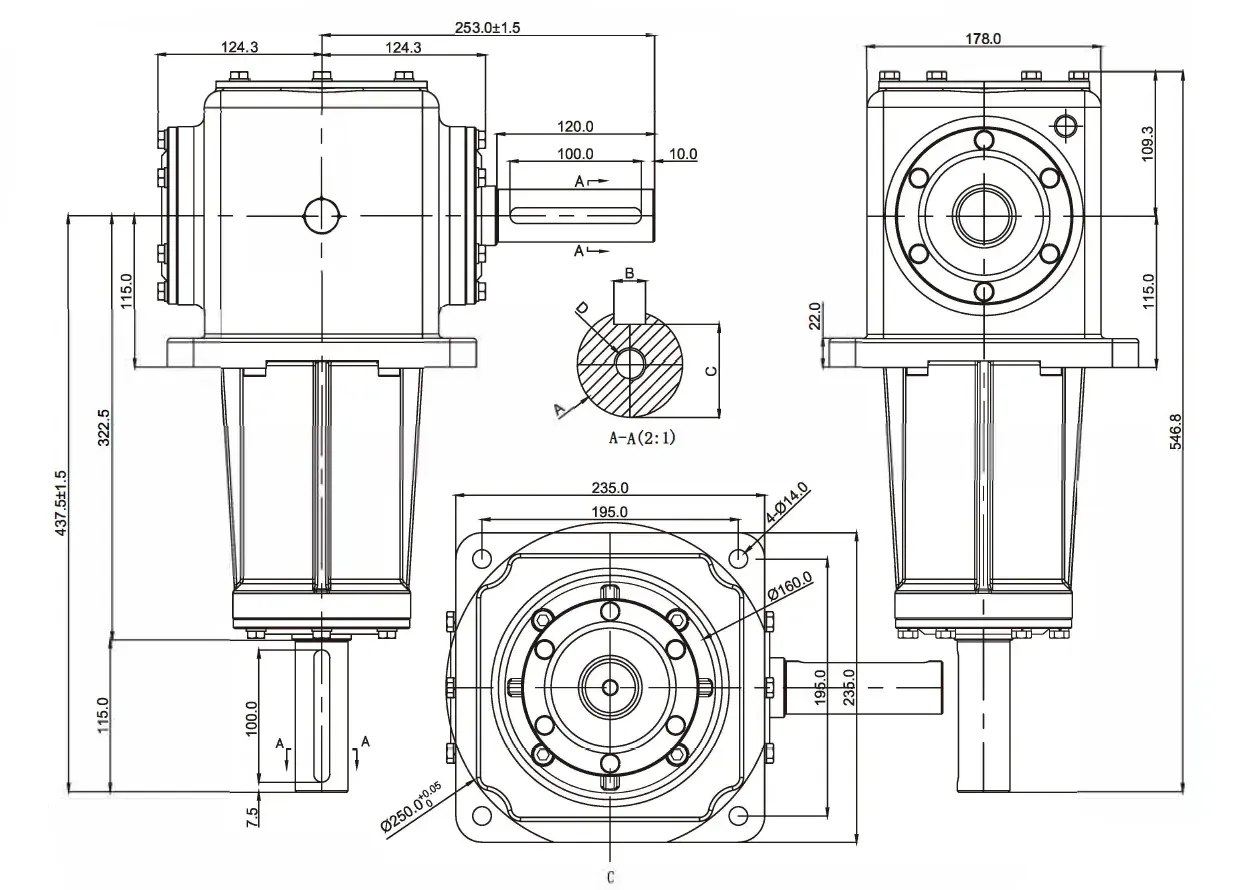

| i | Suitable | Rpm input | Rpm output | Output torque | Weight | Toothing | |

| r/min | r/min | N.m | kg | ||||

| Decelerate | 1: 1 | silage machines, etc | 1000 | 1000 | 580 | 35 | Gleason Helical Teeth |

| Remark: If you have any special require feel free let me know, we also accept custom. | |||||||

| A | B | C | D |

| Φ45 | 14 | 39.5 | M14 |

| Φ40 | 12 | 35 | M12 |

| Φ35 | 10 | 30 | M12 |

Advantages of Double Disc Silage Machine Gearbox FMP-QZ115

The Double Disc Silage Machine Gearbox FMP-QZ115 offers a range of advantages designed to improve the efficiency, reliability, and performance of silage harvesting operations. Specifically engineered for machines with dual cutting discs, this gearbox plays a key role in the silage harvesting process by ensuring smooth and precise operation. Here are the key advantages of the FMP-QZ115:

1. High Power Efficiency and Torque Transmission

- The FMP-QZ115 gearbox is designed to handle high-torque applications, providing efficient power transfer from the tractor’s PTO (Power Take-Off) shaft to the silage machine’s cutting discs.

- Its robust design ensures that the power is evenly distributed to both cutting discs, delivering consistent cutting force across the entire header.

- The gearbox minimizes power loss, maximizing the overall performance of the silage machine.

2. Precision Cutting for High-Quality Silage

- The dual disc system powered by the FMP-QZ115 gearbox enables the cutting of forage crops into uniformly sized pieces, essential for ensuring high-quality silage.

- The synchronized operation of the cutting discs provides precise and consistent chop length, which is critical for proper fermentation and optimal storage of silage.

- With precise cutting, the silage is better suited for digestion by livestock, improving the nutritional value of the feed.

3. Durability and Longevity

- The FMP-QZ115 gearbox is built with durable materials and advanced engineering, ensuring long-lasting performance even in demanding agricultural environments.

- It is designed to operate efficiently under harsh conditions, including high load, moisture, and dirt exposure, without compromising on reliability.

- The gearbox’s high-quality construction extends the lifespan of the machine, reducing the need for frequent repairs and maintenance.

4. Compact and Lightweight Design

- The FMP-QZ115 gearbox is compact and lightweight, making it easier to integrate into the silage machine without adding unnecessary weight or bulk.

- This contributes to the overall agility and maneuverability of the machine, enabling better handling and reducing operational strain on the tractor.

5. Reduced Maintenance Requirements

- The gearbox is engineered with a low-maintenance design, incorporating sealed bearings and advanced lubrication systems that reduce wear and tear on internal components.

- This minimizes downtime and reduces the overall cost of ownership by lowering maintenance and service needs.

- Self-lubricating features ensure that internal parts remain properly oiled, leading to smoother operation and increased reliability.

The FMP-QZ115 Double Disc Silage Machine Gearbox provides an exceptional combination of durability, precision, and efficiency, making it an ideal choice for modern silage harvesting operations. Its advanced features improve the overall silage quality, reduce maintenance costs, and increase the lifespan of both the gearbox and the machine, resulting in a more productive and cost-effective harvesting process.

Applications of Double Disc Silage Machine Gearbox FMP-QZ115

The FMP-QZ115 Double Disc Silage Machine Gearbox is specifically designed to enhance the performance and efficiency of silage harvesting operations. Its robust engineering and precision features make it suitable for a wide range of agricultural applications. Below are the key applications of the FMP-QZ115 gearbox:

1. Silage Harvesting

- The FMP-QZ115 gearbox is primarily used in silage harvesting machines, where it powers the dual cutting discs responsible for chopping forage crops into small, uniform pieces. These finely chopped pieces are then processed and stored as silage.

- The gearbox ensures that the power from the tractor’s PTO (Power Take-Off) is efficiently transmitted to both cutting discs, delivering consistent and reliable performance during the silage harvesting process.

2. Forage Cutting and Chopping

- The gearbox is integral to machines that chop a variety of forage crops, including corn, grass, alfalfa, and other silage-friendly plants.

- It enables precise and uniform cutting, which is essential for ensuring the quality and consistency of silage. The uniformity of chop length improves the fermentation process and overall nutritional value of the silage, making it a key tool for both small-scale and large-scale forage production.

3. Multi-Disc Forage Harvesters

- The FMP-QZ115 is especially suited for multi-disc forage harvesting systems, where it powers two cutting discs simultaneously. This ensures synchronized operation, allowing for efficient and uniform crop processing.

- By driving multiple discs in unison, the gearbox improves cutting precision and increases the productivity of the entire silage machine.

4. Haylage Production

- The gearbox can also be used in the production of haylage, which is made by chopping and storing grass or legumes at higher moisture content than traditional hay.

- The FMP-QZ115 ensures that the cutting mechanism can process the wetter material typically associated with haylage production without sacrificing efficiency or cutting quality.

5. High-Torque Agricultural Applications

- Designed to handle high-torque demands, the FMP-QZ115 gearbox is ideal for heavy-duty agricultural tasks, such as cutting dense, fibrous crops or thick stalks. Its robust construction ensures that it can process challenging materials like mature corn stalks or woody forage, providing high torque without compromising on performance.

- Its high torque capabilities make it suitable for use in high-demand harvesting environments where consistent, reliable power is essential.

The FMP-QZ115 Double Disc Silage Machine Gearbox is essential for improving the efficiency, reliability, and precision of silage harvesters. Its adaptability to a variety of crops, its ability to handle high-torque applications, and its versatile design make it a valuable component for agricultural operations looking to optimize silage production, whether on a small or large scale.

About FMP

Headquartered in Italy, FMP is a premier manufacturer renowned for its expertise in designing, developing, and producing high-performance gearboxes, with a particular emphasis on the agricultural machinery sector. FMP is recognized for its precision engineering, innovative solutions, and unwavering reliability, establishing itself as a trusted partner to industries both agricultural and industrial. Our comprehensive product portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide range of essential components, all tailored to meet the diverse requirements of various applications.

At FMP, we understand that each client faces unique challenges and needs. That’s why we specialize in providing tailored solutions, whether for individual components or fully integrated systems. By working closely with our customers, we ensure that every solution not only addresses their specific requirements but also optimizes performance and adds significant value. Our dedication to swift, professional responses and expert guidance guarantees that each inquiry is handled with precision, ensuring the best outcomes every time.

We place a strong emphasis on transparent and ongoing communication throughout the entire product development process. Our experienced team works directly with clients to gain a deep understanding of their needs, offering insightful recommendations to ensure optimal results. Whether we are crafting cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions that consistently meet deadlines. Our mission is to exceed client expectations by providing exceptional service and results with every project.

At FMP, quality is the cornerstone of everything we do. We uphold the highest manufacturing standards and employ stringent quality control measures to ensure that each product not only meets but surpasses industry standards. This commitment to excellence, coupled with our core values of integrity, teamwork, and perseverance, has enabled us to build strong, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always eager to foster global partnerships and remains dedicated to offering expert advice and customized solutions that address the evolving needs of our clients. We go beyond simply supplying products; we aim to establish long-term partnerships that contribute to the success of each project. Whether you require innovative solutions for a new initiative or ongoing support for an existing system, FMP is ready to help you navigate your technical challenges and ensure your continued success.

Author: CX